Production method for improving surface quality of high-grade pipeline steel

A technology of surface quality and production method, which is applied in the production field of improving the surface quality of high-grade pipeline steel. It can solve the problems of large deformation of the steel plate surface, affecting the use, corrosion of the steel plate, etc., and achieve the effect of improving the surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

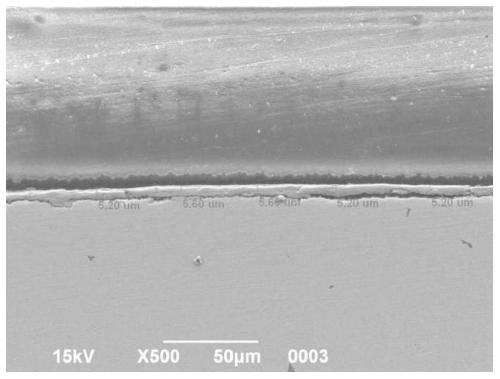

Image

Examples

Embodiment 1

[0056] This embodiment provides a production method for improving the surface quality of high-grade pipeline steel. The steel grade is X70M grade, and the blank is 260mm*2570mm section blank, and the product specification is 22mm*4830mm. Specifically:

[0057] S1, its chemical composition and mass percentage are as follows: C: 0.040%~0.070%, Si: 0.20%~0.30%, Mn: 1.60%~1.80%, P≤0.014%, S≤0.0030%, Ni: 0.10%~0.20 %, Cr: 0.20%~0.30%, Cu≤0.03%, Nb: 0.040%~0.060%, Mo≤0.005%, V≤0.003%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001% ~0.003%, Al: 0.010%~0.050%, the balance is Fe and unavoidable impurities;

[0058] S2. The desulfurization station uses lime and magnesium powder for compound desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.008% after the converter;

[0059] S3. Steelmaking adopts the process route of BOF → LF furnace refining → RH refining → continuous casting. The tapping temperature of the converter is 1668°C, and the tapp...

Embodiment 2

[0067] This embodiment provides a production method for improving the surface quality of high-grade pipeline steel. The steel grade is X90M grade, and the blank is 220mm*1900mm section blank, and the product specification is 16mm*2830mm. Specifically:

[0068] S1, its chemical composition and mass percentage are as follows: C: 0.050%~0.080%, Si: 0.10%~0.20%, Mn: 1.50%~1.70%, P≤0.015%, S≤0.0030%, Ni: 0.10%~0.30 %, Cr: 0.10%~0.20%, Cu≤0.20%, Nb: 0.050%~0.070%, Mo≤0.15%, V≤0.01%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001% ~0.003%, Al: 0.010%~0.050%, the balance is Fe and unavoidable impurities;

[0069] S2. The desulfurization station uses lime and magnesium powder for compound desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.009% after the converter;

[0070] S3. Steelmaking adopts the process route of BOF → LF furnace refining → RH refining → continuous casting. The tapping temperature of the converter is 1648°C, and the tappin...

Embodiment 3

[0078] This embodiment provides a production method for improving the surface quality of high-grade pipeline steel. The steel grade is X80M grade, and the blank is 320mm*2700mm section blank, and the product specification is 30mm*4310mm. Specifically:

[0079]S1, its chemical composition and mass percentage are as follows: C: 0.040%~0.070%, Si: 0.10%~0.30%, Mn: 1.60%~1.90%, P≤0.015%, S≤0.0030%, Ni: 0.15%~0.30 %, Cr: 0.10%~0.20%, Cu≤0.20%, Nb: 0.040%~0.060%, Mo≤0.15%, V≤0.01%, Ti: 0.005%~0.02%, N≤0.0050%, Ca: 0.001% ~0.003%, Al: 0.010%~0.050%, the balance is Fe and unavoidable impurities;

[0080] S2. The desulfurization station uses lime and magnesium powder for composite desulfurization. After desulfurization, the slag is cleaned. S: 0.0020% in the molten iron, and S: 0.006% after the converter;

[0081] S3. Steelmaking adopts the process route of BOF→LF furnace refining→RH refining→continuous casting. The tapping temperature of the converter is 1679°C, and the tapping adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com