Vehicle chassis, vehicle and control method of vehicle chassis

A control method and vehicle technology, applied to vehicle components, axles, wheels, etc., can solve the problems of poor sports performance and safety, complex chassis structure, multiple weights, etc., to improve the load/vehicle weight ratio and carrying capacity, Improve running stability and safety, and avoid the effect of dead weight of the car body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

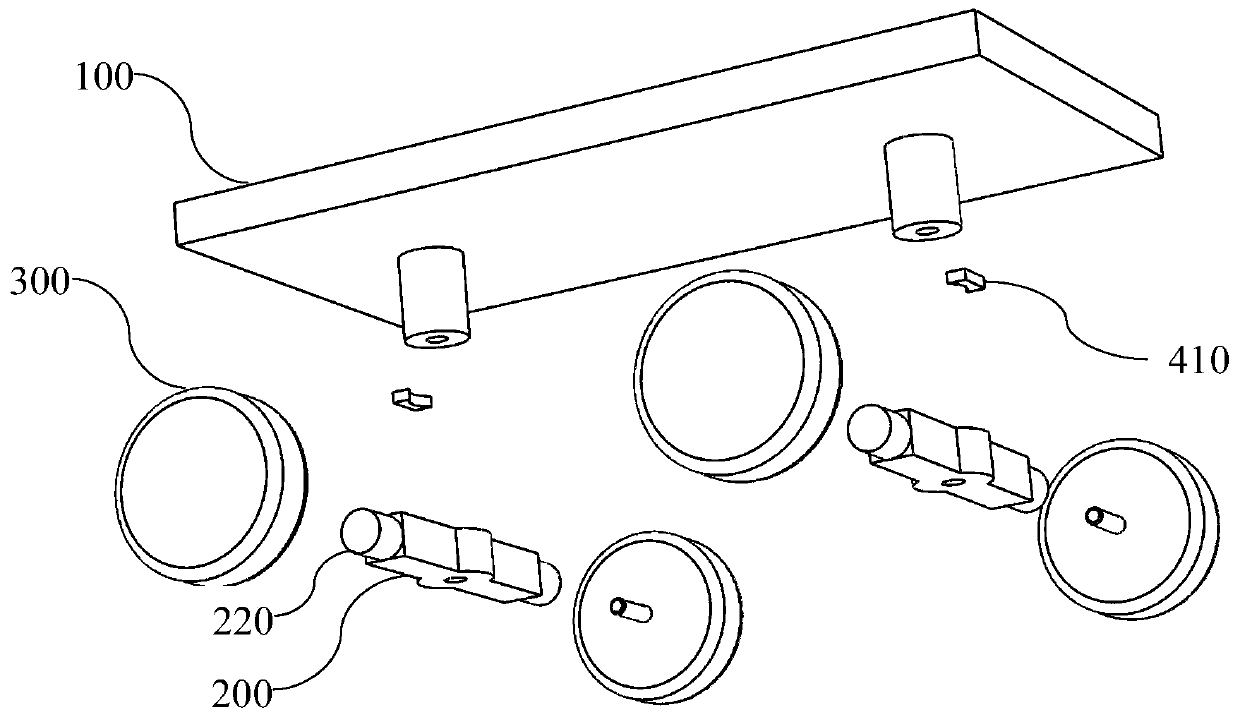

[0055] see Figure 1 to Figure 6 , in the embodiment of the present invention, two steering axles 200 are provided, and the two steering axles 200 are arranged one behind the other; There are four control wheels, and each control wheel is rotatably connected to the two ends of the steering bridge 200, and the two power wheels 300 connected to the same steering bridge 200 are always coaxial. The working modes of the vehicle chassis include steering mode, lateral displacement mode and self-balancing mode.

[0056] In the embodiment of the present invention, the two steering axles 200 are respectively rotatably connected to the bottom of the vehicle body 100 near the central axis, and the two steering axles 200 are arranged one after the other. Rotate in the opposite direction to reduce the steering radius of the vehicle; it can also control the two front and rear steering axles 200 to rotate in the same direction so that the vehicle can be displaced laterally, which improves th...

Embodiment 2

[0075] see Figure 6 , in the embodiment of the present invention, two steering axles 200 are provided, and the two steering axles 200 are arranged one behind the other, and four control wheels are provided; the steering axle 200 includes a connecting rod 211 and two steering knuckle arms 212, and the two steering knuckles One end of the arms 212 is respectively hinged with the connecting rod 211 , the other ends of the two steering knuckle arms 212 are respectively connected to the control wheels, and the middle parts of the two steering knuckle arms 212 are both rotatably connected with the vehicle body 100 . The working modes of the vehicle chassis include steering mode and lateral displacement mode.

[0076] In the embodiment of the present invention, the two steering axles 200 are respectively rotatably connected to the bottom of the vehicle body 100 near the central axis, and the two steering axles 200 are arranged one after the other. Rotating in the opposite direction...

Embodiment 3

[0091] In the embodiment of the present invention, there are two steering axles 200, the two steering axles 200 are arranged one behind the other, and there are four control wheels; At the bottom of the body 100, the axial directions of all the truck wheels are parallel. The operating modes of the chassis of the vehicle include steering modes.

[0092] In the embodiment of the present invention, the two steering axles 200 are respectively rotatably connected to the bottom of the vehicle body 100 near the central axis, and the two steering axles 200 are arranged one after the other. Rotating in the opposite direction reduces the turning radius of the vehicle; additional support bridges and load-carrying wheels can improve the running stability and load-carrying capacity of the vehicle body 100 . Preferably, the truck wheel is a power wheel 300 with a built-in brushless hub motor, so that the supporting bridge and the truck wheel can also provide additional power for the operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com