Method for electromagnetic non-destructive detection of microstructure of dual-phase steel

A technology of microstructure and non-destructive testing, which is applied in the direction of material analysis, measuring devices, and material magnetic variables through electromagnetic means, and can solve the problems of empirical data correlation, fuzzy relationship, and complicated detection parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

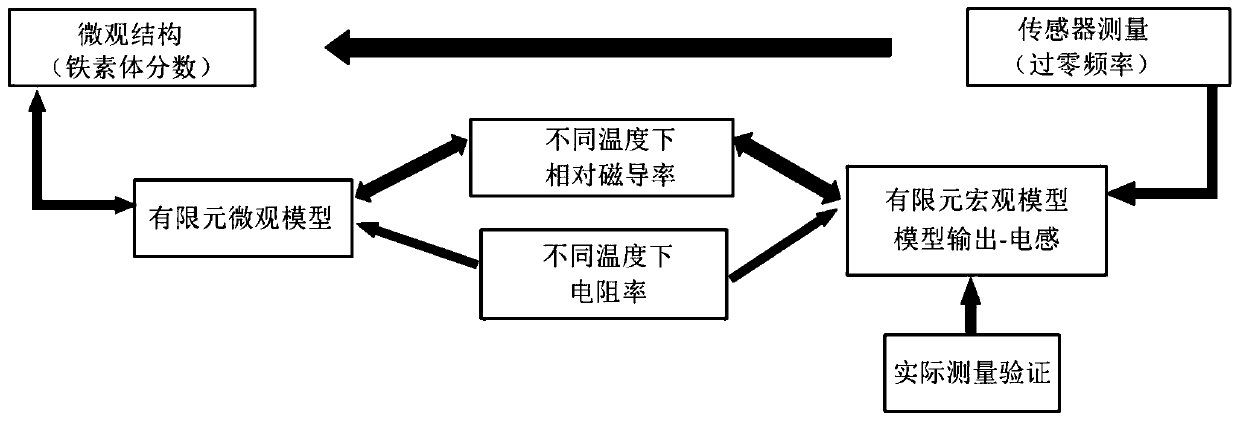

[0023] combined with Figure 1~5 , a method for electromagnetic nondestructive testing of the microstructure of dual-phase steel, comprising the following steps:

[0024] (1) According to the actual metallographic photos, extract and quantify the microstructure, including:

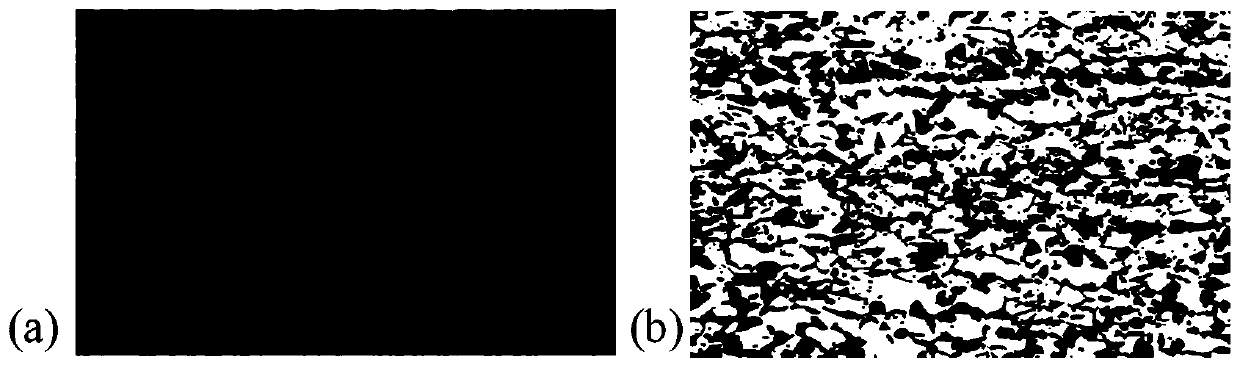

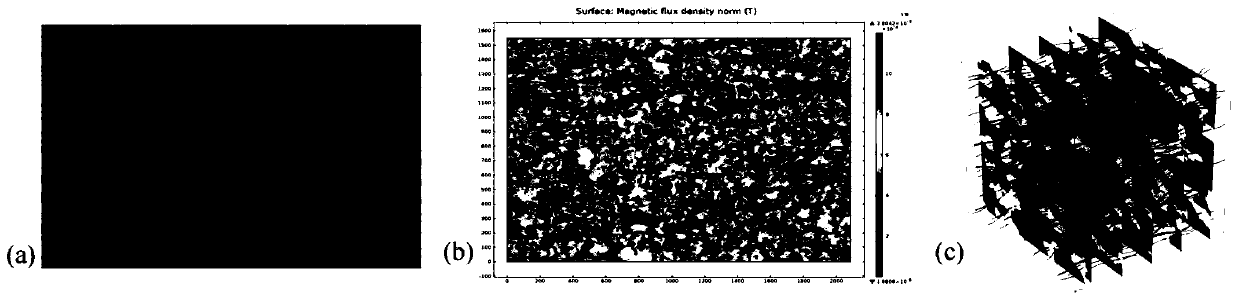

[0025] Obtain the actual metallographic photos of different phase contents, carry out the binarization processing of the images, import the obtained data into the finite element software to establish the microcosmic model, combine the attached figure 2 .

[0026] (2) Establish a finite element microcosmic-permeability model of steel with different ferrite phase fractions, and obtain the relationship between relative permeability-ferrite fraction-temperature through simulation calculations, including:

[0027] Since each metallographic photo contains 100,000 pixels, different colors can be used in the model to distinguish different phases in the microstructure, such as ferrite is red, pearlite is blue, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com