Grouting fluid suitable for secondary lining backfill of water diversion tunnel and its preparation and application method

A technology for secondary lining and water diversion tunnels, applied in tunnel lining, wellbore lining, tunnels, etc., can solve problems such as water gushing in grouting holes, slurry running or channeling, and affecting the effect of grouting water blocking, achieving fast condensation speed and improving Early strength, the effect of improving the effect of grouting water plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

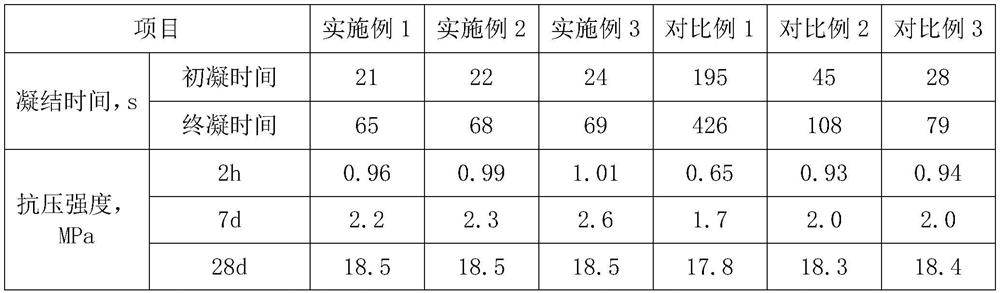

Examples

preparation example 1

[0042] Preparation example 1 of accelerator: ① Take 40kg of aluminum sulfate, add 50kg of water to it, and heat to 60°C to obtain aluminum sulfate suspension;

[0043] ②Take 10kg of calcium formate and 4kg of calcium chloride, add 30kg of water to it, heat to 40°C; stir evenly for 10min to obtain modifier;

[0044] ③Raise the temperature of the aluminum sulfate suspension to 60°C, add a modifier to the aluminum sulfate suspension, stir at a speed of 600r / min for 30min, keep it warm for 60min, then cool to room temperature, then add 1kg of sodium alginate and 0.5kg Sodium carboxymethyl cellulose, stirred evenly to obtain quick-setting agent.

preparation example 2

[0045] Preparation example 2 of quick-setting agent: 1. Take 45kg of aluminum sulfate, add 55kg of water to it, and heat to 65°C to obtain aluminum sulfate suspension;

[0046] ②Take 12.5kg of calcium formate and 5kg of calcium chloride, add 35kg of water to it, heat to 45°C; stir evenly for 15min to obtain modifier;

[0047] ③Raise the temperature of the aluminum sulfate suspension to 70°C, add a modifier to the aluminum sulfate suspension, stir at a speed of 700r / min for 35min, keep it warm for 75min, then cool to room temperature, then add 1.5kg of sodium alginate and 0.6 kg sodium carboxymethyl cellulose, stirred evenly to obtain quick-setting agent.

preparation example 3

[0048] Preparation example 3 of quick-setting agent: 1. Take 50kg of aluminum sulfate, add 60kg of water to it, and heat to 70°C to obtain aluminum sulfate suspension;

[0049] ②Take 15kg of calcium formate and 6kg of calcium chloride, add 40kg of water to it, heat to 50°C; stir evenly for 20min to obtain modifier;

[0050] ③Raise the temperature of the aluminum sulfate suspension to 80°C, add a modifier to the aluminum sulfate suspension, stir at a speed of 800r / min for 40min, keep it warm for 90min, then cool to room temperature, then add 2kg of sodium alginate and 0.7kg Sodium carboxymethyl cellulose, stirred evenly to obtain quick-setting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com