Heat-conducting plastic master batch, preparation method thereof and heat-conducting plastic

A technology of thermally conductive plastics and inorganic thermally conductive fillers, applied in the field of thermally conductive plastics, can solve problems such as difficult cutting, difficult processing, and further research on thermally conductive plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

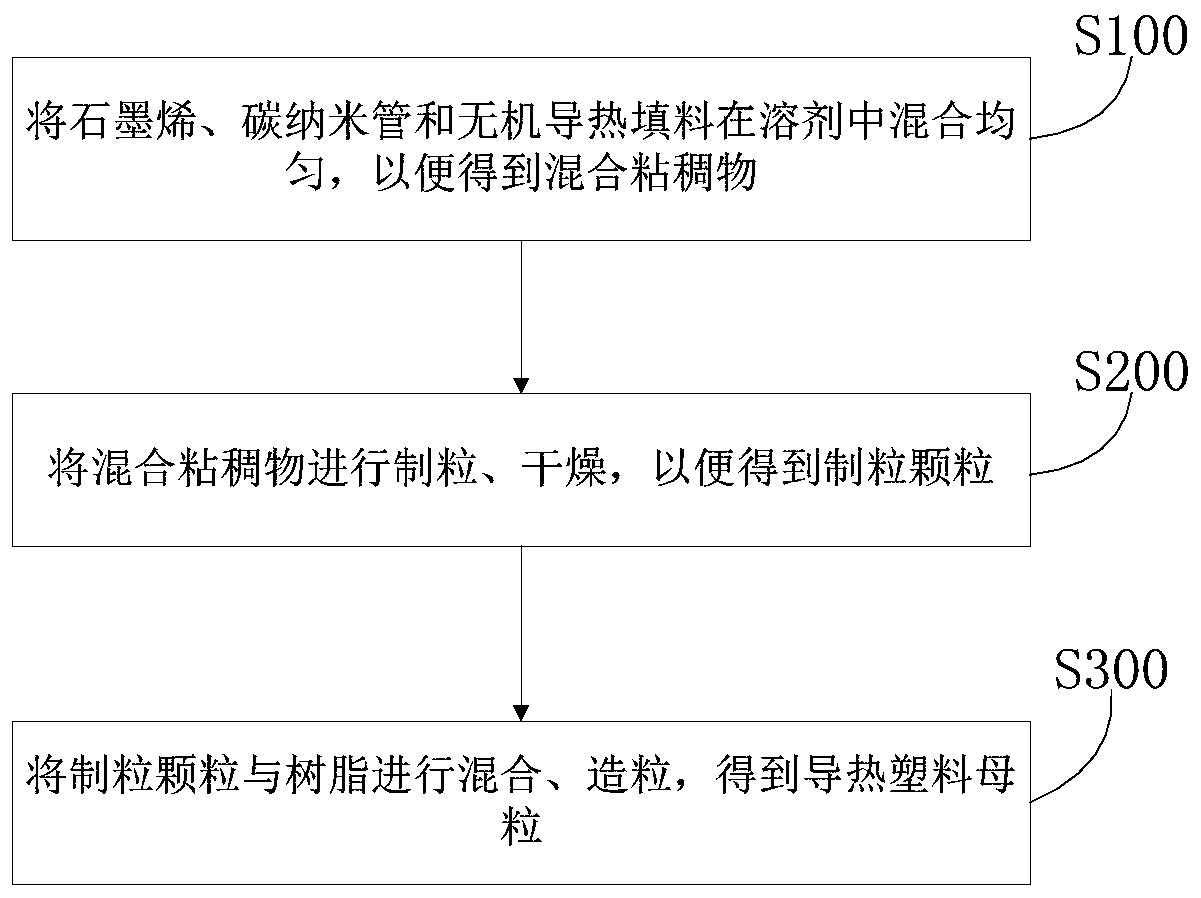

Method used

Image

Examples

Embodiment 1

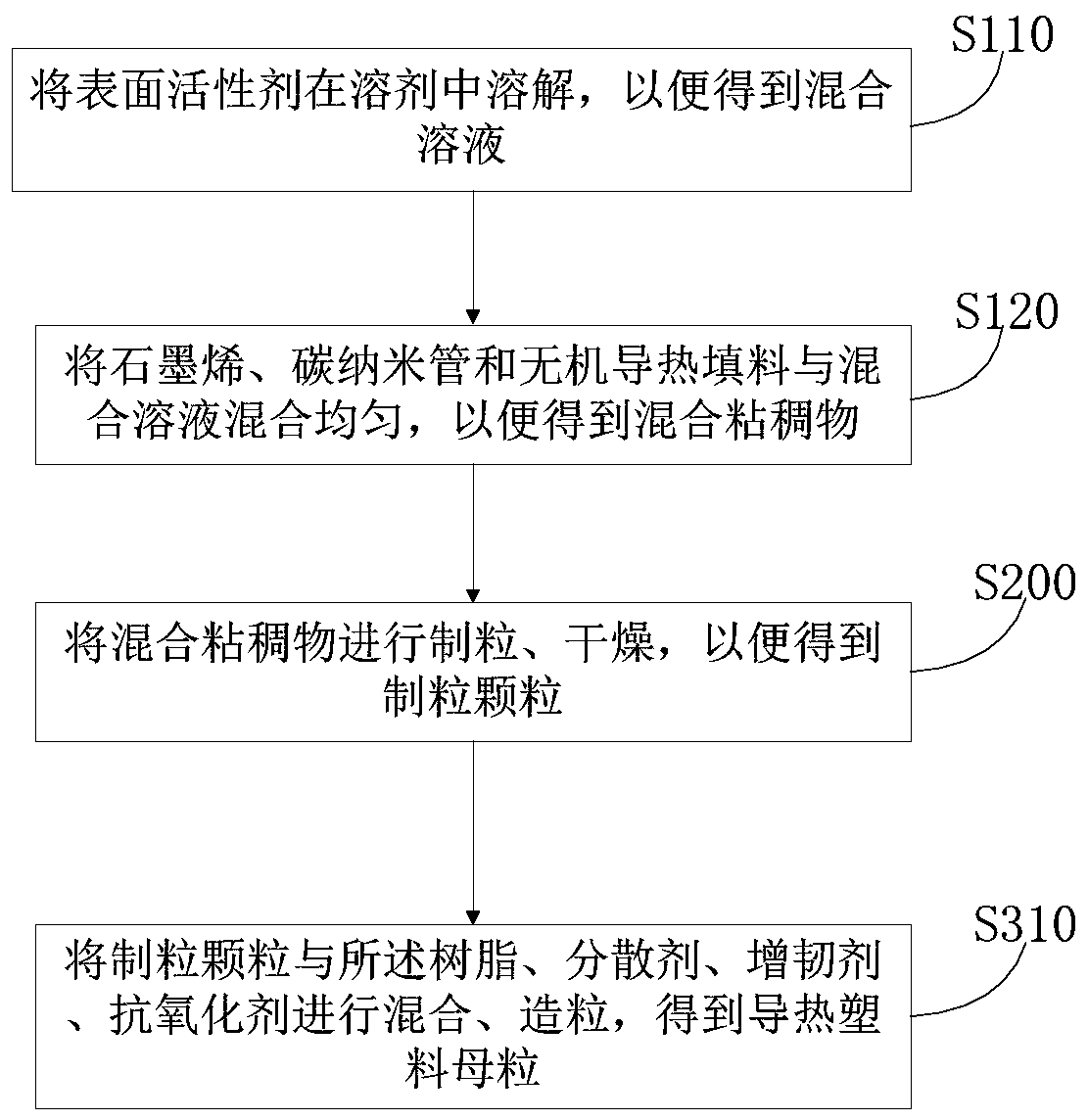

[0058] A micro-nano hybrid high-fill thermally conductive plastic masterbatch and an environmentally friendly preparation method thereof, comprising the following steps:

[0059] S11: Add 5g of polyvinylpyrrolidone (PVP) and 2000g of 50°C ethanol into a container, stir to dissolve the PVP, and obtain a mixed solution;

[0060] S12: Add the mixed solution obtained in 800g graphene nanosheets, 200g arrayed multi-walled carbon nanotubes, 200g alumina and S11 into a horizontal mixer, and mix for 8min (horizontal) at a speed of 800r / min (actual rotating speed). The power of the type mixer is generally 30kW, the maximum rotating speed is 1500r / min, the ratio of the mixing output energy to the mass of the mixed viscous material is 0.67kWh / kg), and the mixed viscous material is obtained;

[0061] S13: Add the mixed viscous material obtained in S12 into a high-speed mixing granulator, extrude it into granules through a screen, and dry in an oven at a temperature of 80°C for 4 hours to ...

Embodiment 2

[0064] A micro-nano hybrid high-fill thermally conductive plastic masterbatch and an environmentally friendly preparation method thereof, comprising the following steps:

[0065] S21: Add 10g sodium carboxymethylcellulose (CMC) and 2000g 50°C pure water into a container, stir to dissolve the CMC, and obtain a mixed solution;

