Online measuring device for size and morphology of particle

A measuring device and morphology technology, which is applied in the field of on-line measuring devices for particle size and specific morphology, can solve the problems of lack of universality and limited scope of application, and achieve the effect of avoiding easy pollution and enriching reference information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Lithium-ion battery cathode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 On-line particle size measurement for continuous production processes.

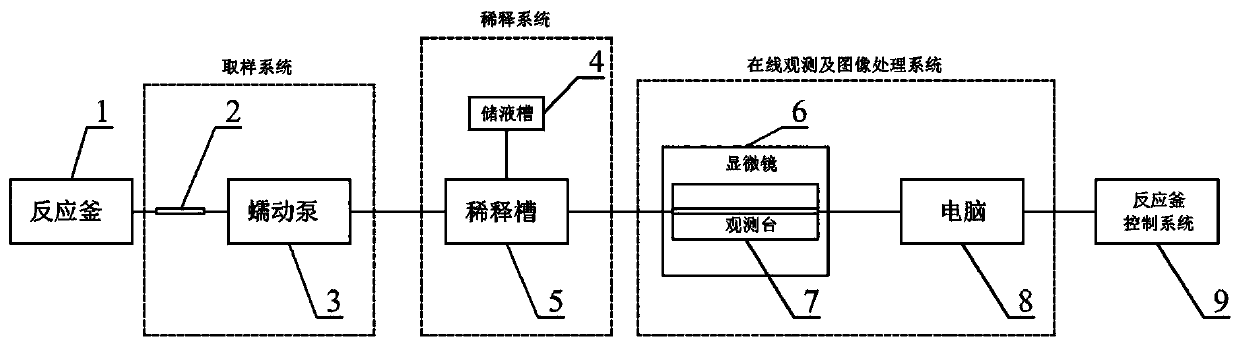

[0020] like figure 1 As shown, an on-line measurement device for particle size and morphology, including a reactor 1, is used to produce the precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 The product, the product is transported to the dilution system through the retrieving system. The retrieving system is composed of a retrieving pipe 2 and a peristaltic pump 3. The dilution system is composed of a water tank 4 and a dilution tank 5. One end of the retrieving pipe 2 is connected to the reactor 1. Under the action of the peristaltic pump 3, the sample is transported to the dilution tank 5 at the other end, and an appropriate amount of diluent is added from the storage tank 4 according to the concentration of the sample to dilute the sample to a concentration suitable for observation by the observation system. The observation sy...

Embodiment 2

[0022] On-line measurement of crystal size during drug crystallization.

[0023] The level of drug crystallization technology will directly affect important indicators such as crystal size, purity, and crystal form. These indicators will also have an important impact on the safety and efficacy of drugs. Therefore, it is necessary to be able to grasp these indicators in real time to adjust the production process at any time to improve products. Purity, crystal form purity, uniform particle size distribution and bulk density, etc.

[0024] like figure 1 As shown, an on-line measurement device for particle size and shape, including a reactor 1, is used for the drug crystallization process, and the product is transported to the dilution system through a feeding system, which consists of a feeding pipe 2 and a peristaltic pump 3 , the dilution system is composed of a liquid storage tank 4 and a dilution tank 5. One end of the feeding pipe 2 is connected to the reaction kettle 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com