Broaching tooling for turbine discs and disc parts

A technology for disc parts and turbine discs, which is applied in the field of CNC machine tools, can solve the problems of poor quality assurance, low machining accuracy, and cumbersome machining process, and achieves simple broaching process, high machining accuracy, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

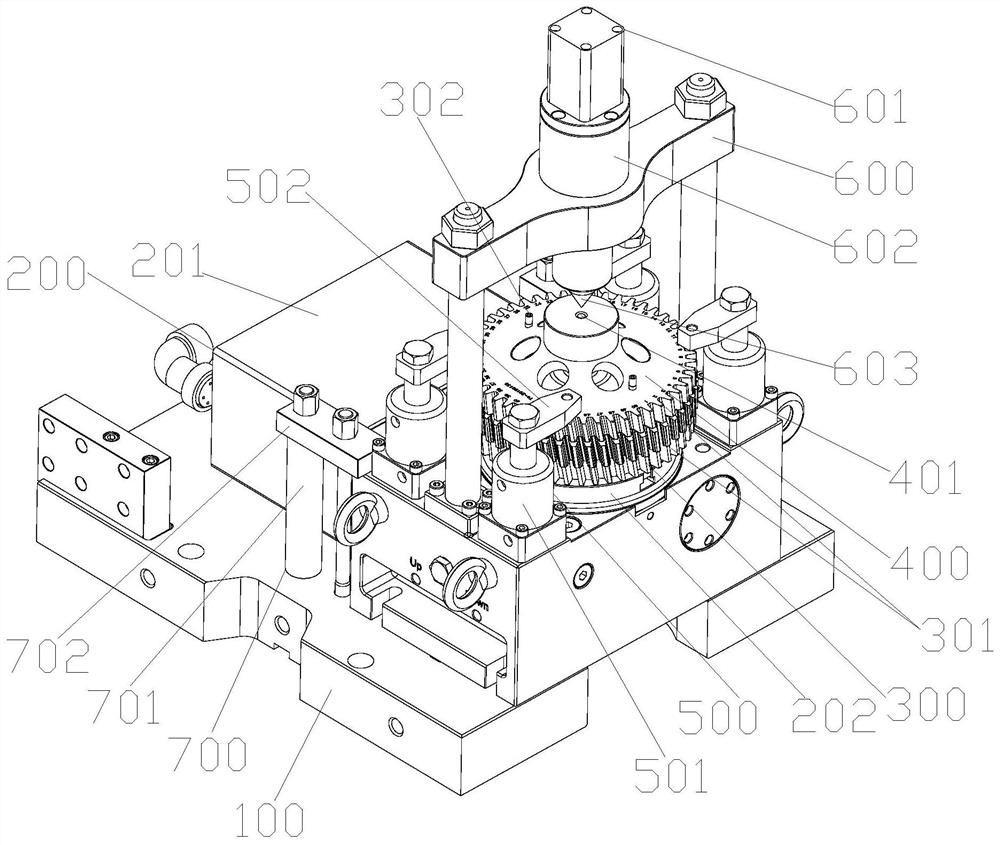

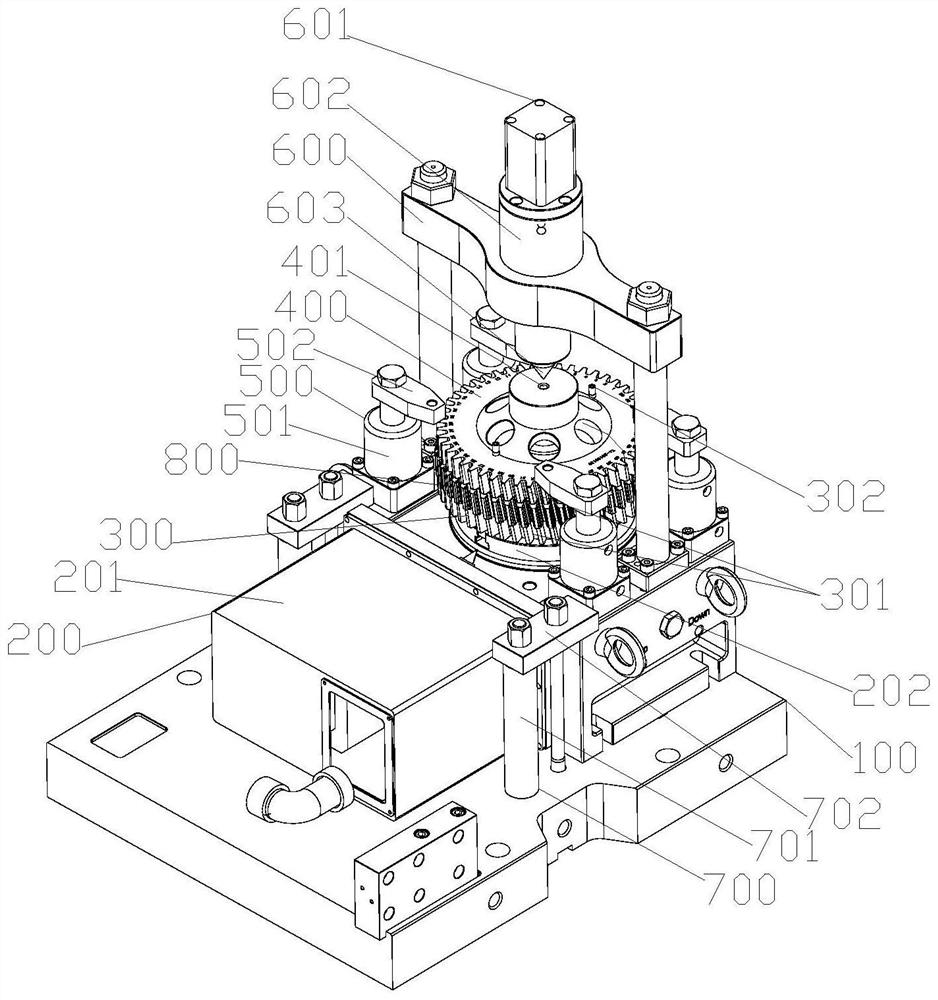

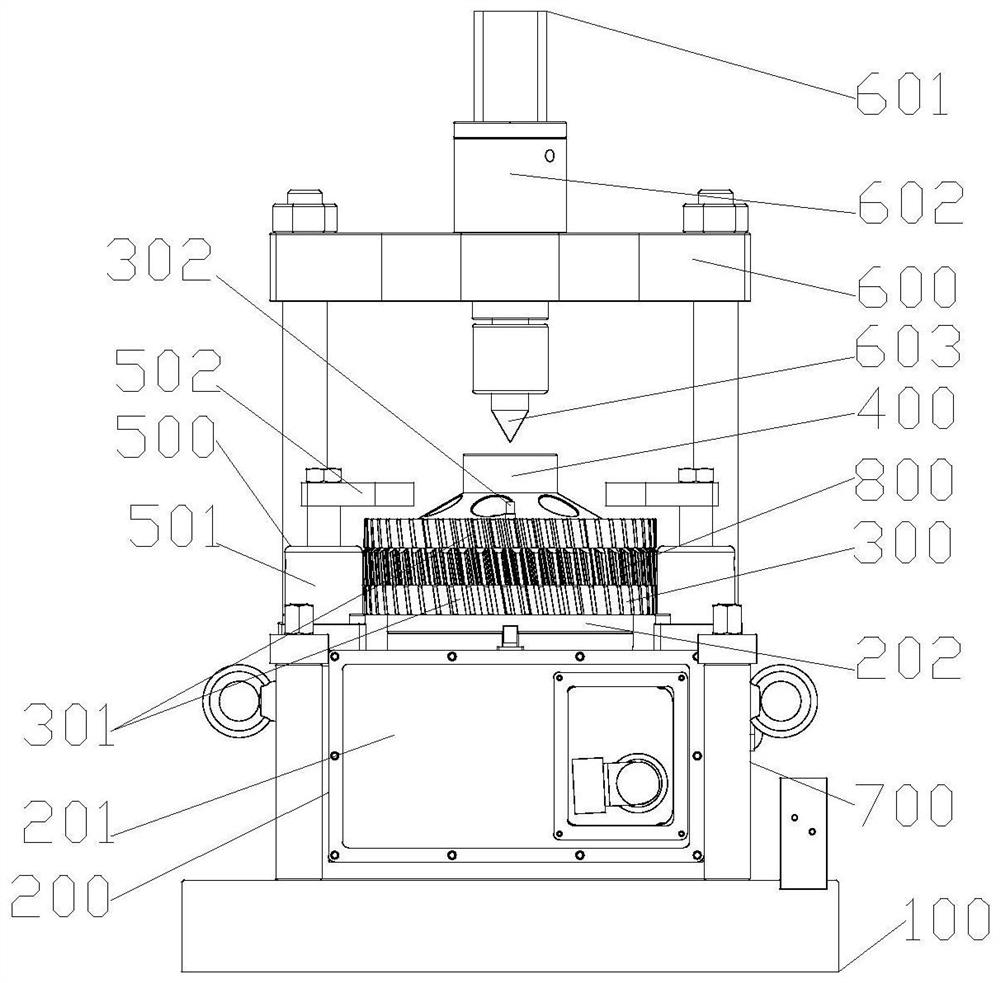

[0033] Such as figure 1 with figure 2 The shown broaching tooling for turbine discs and disc parts includes a mounting seat 100, and the mounting seat is provided with such image 3 The index plate 200 shown, the index plate is as Figure 8 The shown turntable 202 is provided with such as Figure 4 The shown support plate 300 is detachably connected on the support plate as Figure 5 As shown in the gland plate 400, the housing 201 of the index plate is provided with one or more such as Image 6 In the first hydraulic clamping device 500 shown, the free clamping end of the first hydraulic clamping device corresponds to the outer disc surface of the gland disc. The shell of the index plate is equipped with such as Figure 7 As shown in the supporting frame 600, a second hydraulic clamping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com