Cement particle board, and preparation process and application thereof

A preparation process and particleboard technology, applied to cement particleboard and its preparation process and application fields, can solve the problems of hindering the penetration and flow rate of adhesive liquid, limited application range of cement particleboard, poor direct veneer ability, etc., and achieve excellent Direct finishing ability, ensuring the overall physical and chemical properties, and enhancing the effect of finishing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

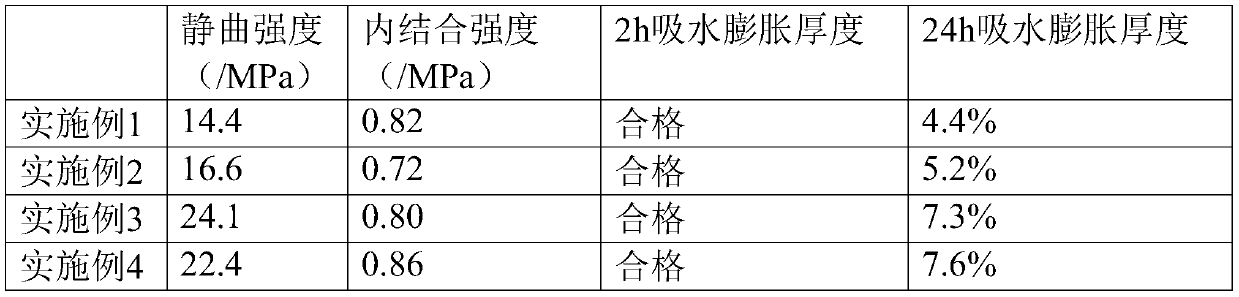

Examples

Embodiment 1

[0033] Embodiment 1 prepares cement particleboard

[0034] A kind of preparation technology of the present embodiment cement particleboard, comprises the following steps:

[0035] Air-dry the wood processing residues to a moisture content of 14-25%; then pass through a shredder and a planer (30-120mm in length, 5-20mm in width, and 0.20-0.80mm in thickness), and then pass through mechanical screening Rough wood shavings (length greater than 60mm) are used as core material, while 80% fine wood shavings (length less than 60mm) and 20% sawdust are used as surface material for subsequent use.

[0036] (1) Wood shavings are pretreated for subsequent use;

[0037] Specifically include: (a) immerse the corresponding wood shavings (i.e. coarse wood shavings / fine wood shavings+sawdust) in 1% sodium hydroxide solution for degradation treatment, take them out after 40-60 minutes, and wash until the rinse solution pH at 7-9, drain;

[0038] (b) Put the drained wood shavings into an ove...

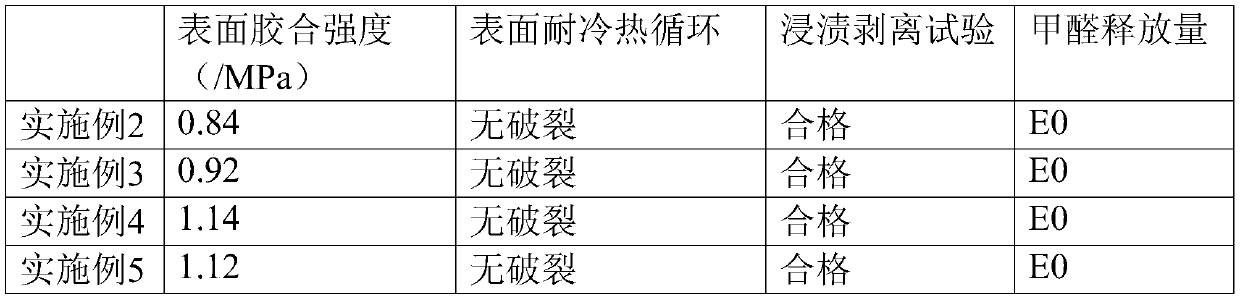

Embodiment 2

[0043] Embodiment 2 prepares facing particle board (cement particle board+tech wood+melamine paper)

[0044] A kind of preparation method of facing particle board of the present embodiment comprises the following steps:

[0045] (1) The cement particle board double-sided glue (melamine glue, 270g-300g / m2) prepared by embodiment 1 2 );

[0046] (2) Paste a piece of 50 silk technical wood on the upper and lower surfaces of the glued cement particle board, first cold press (the cold pressing pressure is 0.8MPa, and the cold pressing time is 4min) and then hot pressing (hot pressing temperature is 110°C) , the hot pressing time is 4.5min, and the hot pressing pressure is 1.0MPa);

[0047] (3) Lay melamine paper on the surface of high-tech wood, heat-press and solidify (hot-press temperature is 120°C, heat-press time is 7min, and heat-press pressure is 1.0MPa), and then unload it after mechanically cooling to 80°C to obtain The facing particleboard of this example.

Embodiment 3

[0048] Embodiment 3 prepares facing particle board (cement particle board+Okoume)

[0049] A kind of preparation method of facing particle board of the present embodiment comprises the following steps:

[0050] (1) The cement particle board double-sided glue (melamine glue, 270g-300g / m2) prepared by embodiment 1 2 );

[0051] (2) Paste a piece of 40 wire okoume on the upper and lower surfaces of the glued cement particle board, first cold press (the cold pressing pressure is 0.6MPa, the cold pressing time is 4min) and then hot pressing (hot pressing temperature is 110 -120°C, hot-pressing time 3.5min, hot-pressing pressure 0.8MPa), with mechanical cooling to 80°C and then unloading, the decorative particleboard of this embodiment is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com