A kind of sludge clean incineration heat exchange method

A thermal method and sludge technology, applied in combustion methods, incinerators, combustion types, etc., can solve the problems of large power consumption of equipment, waste of bed materials, and high operating costs, reduce nitrogen oxide content, reduce NOx, and achieve The effect of smokeless emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

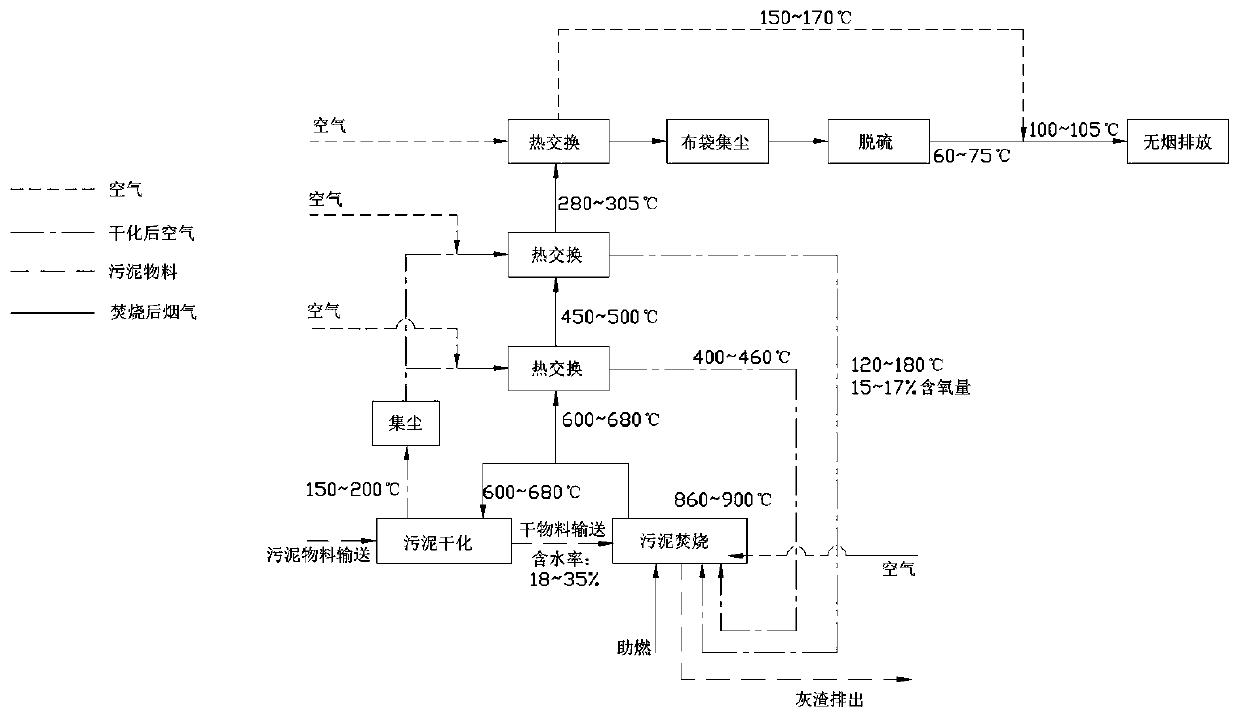

[0027] Such as figure 1 In the shown embodiment, a kind of sludge cleaning incineration heat exchange method comprises the following steps:

[0028] a. Initially, the sludge has a high water content and is difficult to incinerate. Firstly, the sludge with a water content above 55% is dried to reduce the water content of the sludge to 18%~35%.

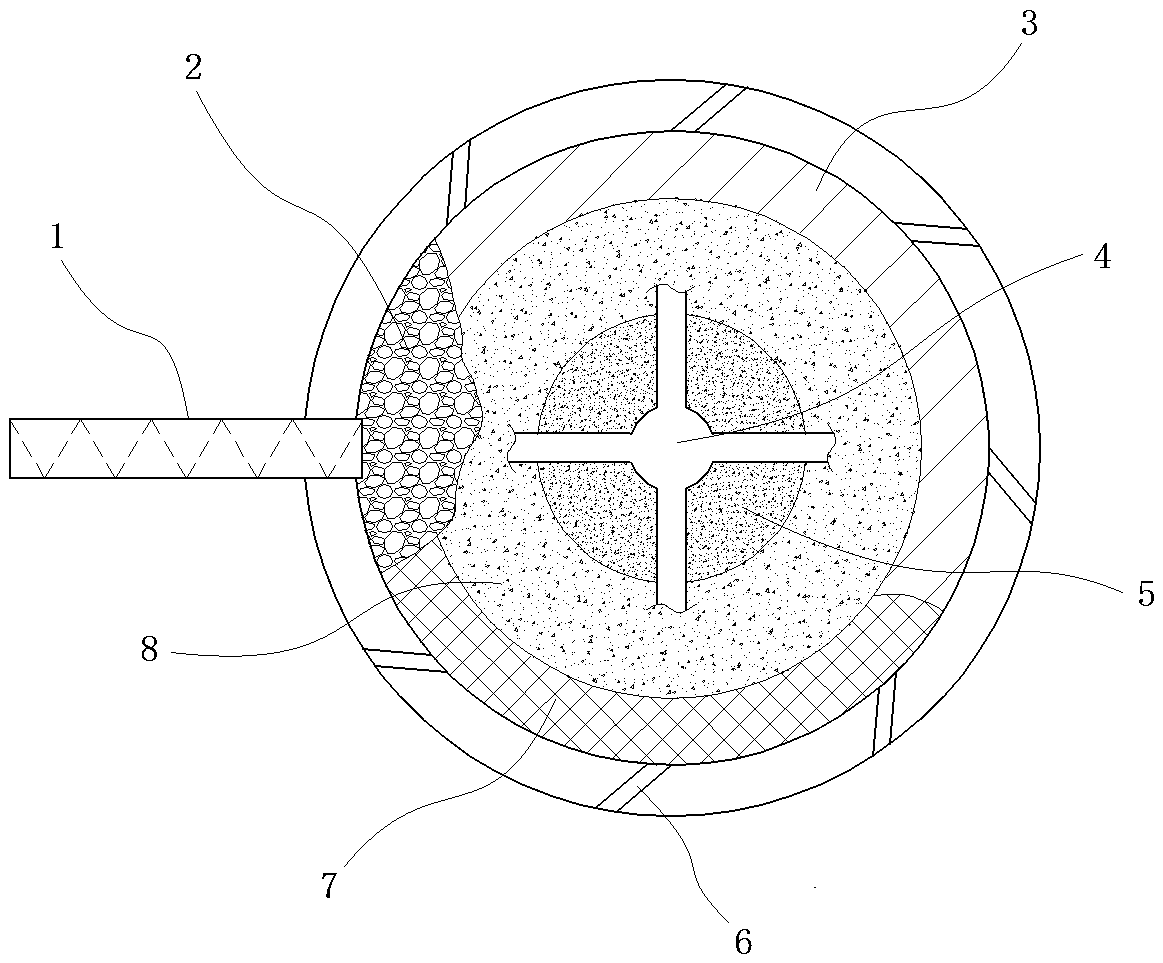

[0029] b. If figure 2 As shown, the sludge can be transported to the incineration area through the screw 1. The incineration area is equipped with a stirring arm 4, which rotates and stirs with the vertical direction as the axis. The incineration area is divided into five areas: dry area 2, large flame area 3, and small flame area. Area 7, charcoal-like combustion area 8 and ash area 5, the sludge enters the drying area 2 from the edge of the incineration area first, the temperature of the sludge rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com