Corrugated steel sheet having inclined portion in which position of coupling hole is adjusted and joint corrugated steel sheet structure using same

A corrugated steel plate and tilt adjustment technology, which is applied in the direction of thin plate connection, connection components, building components, etc., can solve the problems of inability to fasten bolts, failure to obtain joint strength, leakage, etc., to minimize space, stabilize bolt connection strength, and improve The effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

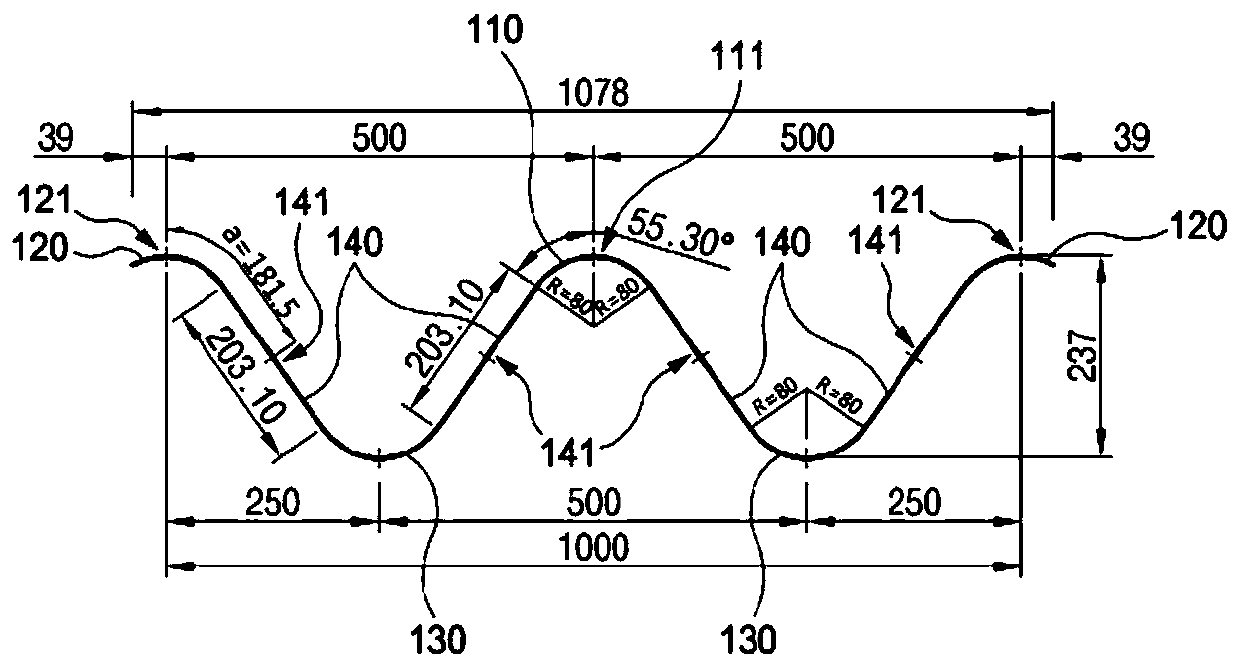

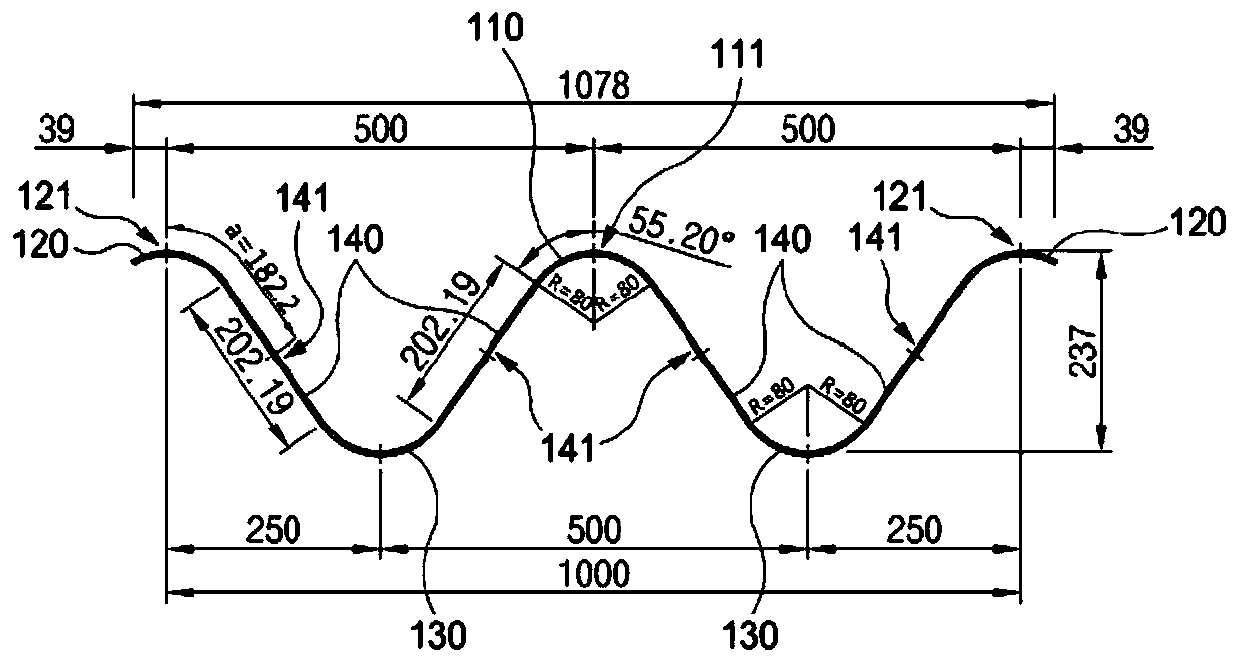

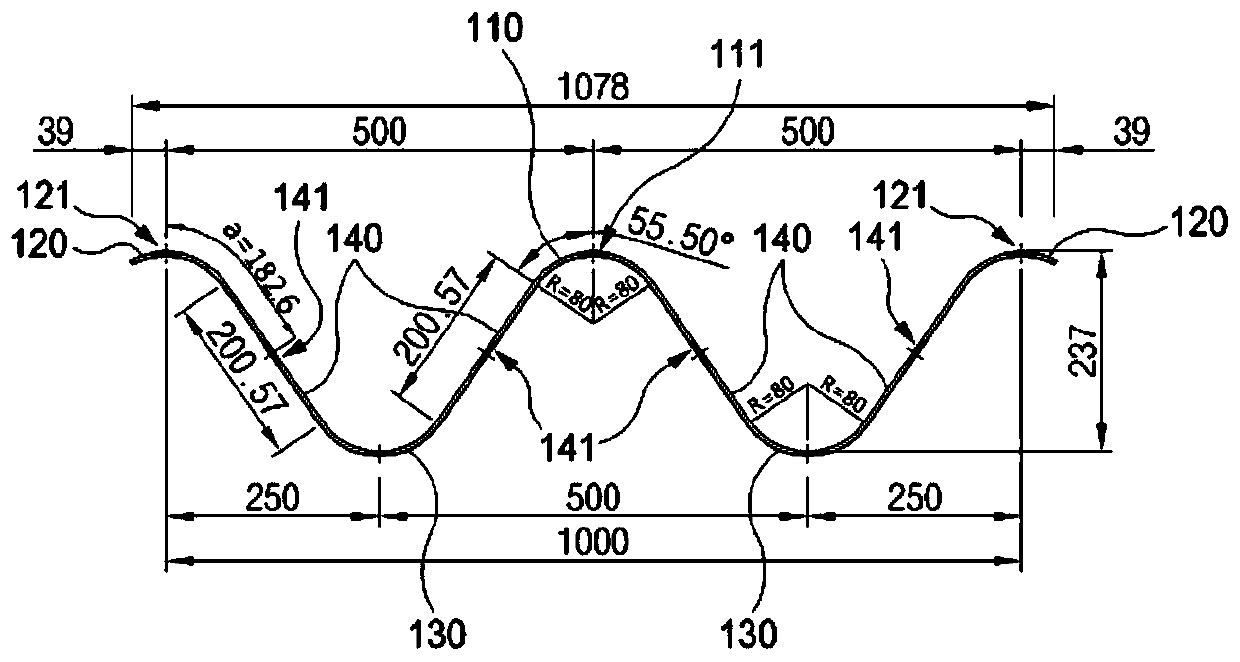

[0047] Such as figure 1As shown, the corrugated steel plate according to the present invention basically includes: a W-shaped main body 100 with a central top 110, two connecting tops 120, two valleys 130 and four inclined parts 140; connecting holes 111, 121, 131, 141, respectively formed at the central part of a central top 110, two connecting tops 120, two valleys 130 and four inclined parts 140, so that the corrugated steel plate B is corrugated by overlapping and connecting a pair of corrugated steel plates A and B Steel plate connection structure.

[0048] The upper corrugated steel plate A and the lower corrugated steel plate B are overlapped and connected to the upper part of the lower corrugated steel plate A, and the thickness is the same as that of the lower corrugated steel plate A, and the connecting holes of the lower corrugated st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com