A flywheel battery structure for an h-type electric vehicle

A flywheel battery, electric vehicle technology, applied in electric vehicles, electric components, motors, etc., can solve the problems affecting the stability of the flywheel battery system, the large axial length of the energy storage device, the large volume of the flywheel battery, etc., to suppress the gyro effect. , Enhance the system stability, the effect of large moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

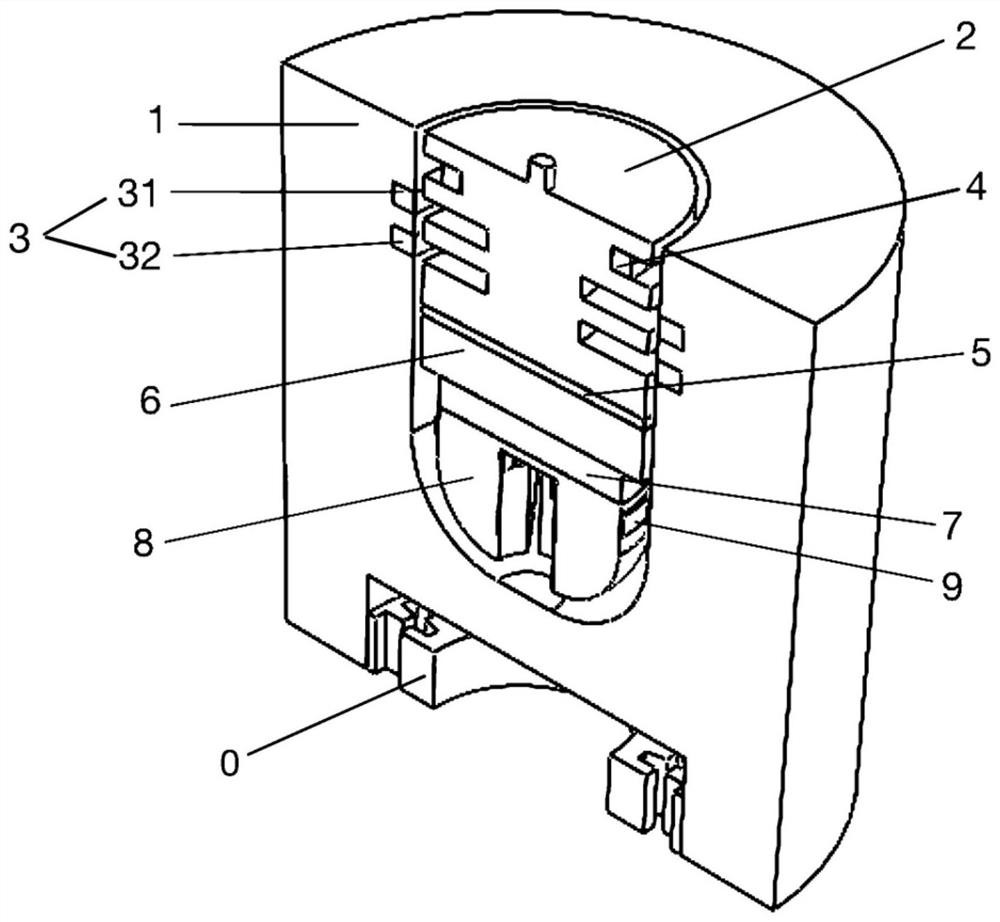

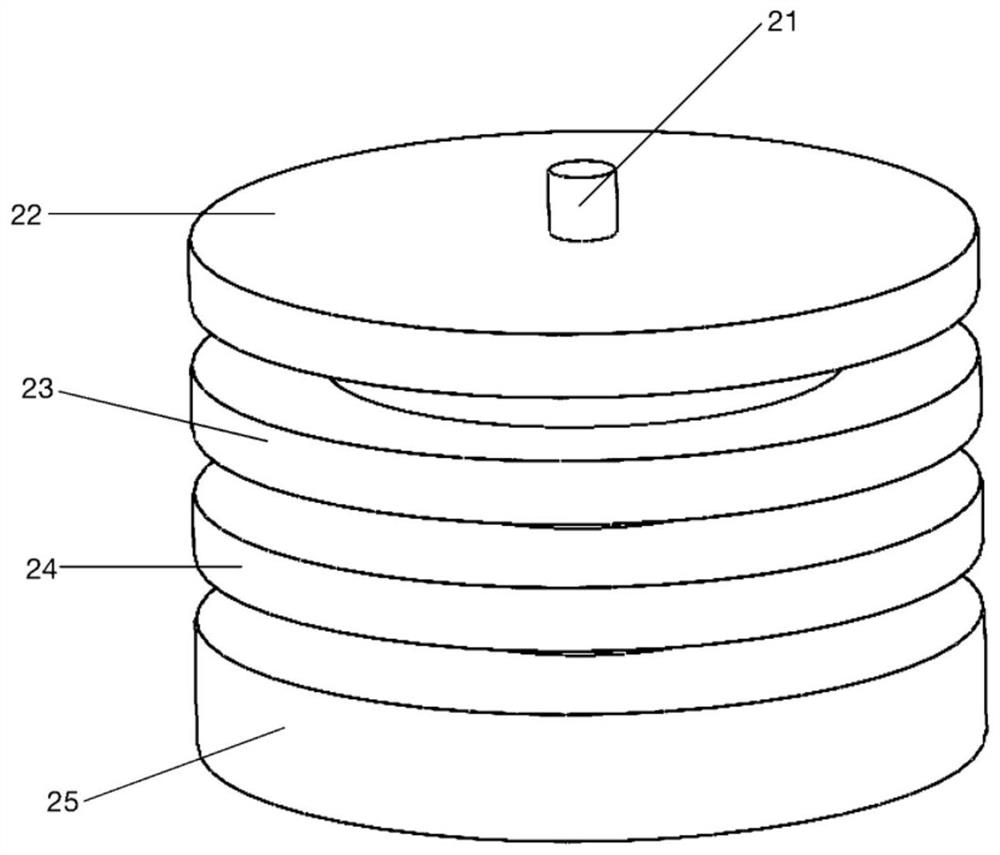

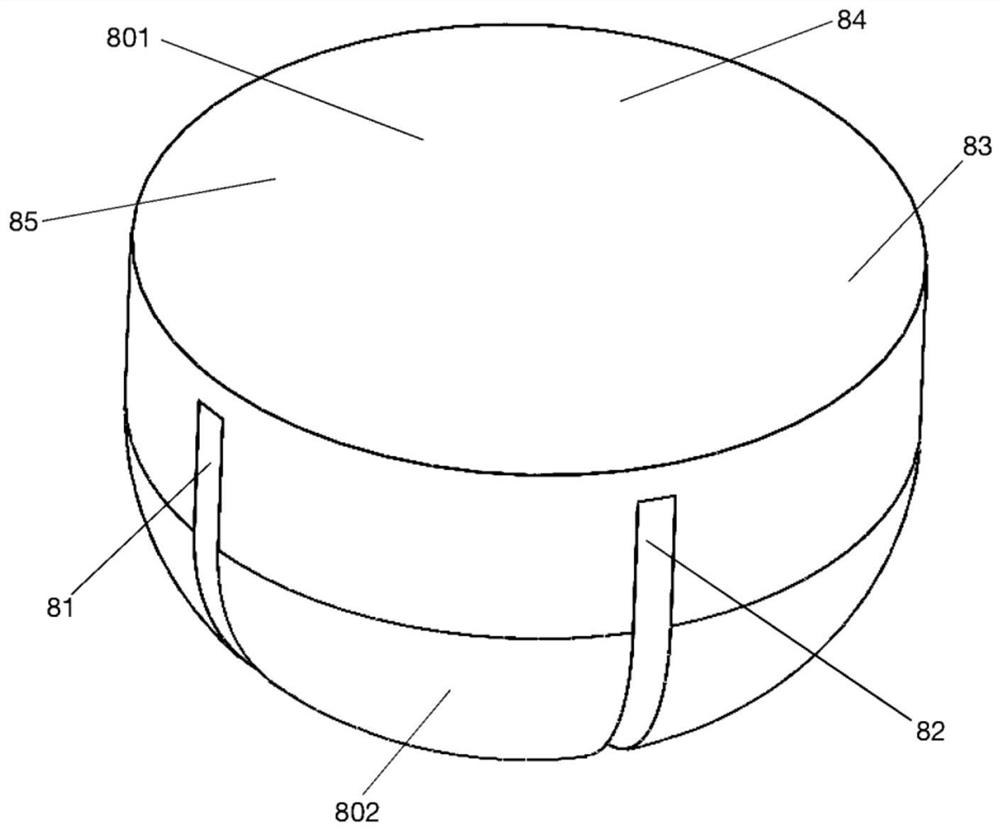

[0025] like figure 1 As shown, a flywheel battery structure for an H-type electric vehicle of the present invention includes a flywheel rotor casing 1, a stator shaft system 2, a permanent magnet 3, a radial winding 4, a magnetic isolation aluminum disc 5, a system connecting shaft 6, and a magnetic isolation aluminum Column 7, axial magnetic bearing core 8, axial winding 9 and motor / generator 0. like Image 6 As shown, the flywheel rotor casing 1 is cylindrical, the upper inner end is processed with an upper concave column 101, and the lower part of the upper concave column 101 is processed into a spherical surface 102, and the section of the upper concave column 101 and the spherical surface 102 is a U-shaped structure. Processed into the lower concave column 103, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com