Smelting system for iron-based multi-metal mineral materials

A multi-metal and metal ore technology, applied in the field of metal smelting, can solve the problems of poor adaptability of raw materials and high energy consumption, and achieve the effect of improving environmental emission indicators, improving recovery rate, and reducing comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

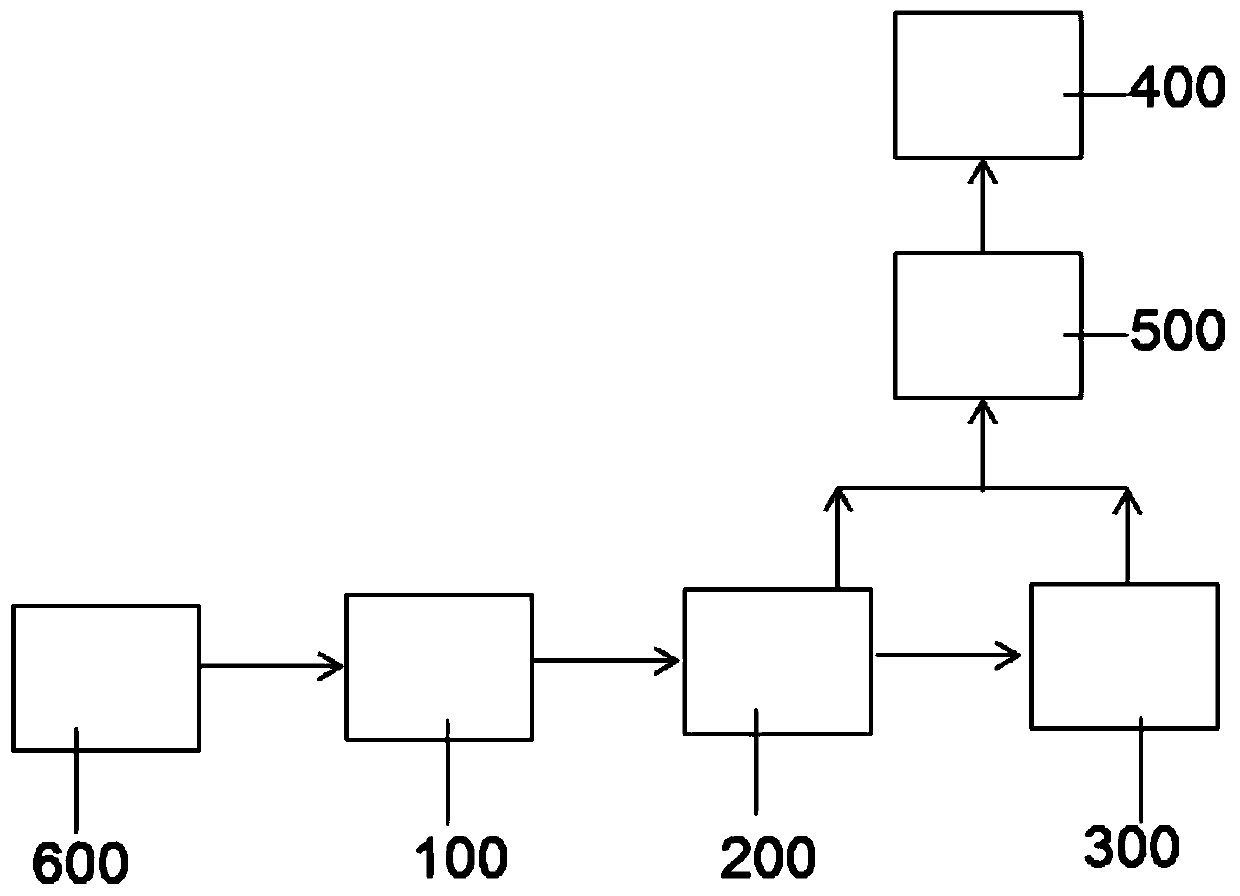

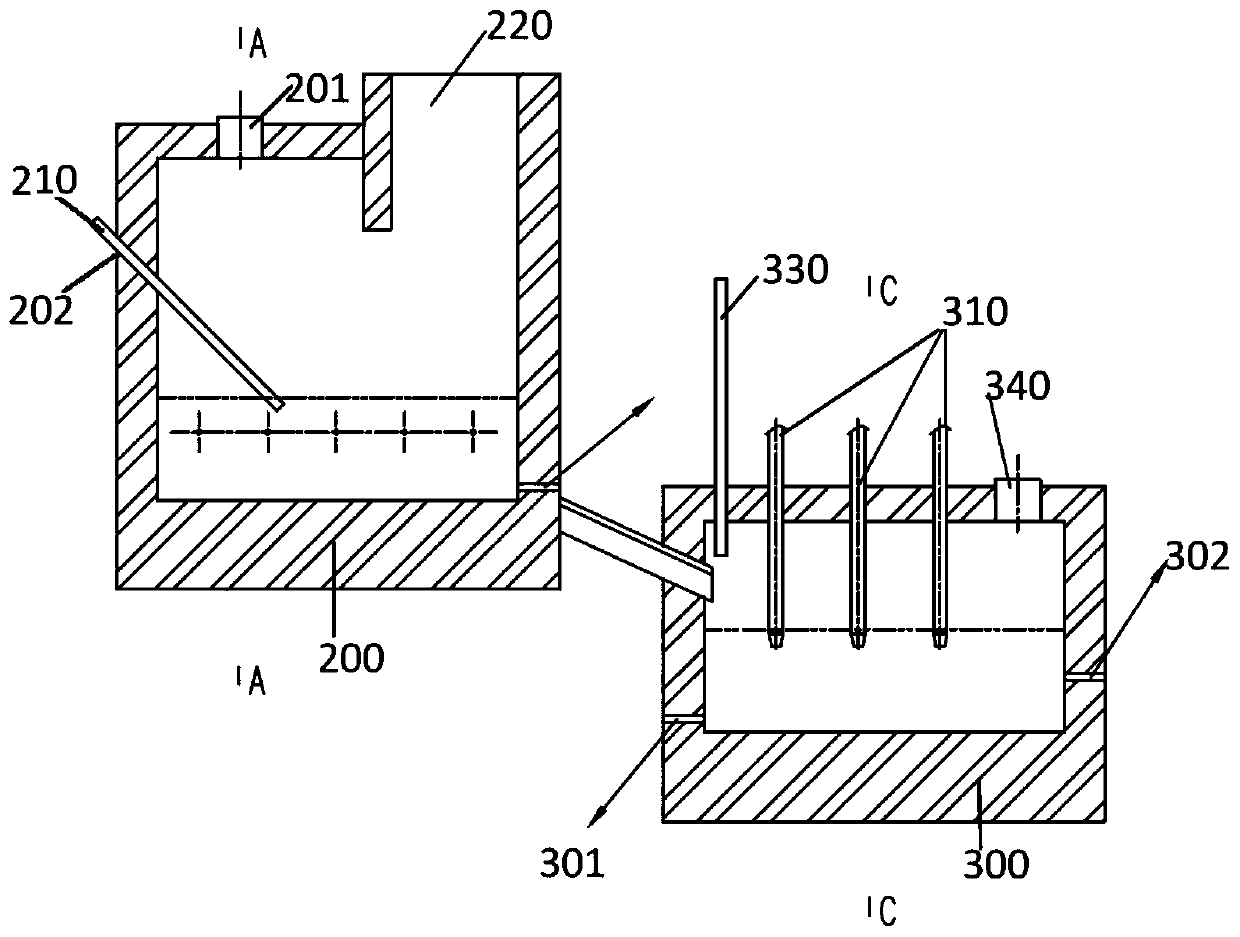

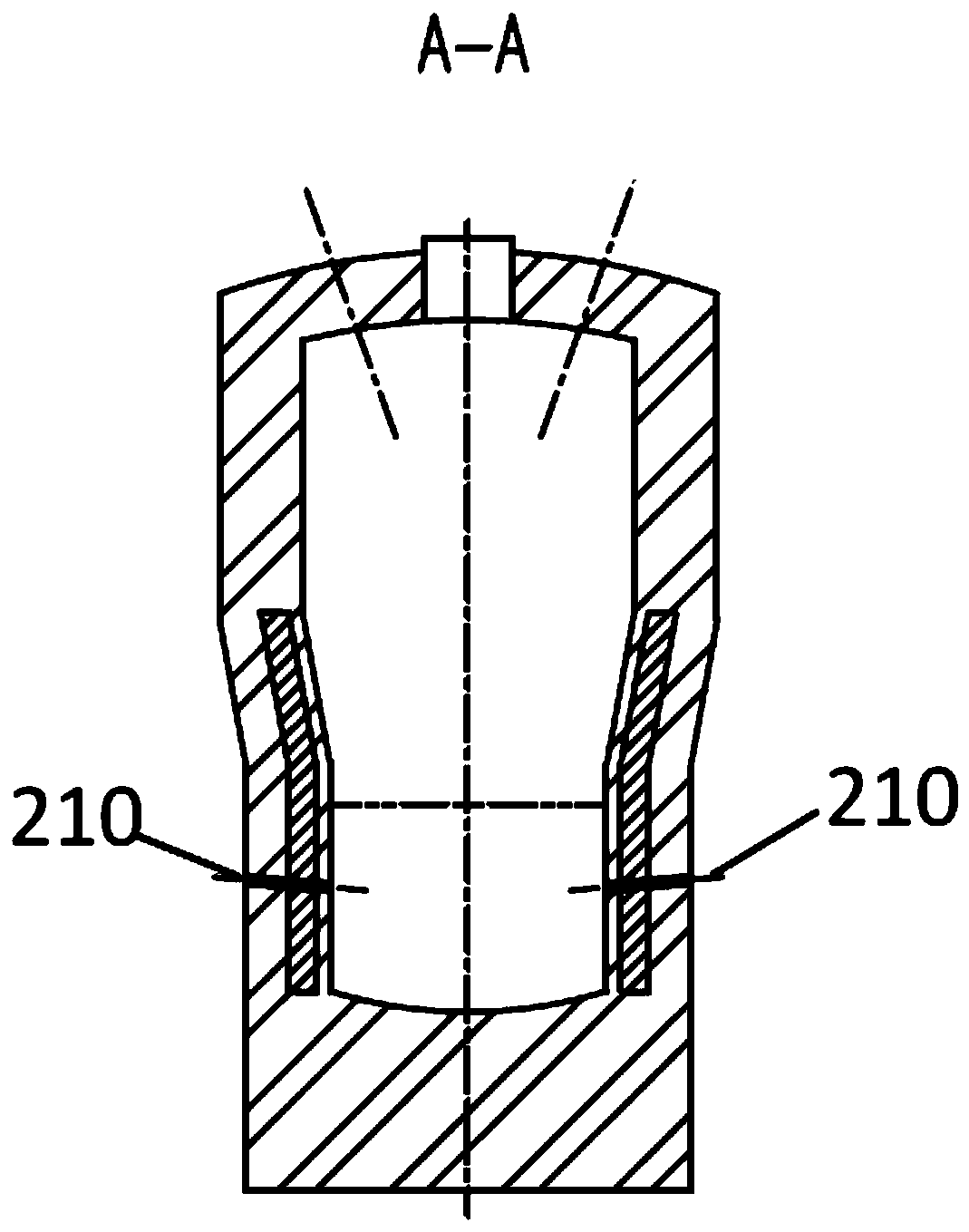

[0040] Such as Figures 1 to 4 As shown, the molten pool smelting device includes a connected molten pool smelting device 200 and an electrothermal reduction device 300. The molten pool smelting device 200 is provided with a first feed port 201 and a second feed port 202, and the first feed port 201 is arranged at the melting point. On the top of the pool smelting device 200 , the second feeding port 202 is arranged on the side wall of the molten pool smelting device 200 , and the electrothermal reduction device 300 is provided with a slag discharge port 301 and a metal discharge port 302 . The nozzle of the first side blowing lance 210 is submerged below the liquid level of the molten pool in the molten pool smelting device 200 through the second feeding port 202 to inject fuel and oxygen-enriched air into the molten pool.

[0041] The electrothermal reduction device 300 is provided with three electrodes 310 (self-baking electrodes), which are powered by AC. A second side bl...

Embodiment 2

[0044] The difference with embodiment 1 is:

[0045] The molten pool smelting device 200 does not use a submerged side blowing lance to inject fuel.

[0046] Through the above smelting process, the recovery rate of vanadium element is 93wt%, the recovery rate of iron element is 88wt%, and the comprehensive energy consumption is 7% higher than that of Example 1.

Embodiment 3

[0048] The difference from Embodiment 1 is that the number of electrodes 310 is two.

[0049] Through the above smelting process, the recovery rate of vanadium element is 94wt% and the recovery rate of iron element is 87wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com