Garbage classification system and process

A garbage sorting and garbage technology, which is applied in classification, solid separation, and separation of solids from solids with airflow, etc. It can solve the problems of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

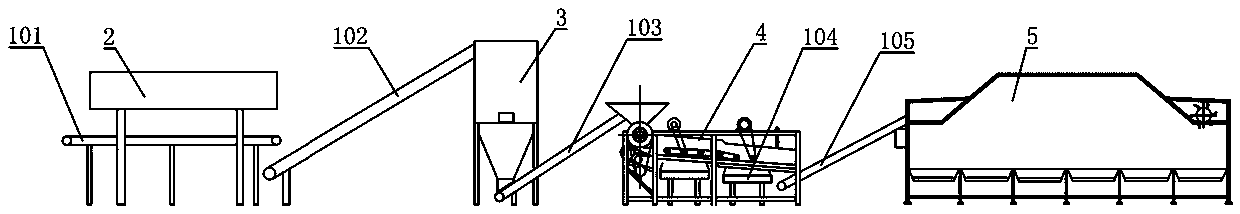

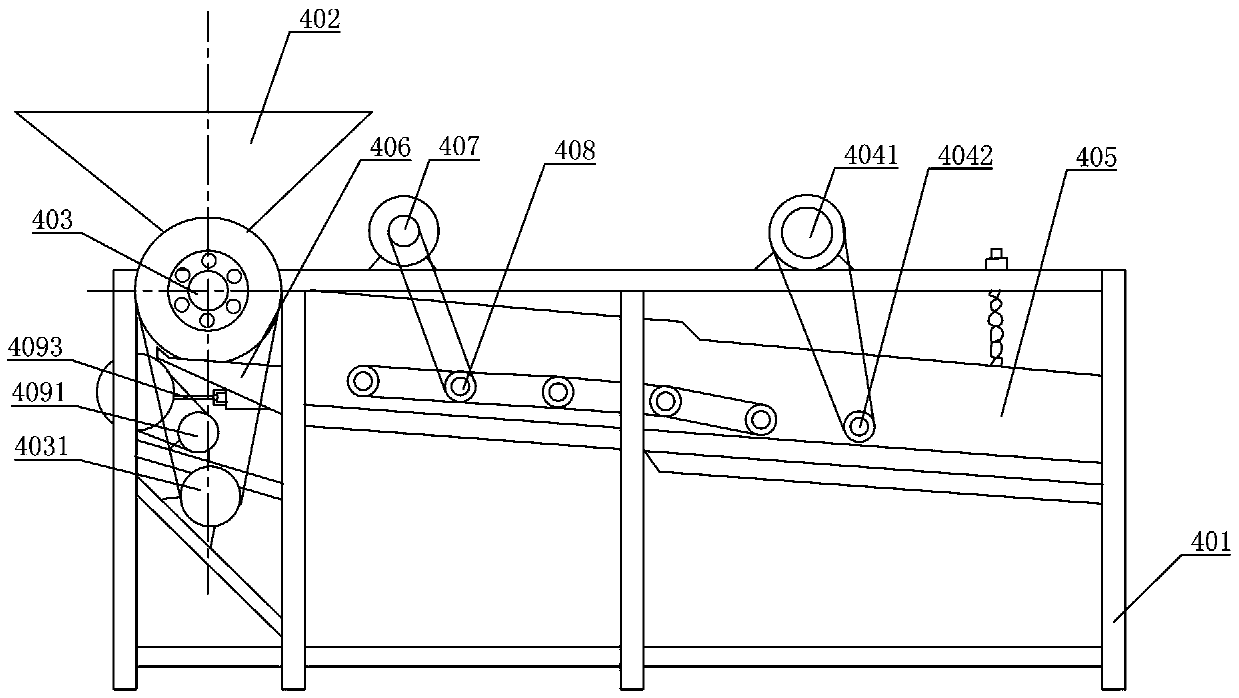

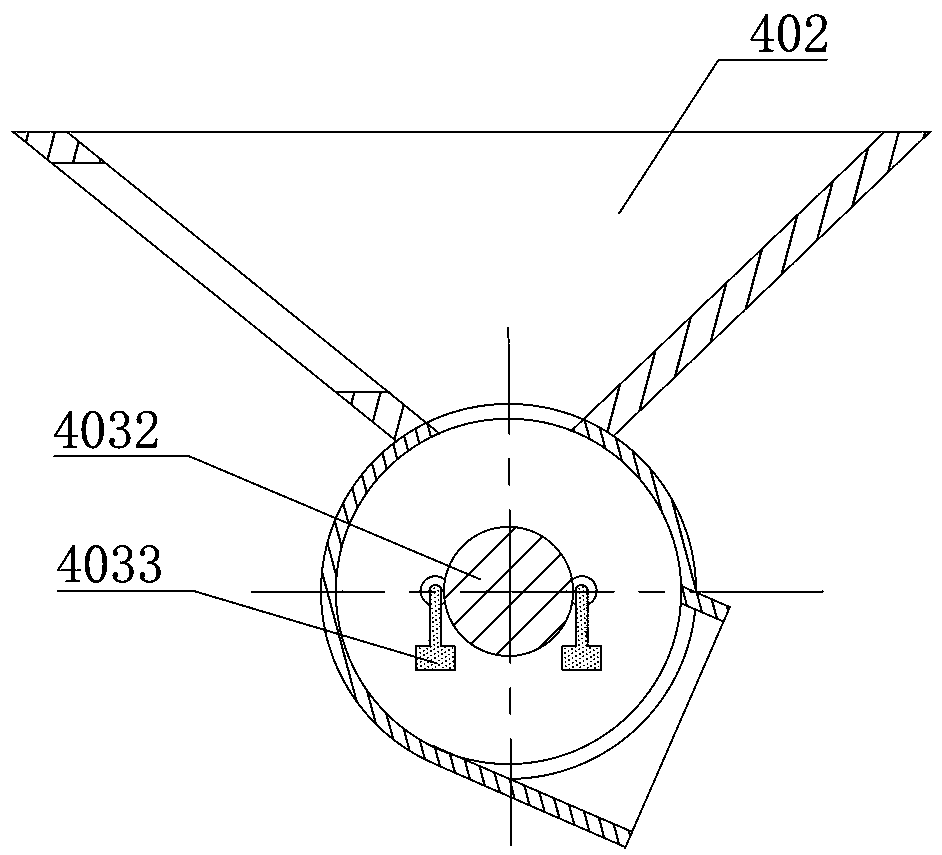

[0034] Such as Figure 1 to Figure 8As shown, the garbage sorting system includes a conveyor, a magnetic separator 2 and a bin 3, and the conveyor includes a first conveyor 101, a second conveyor 102, a third conveyor 103, a fourth conveyor 104 and a first conveyor 104. Five conveyors 105, a magnetic separator 2 is arranged above the first conveyor 101, an inclined second conveyor 102 is provided at one end of the first conveyor 101, and a feed bin 3 is provided at one end of the second conveyor 102, and the feed bin 3 is provided with a bag-breaking motor 302 and a bag-breaking roller 301, the bag-breaking motor 302 and the bag-breaking roller 301 are connected by transmission, and the bag-breaking roller 301 is rotated and arranged at the lower part of the bin 3, and a third conveyor is arranged below the bin 3 103, the third conveyor 103 transports the garbage to the crushing and screening machine 4, the crushing and screening machine 4 is provided with a screening plate 40...

Embodiment 2

[0049] Such as Figure 1 to Figure 8 Shown, based on the technology of the garbage sorting system of embodiment one, comprises the following steps:

[0050] Step 1: Continuously dump the garbage onto the first conveyor 101, manually select large-volume objects, and use the magnetic separator 2 to absorb and screen magnetic metals and utensils containing magnetic metals;

[0051] Step 2: Transport the garbage obtained after screening in step 1 to the silo 3 through the second conveyor 102, and the bag-breaking roller 301 at the lower part of the silo 3 breaks the garbage bags, and transfers the garbage to the third conveyor on machine 103;

[0052] Step 3: The third conveyor 103 transports the garbage broken in step 2 to the crushing and screening machine 4 to separate organic matter from construction waste and domestic waste, and transports it to the storage and processing area through the fourth conveyor 104 .

[0053] Step 4: Transport the unsorted large-volume garbage obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com