A self-precipitating prestressed anti-slide pipe pile and its construction method

A technology of prestressed pipe piles and construction methods, which is applied in excavation, sheet pile wall, foundation structure engineering, etc. Deterioration and other problems, to achieve the effect of reducing manual work intensity, improving safety and long-term effectiveness, and shortening work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

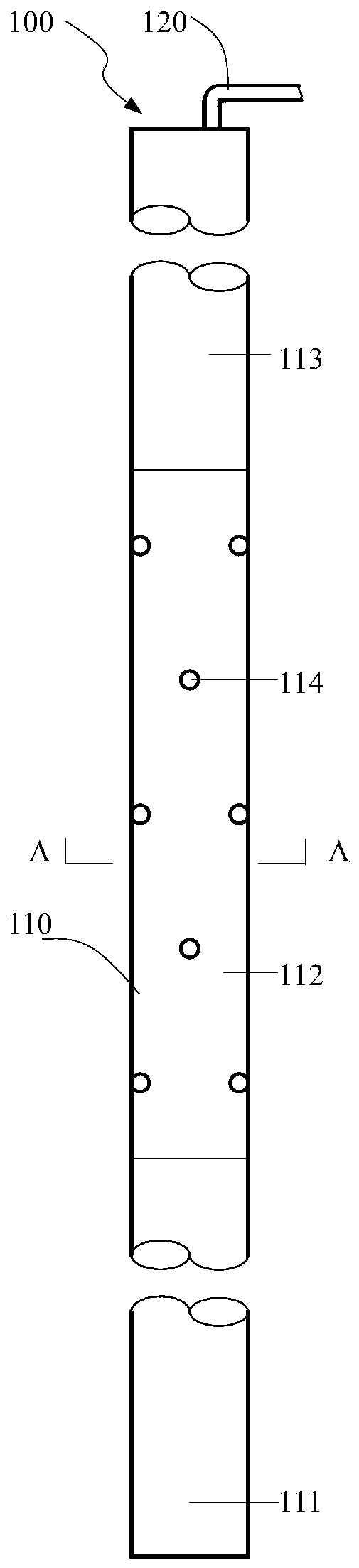

[0042] Such as Figure 1 to Figure 3 As shown, the self-prestressed anti-slide pipe pile 100 provided in this embodiment includes: a prestressed pipe pile 110 and a self-pumping and drainage pipeline 120 .

[0043] The prestressed pipe pile 110 adopts a circular hollow prestressed high-grade prefabricated concrete structure, see image 3 Specifically, it can be prefabricated by making a reinforcement cage through vertical prestressed steel bars 110a and spiral stirrups 110b, and then pouring concrete 110c. The prestressed steel bar 110a is prestressed by the pretensioning method, and the bending moment and shear capacity of the prestressed pipe pile 110 are calculated and determined according to the landslide thrust and earth pressure near the stratum sliding zone, and the spiral stirrup 110b is configured. If necessary, further reinforcing steel bars can be configured.

[0044] see figure 1 , the prestressed pipe pile 110 has an anchor section 111 , a permeable section 112...

Embodiment 2

[0049] Such as Figure 4 with Figure 5 As shown, the self-falling prestressed anti-slide pipe pile 100 provided in this implementation, the parts involved and the position and connection relationship between the parts are the same as those in the first embodiment, the difference is that at the end of the anchoring section 111 There is a picket head 115 at the top, and the picket head 115 can be integrally formed with the prefabrication of the prestressed pipe pile 110, or it can be realized through later installation and fixation.

[0050] The prestressed pipe pile 110 provided in this implementation, because it has a sharp pile head 115, can be directly constructed in the environment of ordinary ground density by adopting the embodiment of static pressing or hammering. The engineering equipment used for striking is all existing equipment and can be used directly. The following construction methods are used for specific construction:

[0051] The first step is to use the ex...

Embodiment 3

[0054] Such as Figure 6 to Figure 10 As shown, the self-falling prestressed anti-slide pipe pile 100 provided in this embodiment, the parts involved and the position and connection relationship between the parts are the same as those in the first embodiment, the difference is that the implementation needs to be checked before use. The prestressed pipe pile 110 provided in Example 1 undergoes further pretreatment to adapt to the embodiment of placing the pile after pre-drilling.

[0055] The pretreatment of pipe piles may include: closing the end of the anchoring section 111, and setting the lower grouting pipe 116, the filter pipe 117 and the upper grouting pipe on the outside of the anchoring section 111, the permeable section 112 and the cantilever section 113 respectively. Pipe 118, etc., its purpose is to facilitate the efficient and quick placement of prestressed pipe piles 110 in the environment of relatively dense ground, and at the same time ensure that the prestresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com