Single-oil-cylinder drive device

A driving device and a single oil cylinder technology, applied in the field of injection molding machine manufacturing, can solve problems such as the inability to realize screw melting and glue processing, and achieve the effects of ingenious structural design, reduction of production costs, and elimination of cumbersome steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

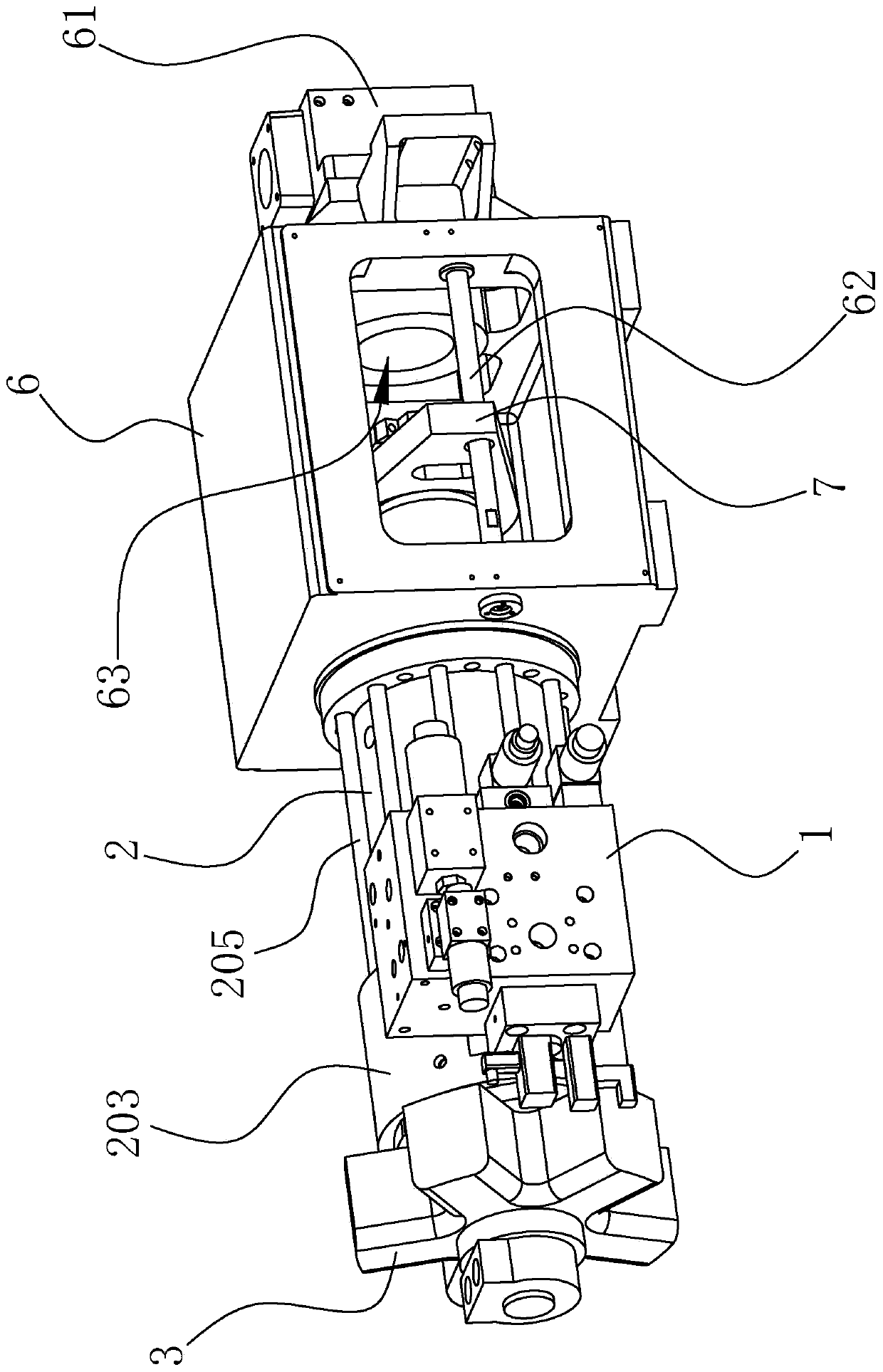

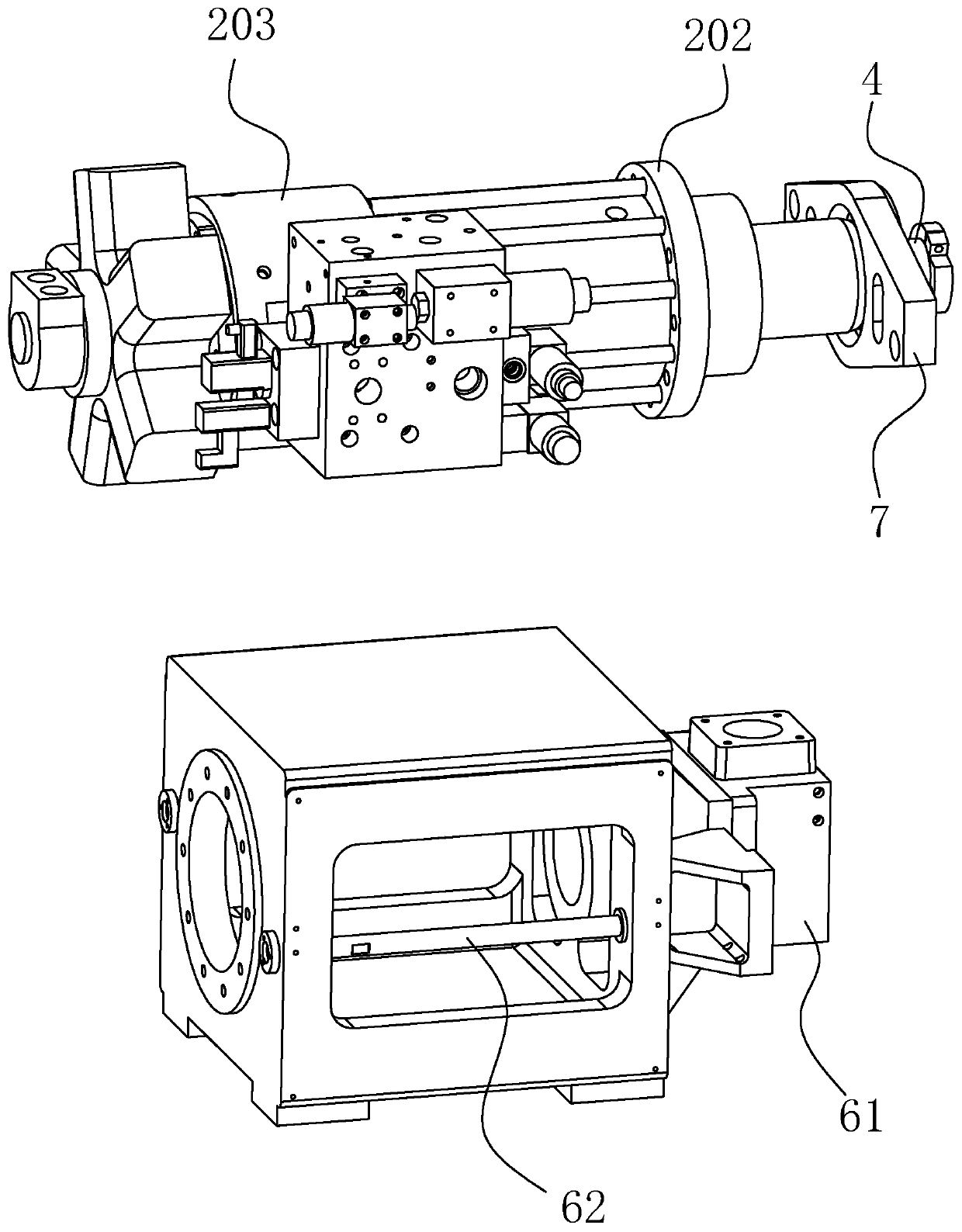

