A kind of synthetic method of 1,4-dihydroxyanthraquinone leuco

A technology of dihydroxyanthraquinone and synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of unguaranteed process safety, rising procurement and storage costs, insufficient stability of hydrosulfites, etc. To achieve the effect of shortening the reaction maintenance time, good economic and environmental benefits, qualified and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

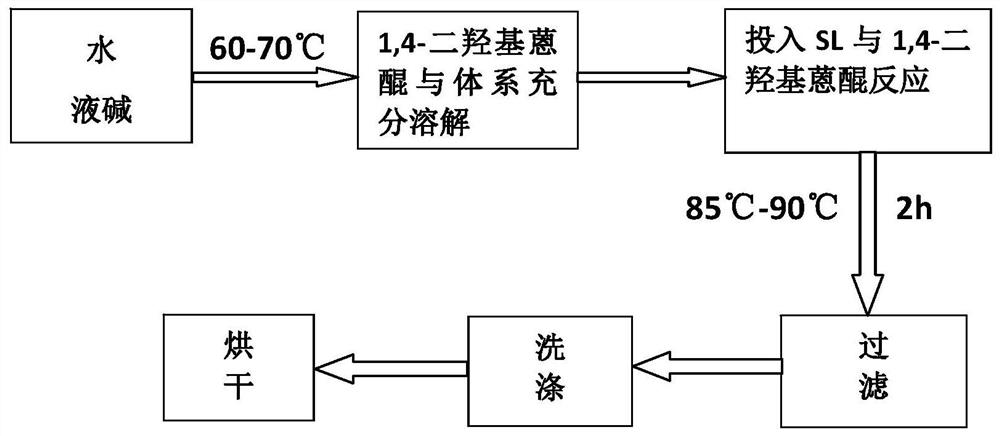

Method used

Image

Examples

Embodiment 1

[0020] This example provides a kind of synthetic method of 1,4-dihydroxyanthraquinone leucosome, and it comprises the following steps:

[0021] (a) Add 60ml of water, 20g of 30% liquid caustic soda, and 20g of 1,4-dihydroxyanthraquinone in sequence in a four-neck flask, heat up and stir, and keep the temperature at 70°C~75°C for 30min to make 1,4-dihydroxyanthraquinone Quinone and fully dissolved;

[0022] (b) Slowly add 6g of thiourea under stirring. After SL is added, raise the temperature to 88°C for 2 hours, cool down, and detect the reaction end point by HPLC; after the end point is reached, filter, wash with hot water until neutral, and dry the filter cake to obtain the finished product 19.2 g, content 95.64%, yield 96.0%.

Embodiment 2

[0024] This example provides a synthesis method of 1,4-dihydroxyanthraquinone leucosome, which is basically the same as that in Example 1, the difference is that the amount of water added in step (a) is 120ml, and finally filtered and washed with hot water To neutrality, the filter cake was dried to obtain 18.6g of finished product, the content was 95.22%, and the yield was 93.0%.

Embodiment 3

[0026] This example provides a kind of synthetic method of 1,4-dihydroxyanthraquinone leucosome, which is basically the same as that in Example 1. The difference is that the input amount of liquid caustic soda in step (a) is 30g, and finally after filtering, heat Wash with water until neutral, and dry the filter cake to obtain 17.8 g of the finished product, with a content of 96.13% and a yield of 89.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com