Bionic intelligent surface 3D printing method with controllable resistance and wettability

A 3D printing and wettability technology, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., to achieve the effect of intelligent characteristics, simple process and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

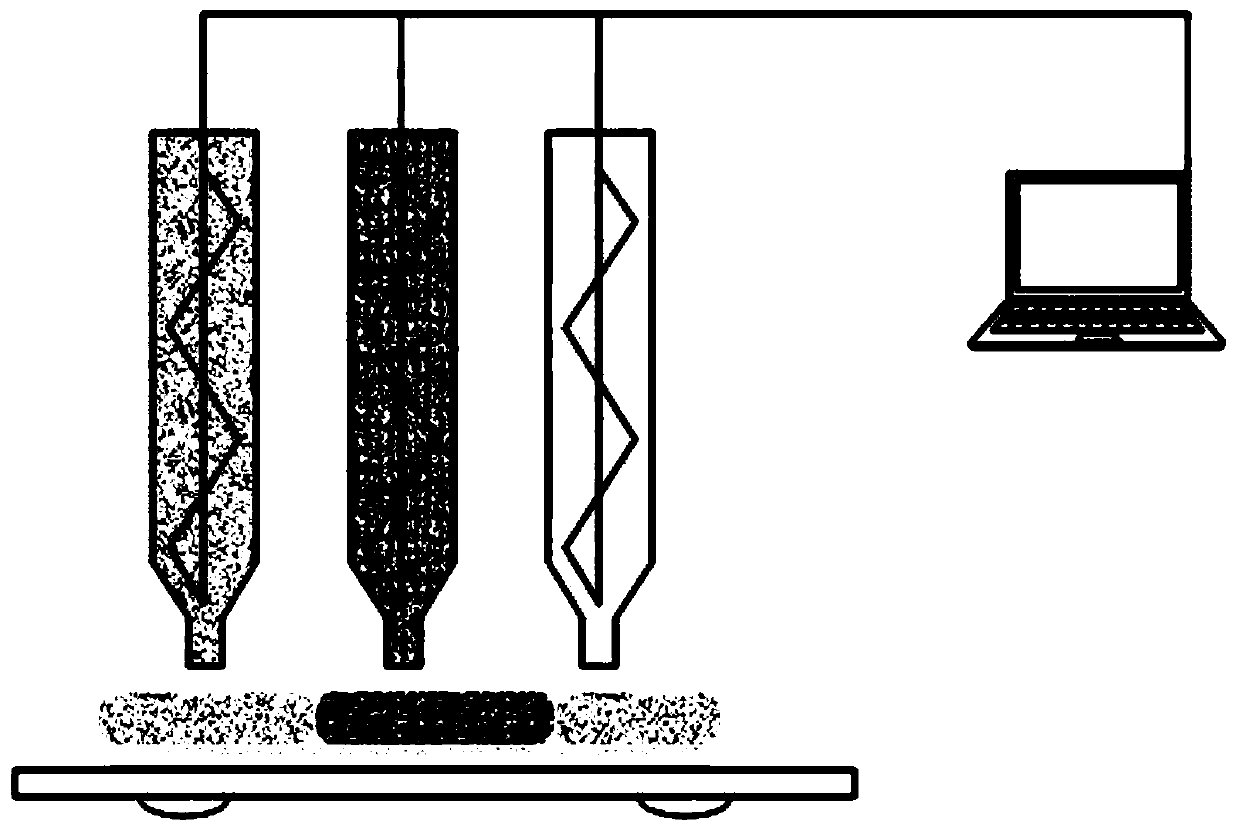

Image

Examples

Embodiment 1

[0045] The design and manufacture of a microfluidic non-mechanical drive valve device realized by the present invention, the specific technical scheme is as follows:

[0046] A. Material composition and preparation

[0047] Component 1: poly 2-vinylpyridine (P2VP-COOH) (95wt.%), magnetic fiber (or magnetized fiber) after coupling agent treatment (fiber diameter is 5-13 μm, aspect ratio is 4 -15) (4.5 wt.%) and fumed silica (0.5 wt.%).

[0048] Component 2: tert-butyl carboxyl-terminated polyacrylate (PBA-COOH) (95wt.%), magnetic fiber (or magnetized fiber) after coupling agent treatment (fiber diameter is 5-13 μm, aspect ratio is 4-15) (4.5 wt.%) and fumed silica (0.5 wt.%).

[0049] Component 3: polyglycidyl methacrylate (PGMA) (99.4 wt.%) fumed silica (0.6 wt.%).

