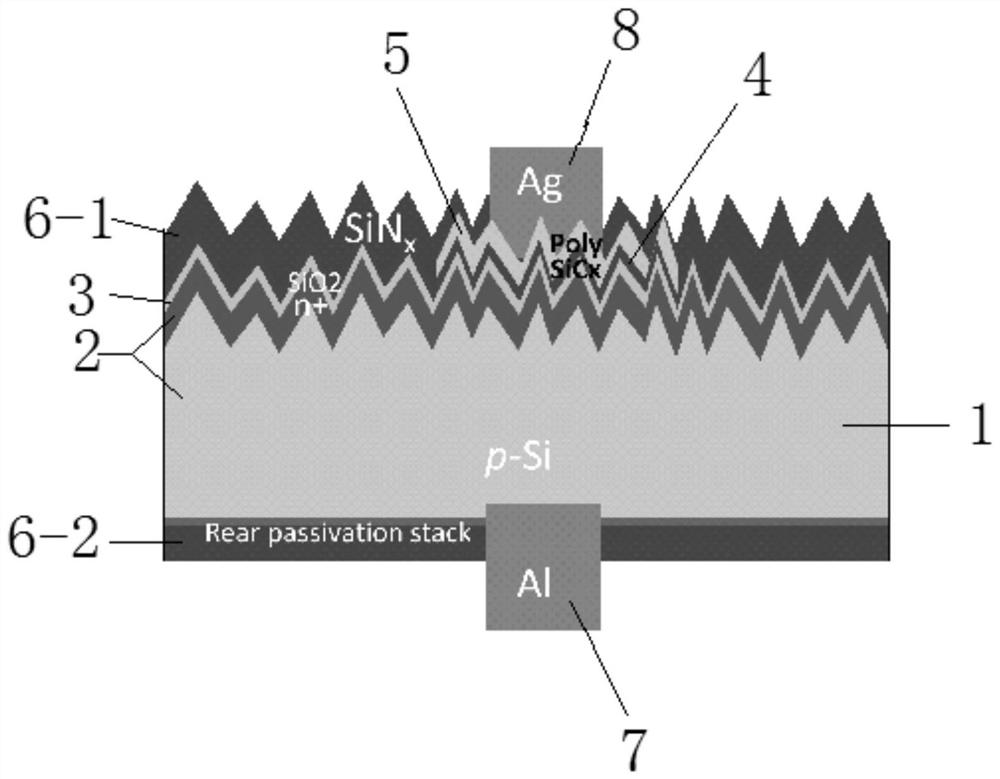

A double-layer passivation film for front contact passivation and preparation method thereof

A technology of front contact and passivation film, which is applied in the field of solar cells, can solve problems such as limiting the efficiency of PERC cells, and achieve the effect of less parasitic absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a double-layer passivation film for front contact passivation, said preparation method comprising the following steps:

[0030] (1) Texturing. With the P-type single crystal silicon wafer 1 as the silicon substrate, the texturing treatment is first performed, and the solution used is usually a KOH solution, and the KOH solution is based on KOH: additive: H 2 The ratio of O=20:3:160 is prepared, and the temperature is 80°C. Then wash in 2-5% HF solution to clean the surface of the silicon wafer;

[0031] (2) Phosphorus diffusion. In a conventional phosphorus diffusion furnace tube, a phosphorus diffusion process is performed to form a pn junction 2 . The diffusion temperature is between 700-900 degrees, and the formed sheet resistance ranges from 80-200ohm / □.

[0032] (3) Remove the back knot. First protect the front with water film, in HF / HNO 3 Remove the phosphosilicate glass and the back diffusion layer in the back surface field area in ...

Embodiment 2

[0041] A preparation method for a double-layer passivation film for front contact passivation, said preparation method comprising the following steps:

[0042] (1) Texturing. With the P-type single crystal silicon wafer 1 as the silicon substrate, the texturing treatment is first performed, and the solution used is usually a KOH solution, and the KOH solution is based on KOH: additive: H 2 The ratio of O=20:3:140 is prepared, and the temperature is 80°C. Then wash in 2-5% HF solution to clean the surface of the silicon wafer;

[0043] (2) Phosphorus diffusion. In a conventional phosphorus diffusion furnace tube, a phosphorus diffusion process is performed to form a pn junction 2 . The diffusion temperature is between 700-900 degrees, and the formed sheet resistance ranges from 80-200ohm / □.

[0044] (3) Remove the back knot. First protect the front with water film, in HF / HNO 3 Remove the phosphosilicate glass and the back diffusion layer in the back surface field area in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com