A three-stage throttling throttle valve

A technology of throttle valves and throttle parts, which is applied in the direction of valve lifts, valve details, valve devices, etc., can solve the problems of not being able to guarantee the long-term normal operation of shale gas production and transportation, and reduce the internal flow rate, etc., so as to reduce the gas flow rate, reduce the Effect of small erosion damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

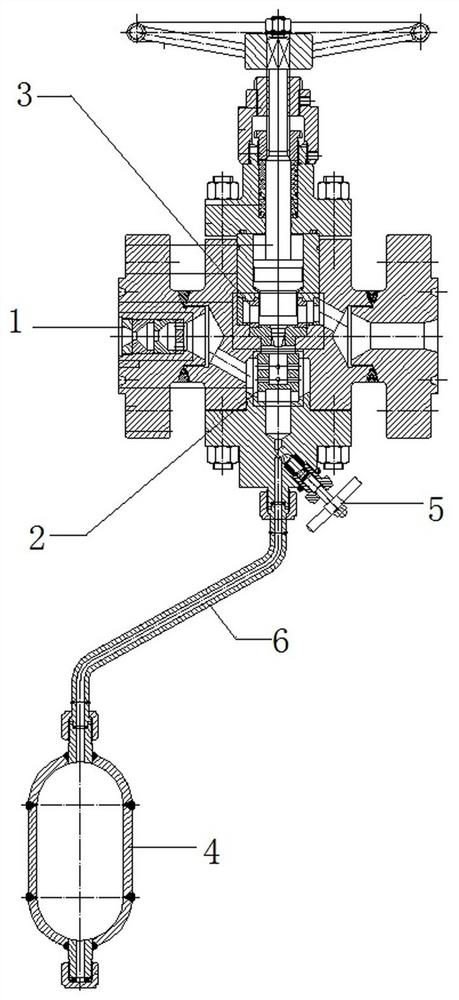

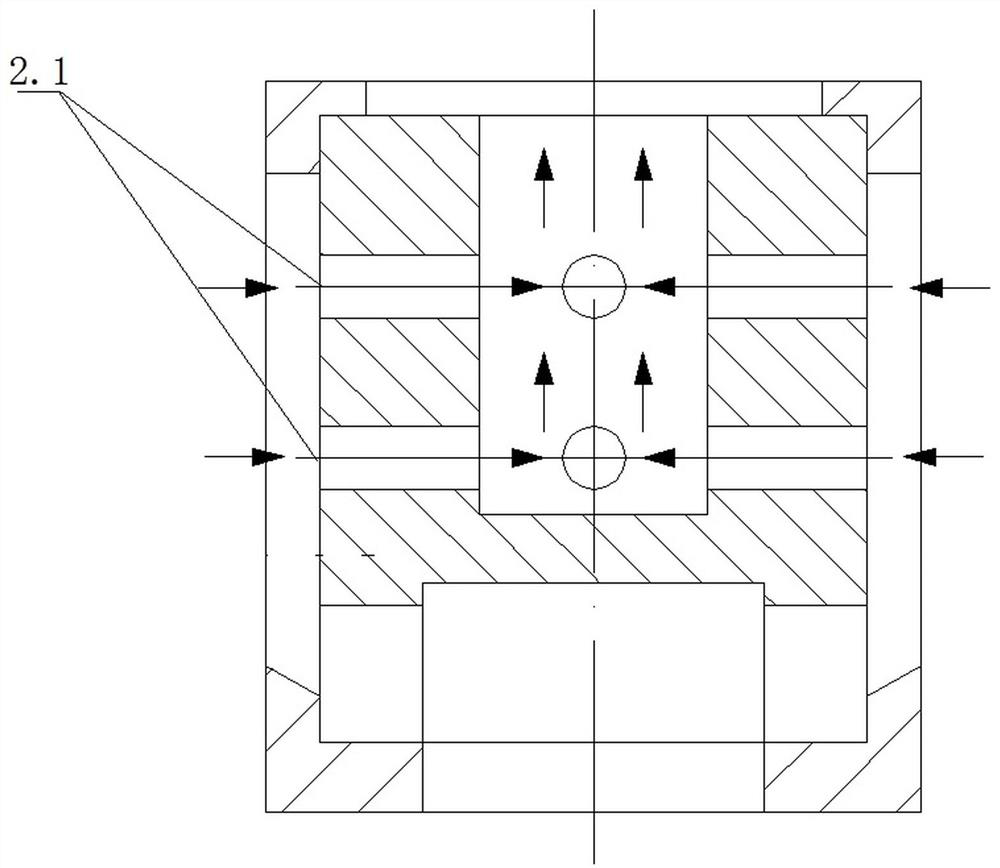

[0026] As a most basic embodiment of the present invention, such as figure 1, a three-stage throttling throttle valve disclosed in this embodiment, includes a valve body with a pressure inlet and a pressure outlet, and in the valve body, between the pressure inlet and the pressure outlet, there is a valve core 3.2 The channel port that controls the opening and closing is connected; the produced gas enters the valve body from the pressure inlet port and passes out from the pressure outlet port through the channel port, and the produced gas enters at a low level and exits at a high level between the pressure inlet port and the pressure outlet port; The outlet of the pressure inlet is provided with a throttling piece I1 for throttling and reducing pressure; the