Sintering method of vanadium-titanium magnetite concentrate

A technology of vanadium titanomagnetite concentrate and sintering method, which is applied in the field of vanadium titanomagnetite concentrate preparation, can solve the problems of difficulty in sintering, low liquid phase formation, and high liquid phase formation temperature, so as to increase the liquid phase formation and increase viscosity. Phase formation and strength enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

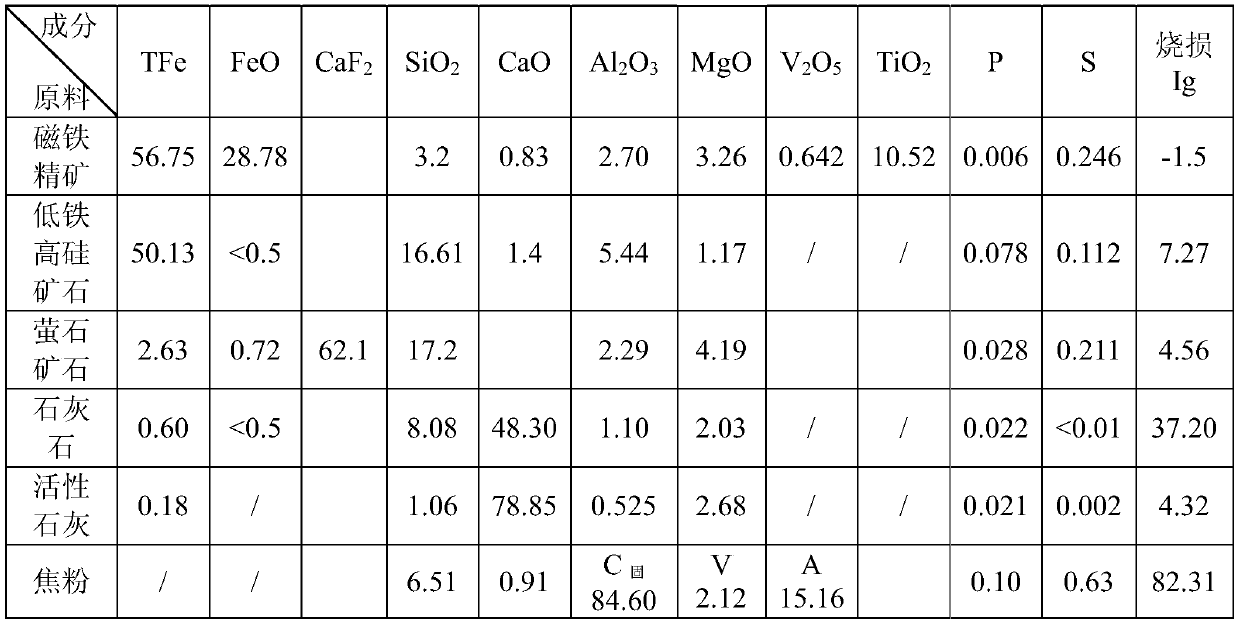

[0020] First carry out material mixing in the following range by weight:

[0021] A. Crush medium-grade common ore to <3mm powder, with a ratio of 5-10%.

[0022] B. Crush the fluorite ore to a powder of <3mm, with a ratio of 1-5%.

[0023] C. Crush the limestone and active lime to a powder of 6%, and the limestone is adjusted according to the difference of sintering alkalinity, and the general proportion is 3-8%.

[0024] D. Control the particle size of the coke powder to <5mm, and its proportion is 4.5-5%.

[0025] E. The particle size of vanadium-titanium magnetite concentrate is -200 mesh>80%, and the ratio of vanadium-titanium magnetite concentrate is 65-75%.

[0026] The above materials are mixed with water according to the ratio. The water content of the mixture is 7.2%-7.6%, the fixed carbon is 3.0-3.3%, the alkalinity R0 of the mixture is 1.8-2.4, and the height of the material layer is 750-850mm. The first time of mixing and granulation is 4±1min, and the second t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com