In-situ emulsification and viscosity increase system with controllable viscosity, and application thereof in water-flooding oil reservoir

A water-flooding and viscosity technology, which is applied in the fields of production fluids, drilling compositions, chemical instruments and methods, etc., can solve the problems of aggravating reservoir heterogeneity, difficult emulsion propagation, and high injection pressure, and achieves economical results. Outstanding benefits, good injectability, and the effect of improving seepage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 The oil-water interfacial tension of the in-situ emulsification viscosity-increasing system with controllable viscosity

[0037] The degree of salinity is prepared separately to be 0.5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.01×10 4 mg / L) No. 1#, 3×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.1×10 4 mg / L) No. 2#, 5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.5×10 4 mg / L) No. 3#, 10×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.0×10 4 mg / L) No. 4# and 24×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.5×10 4 mg / L) No. 5# mineralized water, stirred for 1 hour. Add 0.2% sodium petroleum sulfonate, 0.2% sodium dodecyl sulfonate, 0.15% ultrafine silicon dioxide, 0.05% partially hydrolyzed polyacrylamide in 1#; add 0.2% in 2# % fatty alcohol ether sodium carboxylate, 0.2% sodium dodecylbenzenesulfonate, 0.15% ultrafine montmorillonite, 0.05% hydroxymethyl cellulose; add 0.4% dodecyl cellulose in 3# in sequence Alkyl hydroxy sulta...

Embodiment 2

[0042] Example 2 Apparent Viscosity of In-Situ Emulsification and Viscosification System with Controllable Viscosity

[0043] The degree of salinity is prepared separately to be 0.5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.01×10 4 mg / L) No. 1#, 3×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.1×10 4 mg / L) No. 2#, 5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.5×10 4 mg / L) No. 3#, 10×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.0×10 4 mg / L) No. 4# and 24×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.5×10 4 mg / L) No. 5# mineralized water, stirred for 1 hour. Add 0.2% sodium fatty alcohol ether carboxylate, 0.2% sodium dodecylsulfonate, 0.15% ultrafine montmorillonite, and 0.05% amylose in 1#; add 0.2% in 2# % fatty alcohol ether sodium sulfonate, 0.2% sodium dodecylbenzene sulfonate, 0.15% ultrafine ferric oxide, 0.05% sodium alginate; add 0.4% alkanolamide in sequence to 3# , 0.15% superfine iron oxide, 0.05% hydroxymethyl cellulose; 0.4% lau...