[0066] S22: Add the mixed solution obtained in 200g graphene nanobelts, 100g winding multi-walled carbon nanotubes, 400g magnesium oxide and S21 into a high-speed mixer, and mix for 5min at a speed of 500r / min (the power of the horizontal mixer Generally 30kW, the maximum speed is 1500r / min, the ratio of the output energy of mixing to the mass of the mixed viscous is 0.31kWh / kg), and the mixed viscous is obtained;

[0067] S23: Add the mixed viscous material obtained in S22 to a rotary granulator, extrude it into granules through a screen, and dry in an oven at a temperature of 80°C for 6 hours to obtain granulated granules;

[0068] S24: Mix the granul...

Embodiment 3

[0070] A micro-nano hybrid high-fill thermally conductive plastic masterbatch and an environmentally friendly preparation method thereof, comprising the following steps:

[0071] S31: Add 10g of sodium dodecylbenzenesulfonate (SDBS) and 1000g of 60°C propanol into a container, stir to dissolve the SDBS, and obtain a mixed solution;

[0072] S32: Add 480g of two-dimensional exfoliated graphene, 160g of winding multi-walled carbon nanotubes, 40g of silicon carbide and the mixed solution obtained in S31 into a vertical mixer, and mix for 10min at a speed of 1200r / min (horizontal mixer The power is generally 30kW, the maximum rotating speed is 1500r / min, the ratio of the mixing output energy to the mixed viscous mass is 2.35kWh / kg), and the mixed viscous is obtained;

[0073] S33: Put the mixed viscous material obtained in S32 into a swinging granulator, extrude it into granules through a screen, and dry in an oven at a temperature of 100°C for 4 hours to obtain granulated granule...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com