Manufacturing method of flexible substrate and flexible packaging structure

A flexible substrate and manufacturing method technology, which is applied in the manufacture of semiconductor/solid-state devices, printed circuits connected with non-printed electrical components, electrical components, etc. It can well meet the requirements of system integration and the difficulty of process control, so as to reduce the risk of line interconnection breakage, improve the reliability of fixing, and facilitate the overall packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

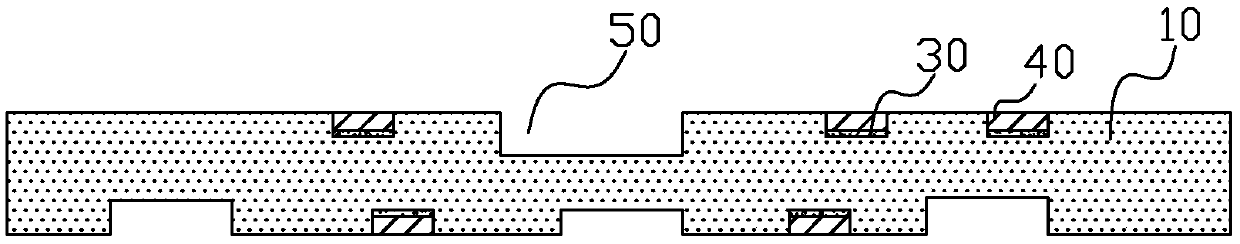

[0033] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the detailed description is as follows in conjunction with the accompanying drawings and preferred embodiments.

[0034] The invention provides a method for manufacturing a flexible substrate and a flexible packaging structure with the flexible substrate. The flexible substrate can better meet the requirements of the flexible packaging structure for the flexible substrate, and at the same time can control the layout of the connecting lines more accurately.

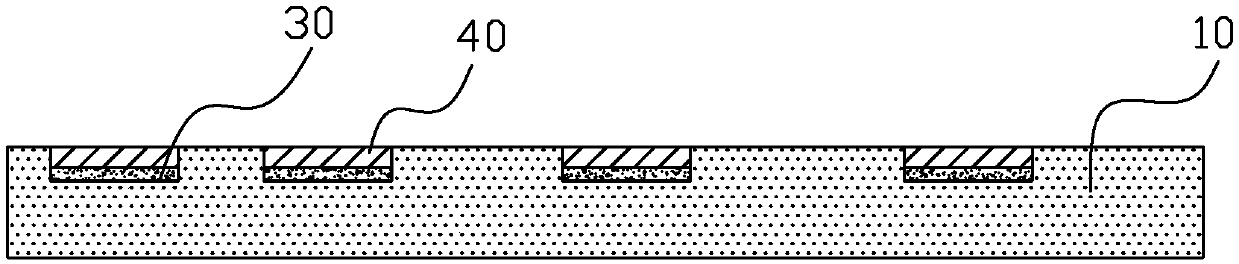

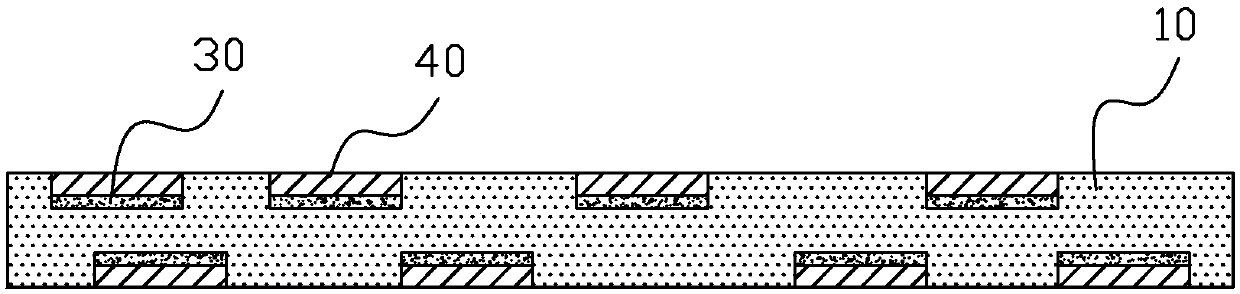

[0035] figure 1 The cross-sectional structure intention of the flexible substrate provided for the first embodiment of the present invention, such as figure 1 As shown, the flexible substrate provided by the first embodiment of the present invention includes a flexible substrate 10, and a first groove 20 is formed on the flexible substrate 10 (see Figure 6B ), the connecting ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com