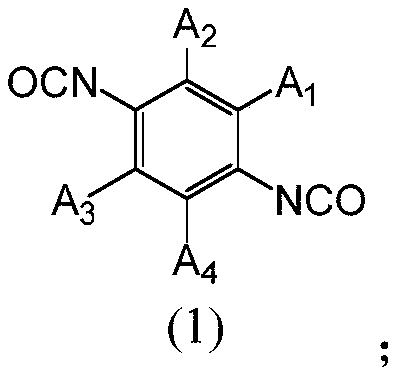

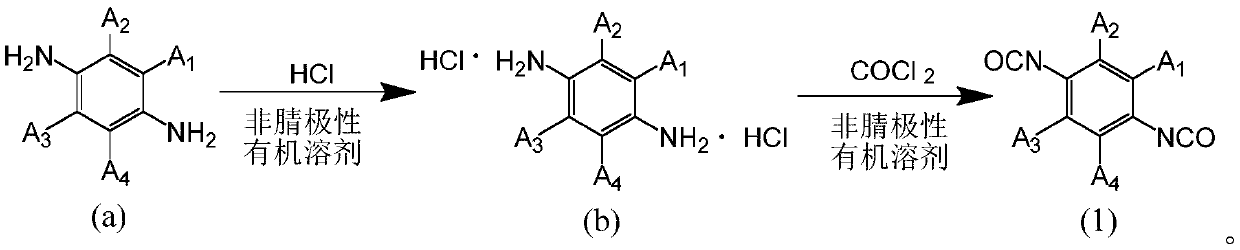

Preparation method of substituted 1,4-phenylene diisocyanate and application of non-nitrile polar organic solvent in preparation of substituted 1,4-phenylene diisocyanate

A technology of p-phenylenediisocyanate and organic solvent, applied in the field of fine chemical industry, can solve the problems of complicated steps, unstable yield, large amount of waste water, etc., and achieve the effects of improving reaction conditions, reducing production cost and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to facilitate the understanding of the purpose, technical solutions and key points of the present invention, the implementation manners of the present invention will be further described in detail below. This invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein. Rather, this embodiment is provided so that this invention will be thorough and complete and will fully convey the concept of the invention to those skilled in the art, and the present invention will only be defined by the appended claims.

[0035] Unless otherwise specified, the raw materials used in the examples of the present invention are commercially available.

[0036] This embodiment provides the application of a non-nitrile polar organic solvent as a reaction solvent for substituted p-phenylene diisocyanates.

[0037] Substituted p-phenylenediisocyanate is usually carried out in a tubular reactor by using the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com