[0050] The above components are mixed in proportion and ready for use.

[0051] B. Bionic intelligent surface molding

[0052] In this specific implementation case, the multi-material 3D printing molding method...

Embodiment 2

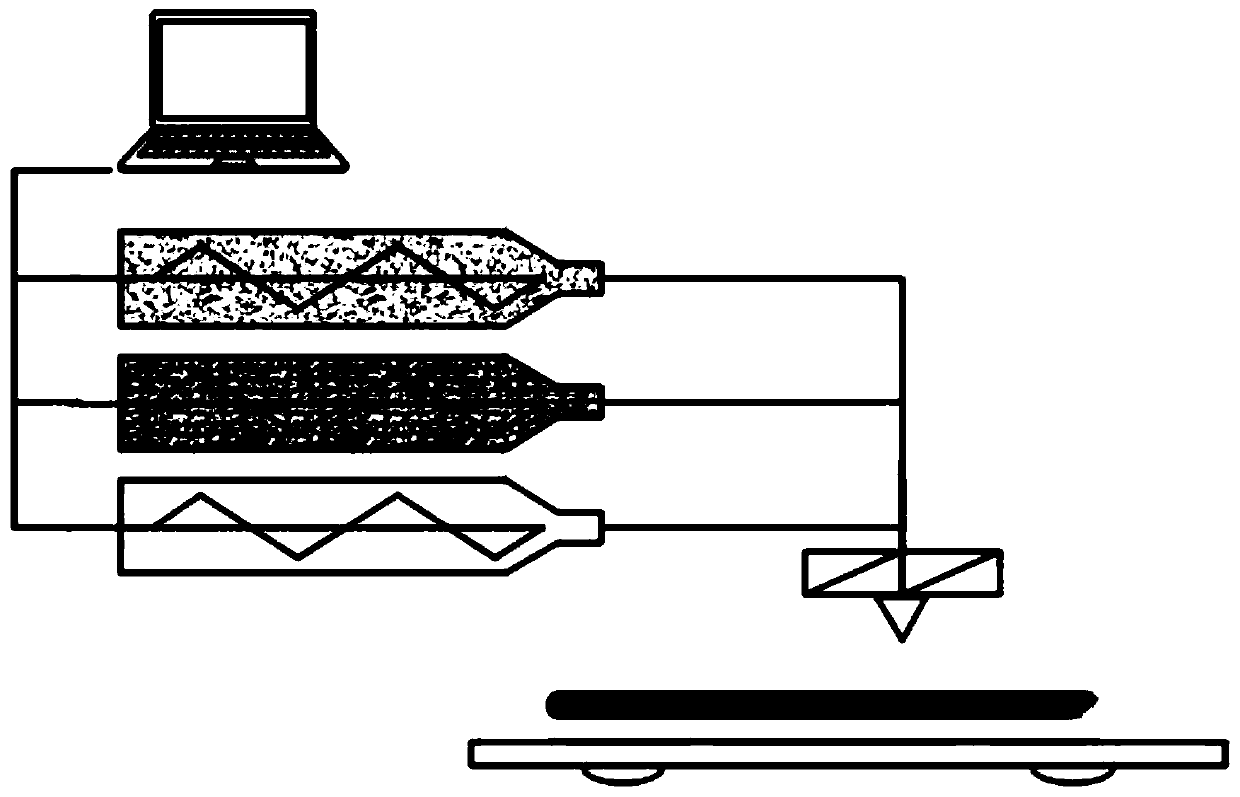

[0060] The design and manufacture of a smart surface with controllable liquid delivery path on inclined planes realized by the present invention, the specific technical scheme is as follows:

[0061] A. Material composition and preparation

[0062] Component 1: poly 2-vinylpyridine (P2VP-COOH) (94wt.%), magnetic fiber (or magnetized fiber) after coupling agent treatment (fiber diameter is 5-13μm, aspect ratio is 4 -15) (5.3 wt.%) and fumed silica (0.7 wt.%).

[0063] Component 2: tert-butyl carboxyl-terminated polyacrylate (PBA-COOH) (94wt.%), magnetic fiber (or magnetized fiber) after coupling agent treatment (fiber diameter is 5-13 μm, aspect ratio is 4-15) (5.3 wt.%) and fumed silica (0.7 wt.%).

[0064] Component 3: polyglycidyl methacrylate (PGMA) (99.5 wt.%) fumed silica (0.5 wt.%).

[0065] The above components are mixed in proportion and ready for use.

[0066] B. Bionic intelligent surface molding

[0067] In this specific implementation case, the gradient 3D pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com