Air valve in a ventilation and air conditioning system

A technology of air conditioning system and air valve, which is applied in the direction of lift valve, valve device, mechanical equipment, etc., to achieve the effect of reducing turbulent dissipation rate, reducing local resistance and good conformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

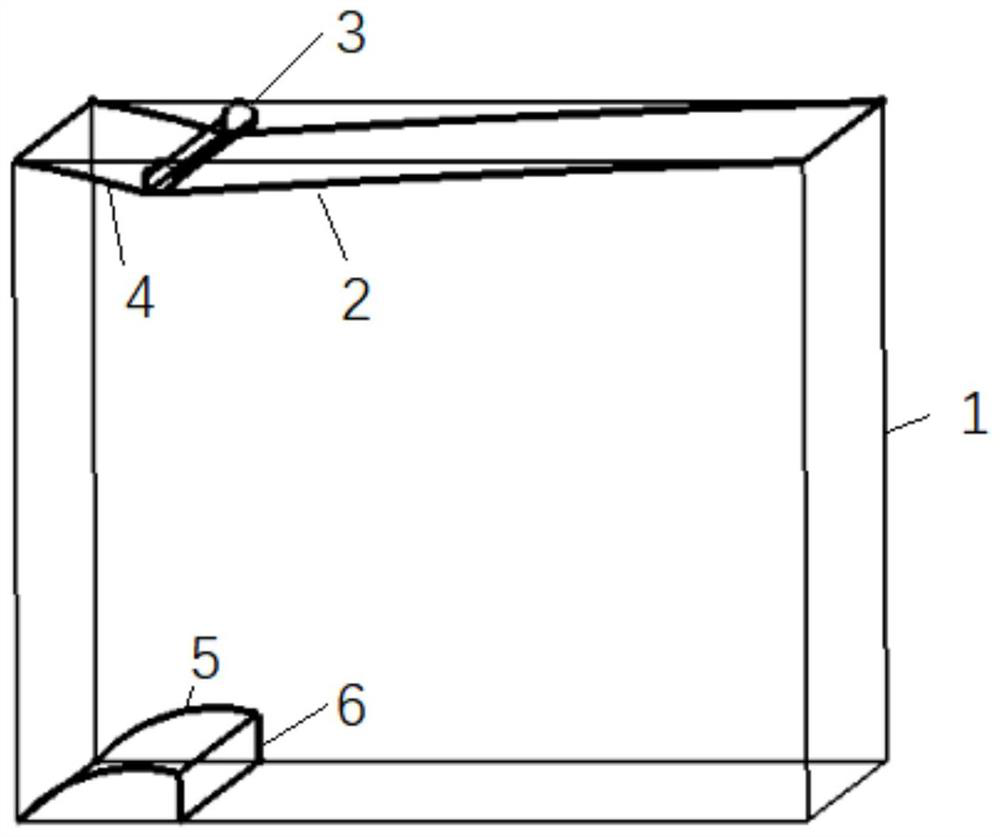

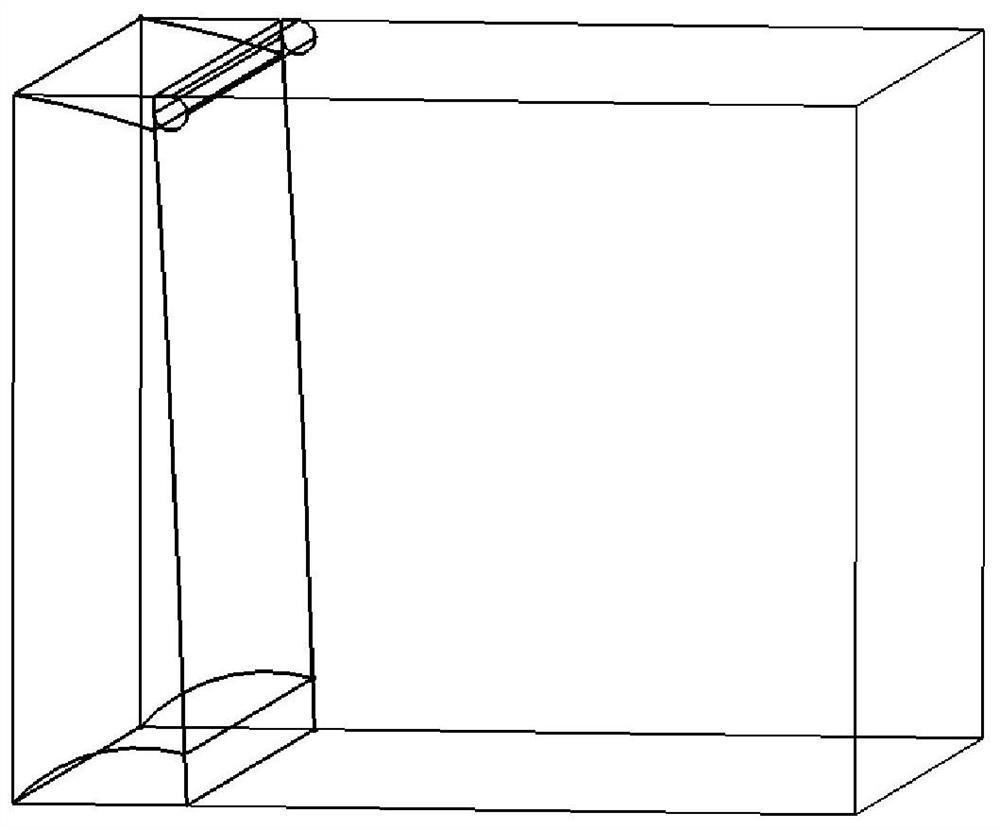

Embodiment 1

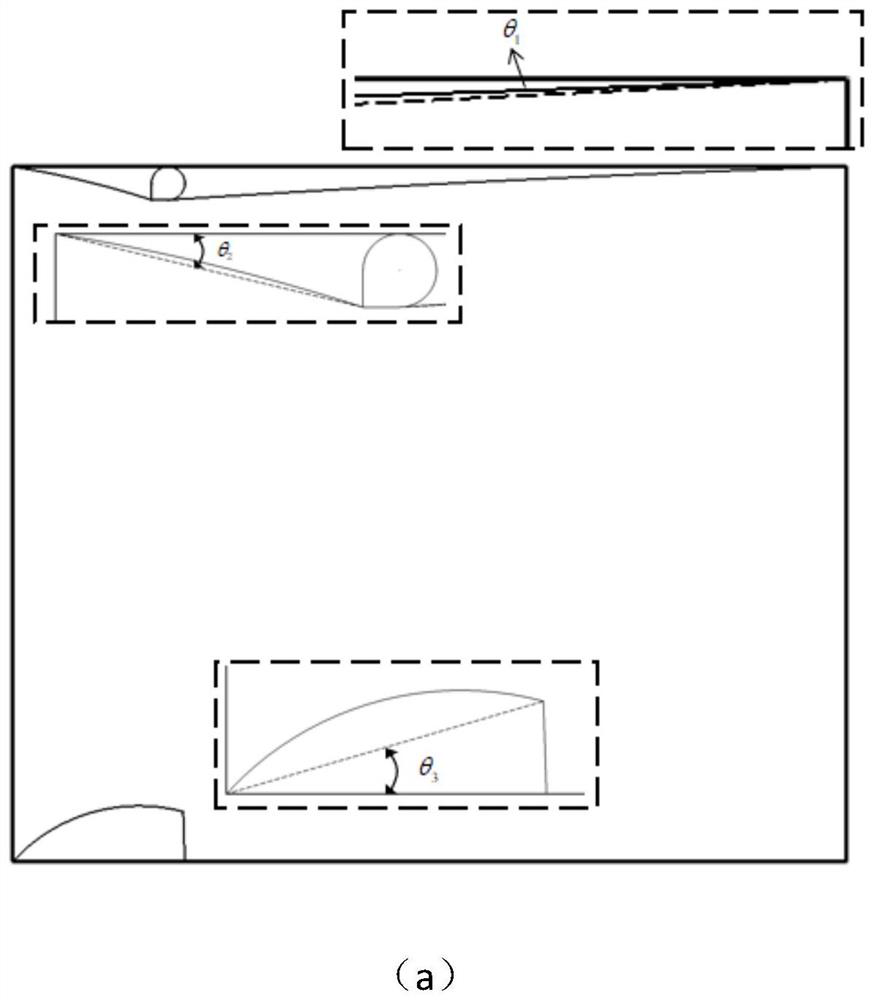

[0031] This embodiment proposes a new structure of a single-leaf valve. The valve plate is located on the upper part of the main body of the damper, the shaft is located on one side of the valve plate, and the upper and lower seals are located on the same side. When the damper is closed, the position of the valve plate is different from that of a conventional single-leaf valve. Specifically, the valve plate is located on the upper part of the damper body, the rotating shaft is located on the side of the valve plate, the first seal and the second seal are located on the fluid inlet side, when the valve plate rotates around the rotating shaft to the lower part of the damper body, the valve The plate is in contact with the second seal; and in the air valve proposed by the present invention, the first seal has a first curved surface, and the first curved surface is concave toward the fluid inlet side of the air valve; the second seal includes a second curved surface and an inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com