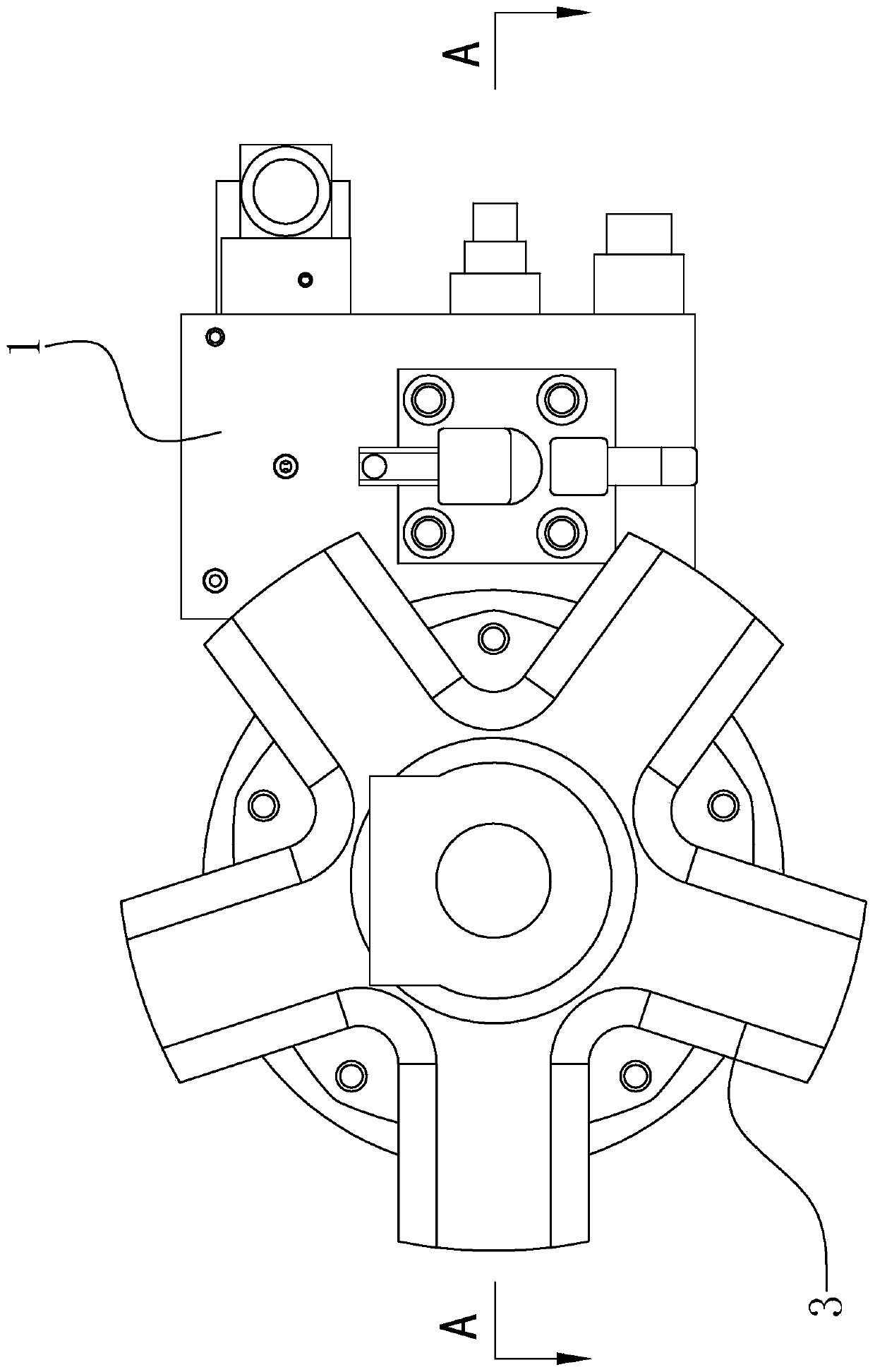

[0035] Such as Figure 1 to Figure 19As shown, the single oil cylinder driving device of this embodiment includes an oil cylinder 2 and an oil cylinder driving module. A transmission seat 4 capable of connecting an injection molding screw is arranged at the end of the piston rod 26 of the oil cylinder 2, and the propulsion chamber 21 of the oil cylinder 2 is connected to the return The retreat chamber 22 communicates with the cylinder drive module through pipelines respectively, and the cylinder drive module is used to change the oil pressure difference between the advance chamber 21 and the retreat chamber 22 to drive the piston rod 26 to advance and retreat. The seal is provided with a rotating mechanism, one end of the rotating mechanism is connected to the piston rod 26 in transmission, and the piston rod 26 can slide back and forth relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com