Device and method for detecting orientation of link unit of sleeve chain

A detection device and sleeve technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of inability to distinguish the shape orientation of the inner chain of the opposite sex, low accuracy and reliability of manual inspection, and production problems. Problems such as high scrap rate, achieve the effect of reducing the inspection intensity of finished products, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

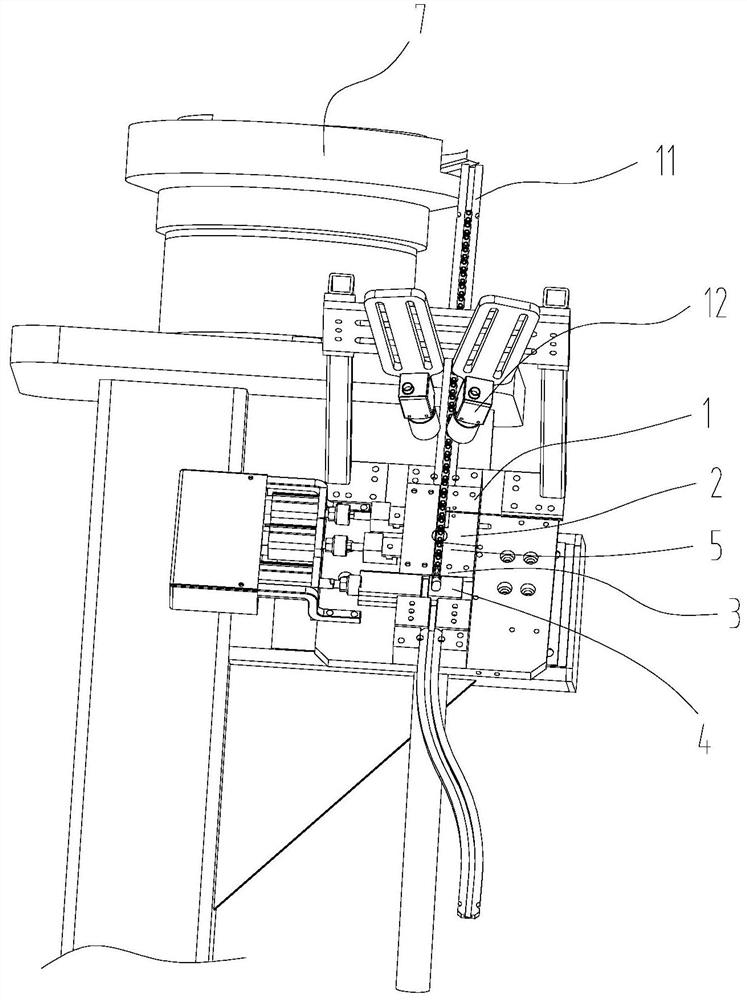

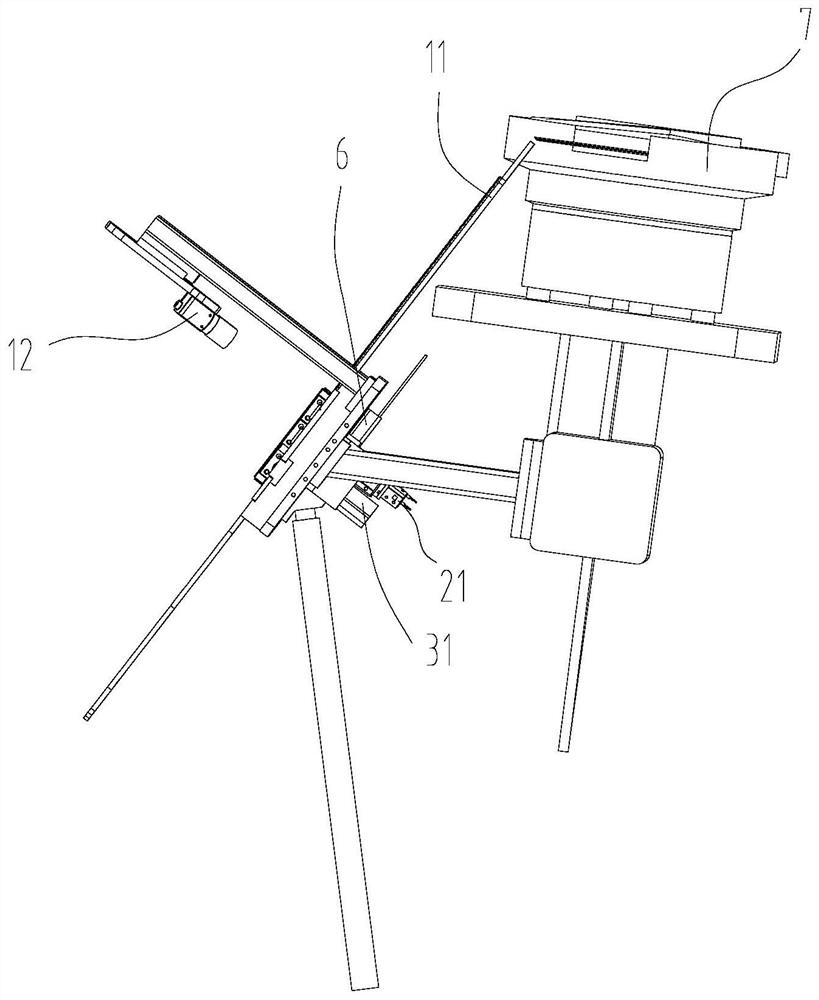

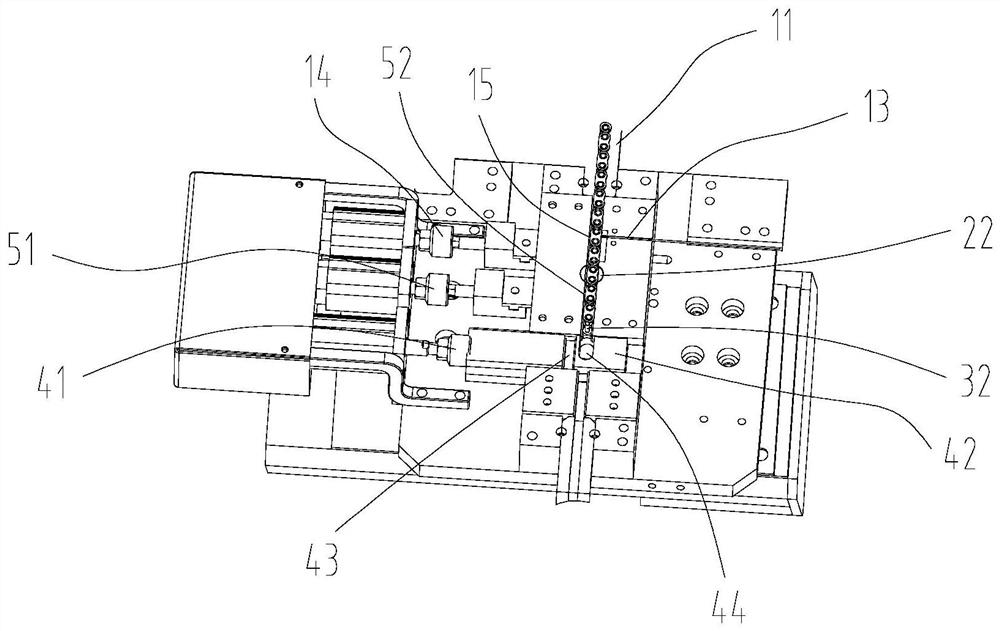

[0029] Such as figure 1 As shown, the link unit is added to the vibrating plate 7, and the link unit enters the transfer guide rail 11 through the vibration of the vibrating disk 7, since the vibrating disk 7 is located at most at the maximum transfer guide rail 11, and the link unit is gravity Next, slide down from a ramp-type conveying guide rail 11. First enter the detection station 1, after the photoelectric sensor 13 is located, the photoelectric sensor 13 inducts and indicates the action of the first cylinder 14, which is pushed by the chuck 15 connected to the first cylinder 14, and the clip 15 is shifted to the transfer guide rail. 11 in the 11th unit, such as figure 2 As shown, under the light source 6 below the chuck 15, the camera 12 can take a photo inside the sleeve 8 of the cartriated link unit, and the two camera 12 is imaged inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com