passage port is provided with a throttling piece II2 for removing impurities in the produced gas through hedging; Pressure protection valve core 3.2 throttling piece III3. Throttle piece Ⅰ1, throttle piece Ⅱ2, and throttl...

Embodiment 2

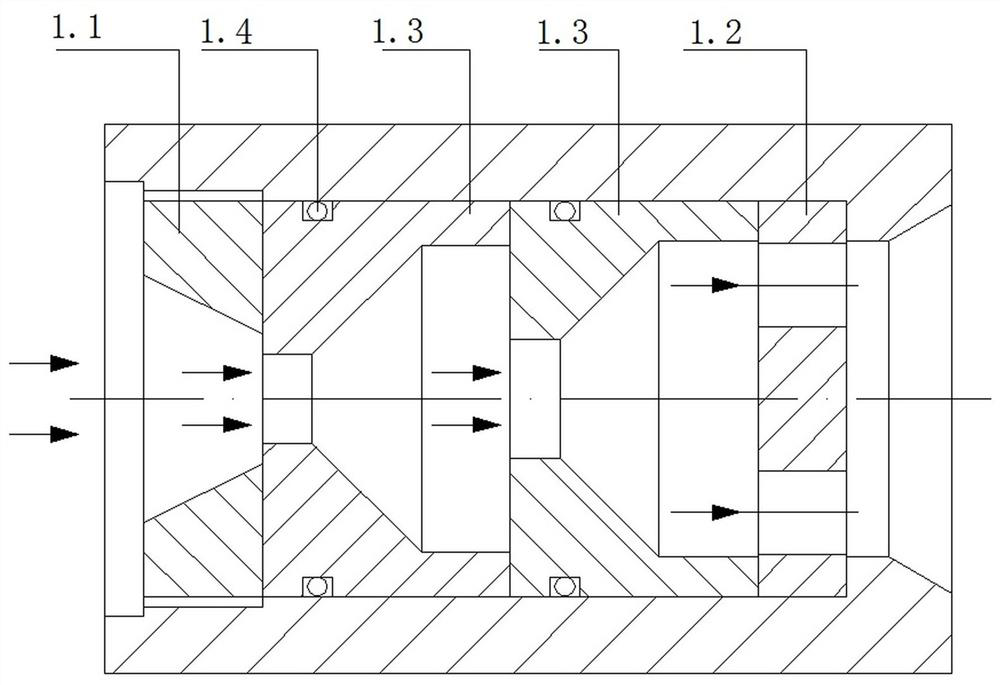

[0029] As a preferred embodiment of the present invention, on the basis of the above-mentioned Example 1, further, as figure 2 As shown, the throttling piece I1 includes several pressure-reducing plates 1.3 arranged between the pressure ring 1.1 at the inlet end and the baffle plate 1.2 at the outlet end in the pressure inlet. The perforated plate with the opening diameter of the outlet port, the baffle plate 1.2 is an orifice plate with several openings smaller than the opening diameter of the outlet port of the orifice plate, the openings of the pressure ring 1.1, the orifice plate and the baffle plate 1.2 form a The throttling and pressure-reducing channel through which the produced gas passes; pressure ring 1.1, pressure-reducing plate 1.3, and baffle plate 1.2 are sequentially transferred from the inner hole of the flange to the pressure-inlet channel, and finally tightened by pressure ring 1.1, and the pressure-reducing plate 1.3 is the inlet The diameter of the port op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com