Embodiment 3

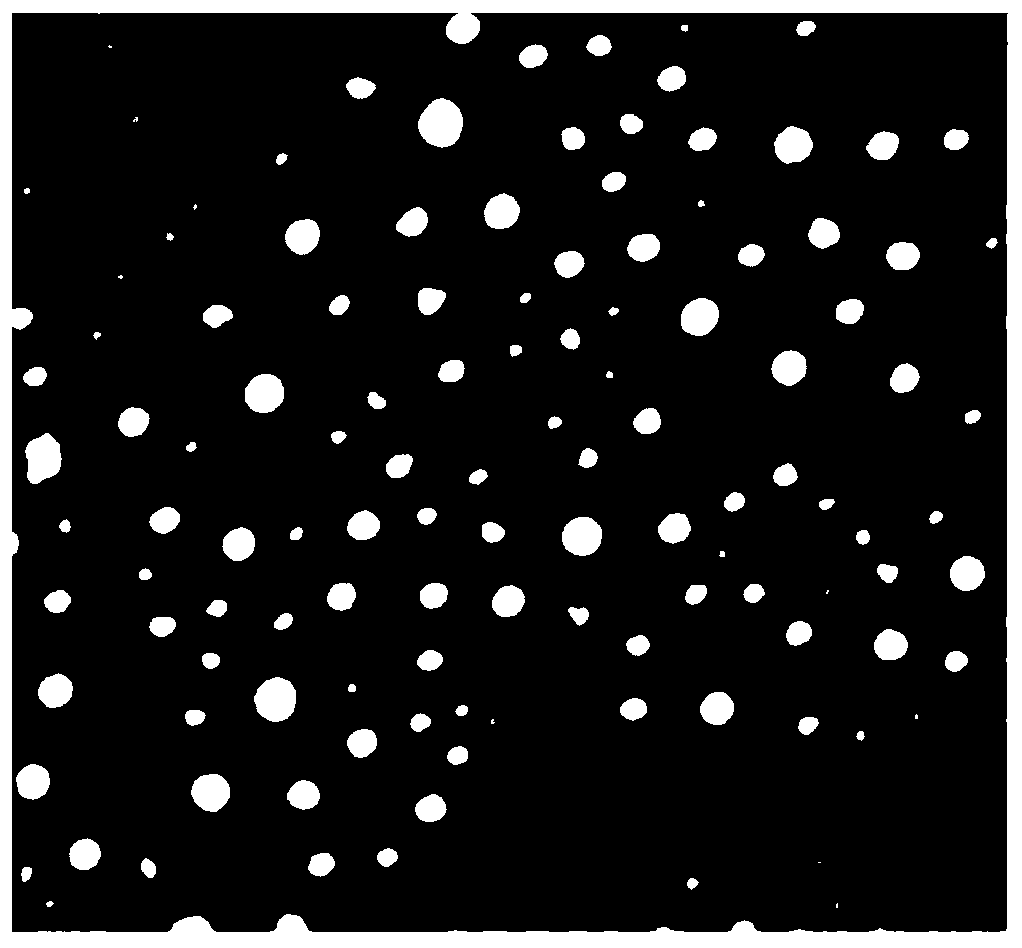

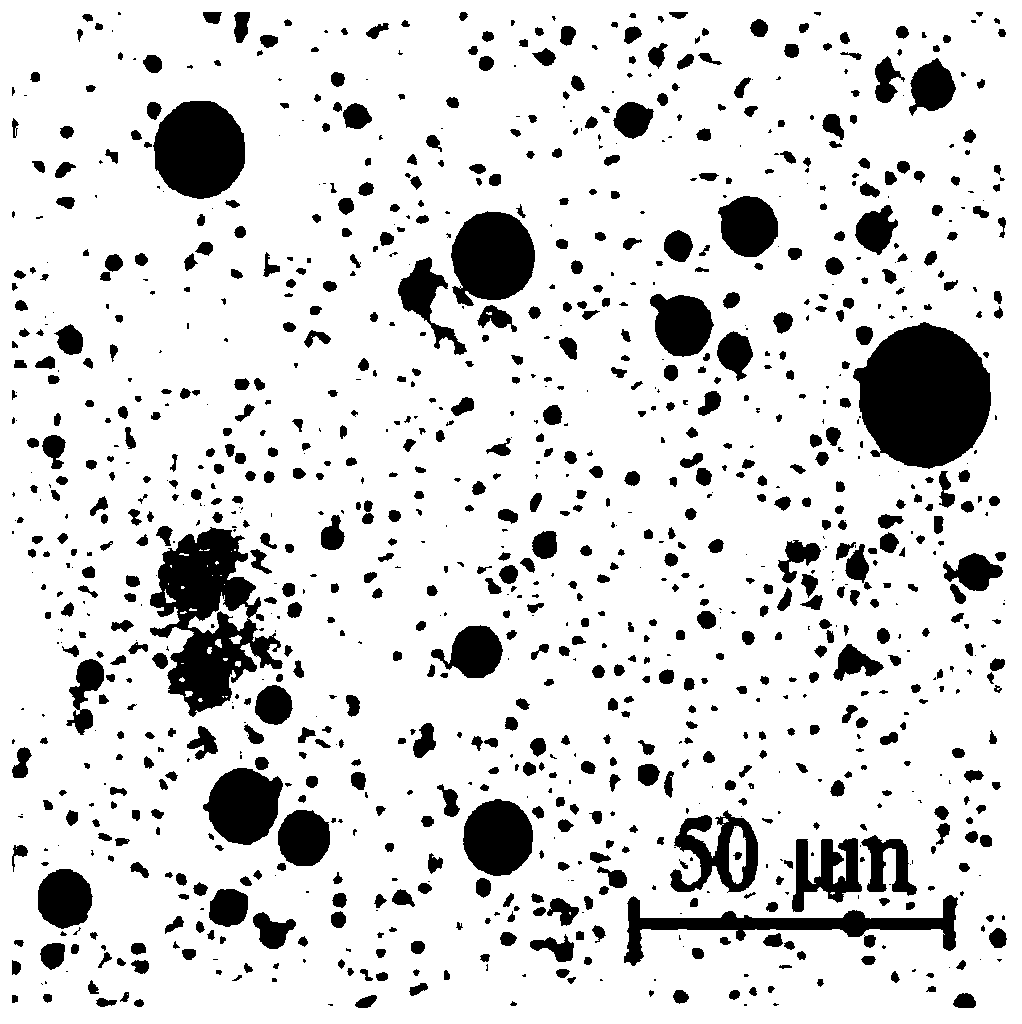

[0047] Example 3 Viscosity of the emulsion formed by the in-situ emulsification viscosity-increasing system and crude oil with controllable viscosity

[0048] The degree of salinity is prepared separately to be 0.5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.01×10 4 mg / L) No. 1#, 3×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.1×10 4 mg / L) No. 2#, 5×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 0.5×10 4 mg / L) No. 3#, 10×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.0×10 4 mg / L) No. 4# and 24×10 4 mg / L (Ca 2+ , Mg 2+ The concentration is 1.5×104 mg / L) No. 5# mineralized water, stirred for 1 hour. Add 0.4% sodium carboxylate petroleum, 0.15% superfine montmorillonite, and 0.05% amylose in 1#; add 0.4% sodium fatty alcohol ether sulfonate, 0.15% super Fine silicon dioxide, 0.05% hydroxymethyl cellulose; Add 0.4% dodecyl hydroxy sultaine, 0.15% superfine iron oxide, and 0.05% sodium alginate in 3#; Add 0.4% alkanolamide, 0.15% superfine titanium dioxide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com