Energy-saving type roller type fine grinding device for PVC new material machining

A technology of fine pulverization and new material, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of unsatisfactory pulverization effect of new PVC materials and reduce production quality, so as to speed up the screening speed, save the utilization rate, and avoid pulverization. Not in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

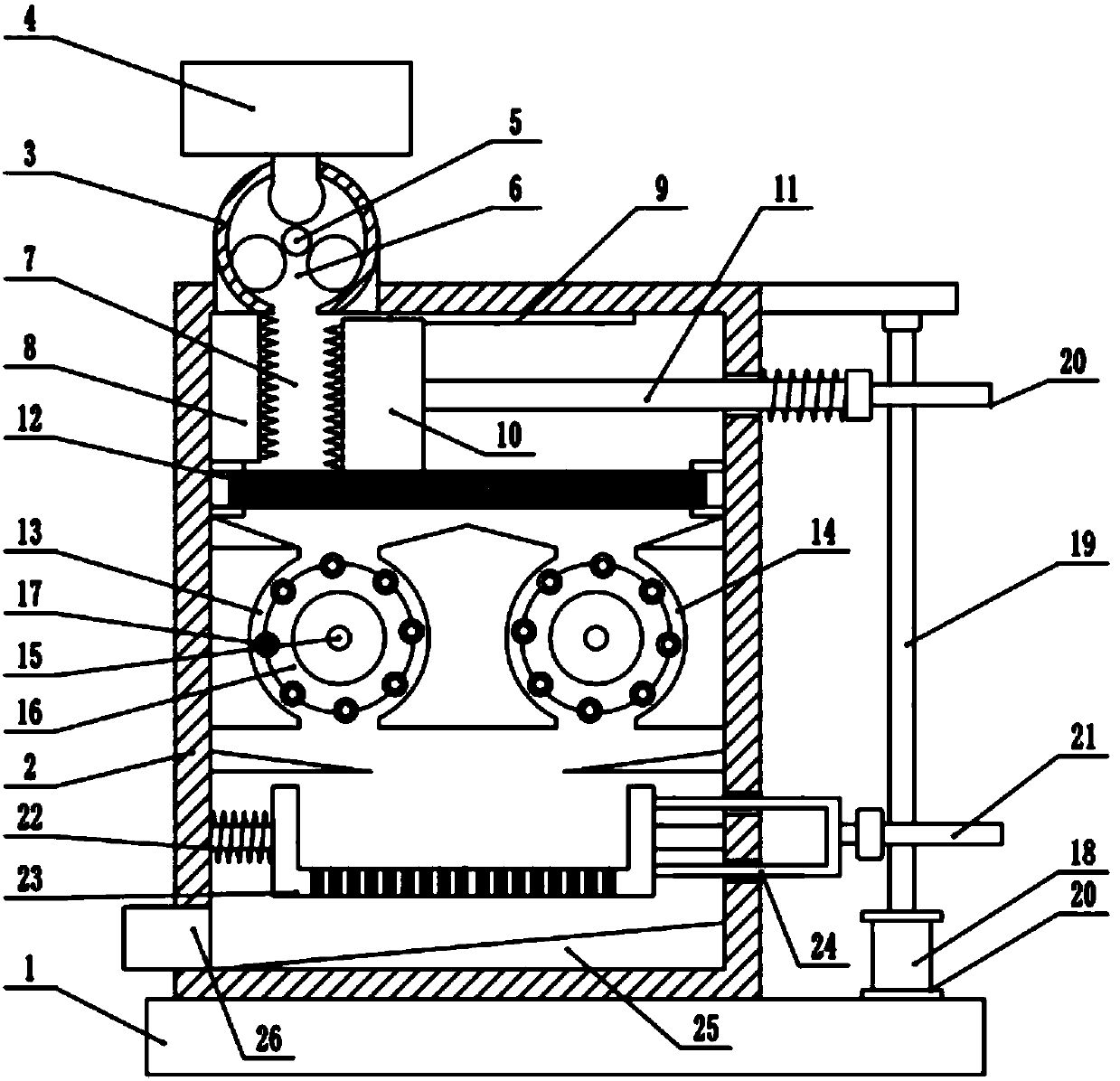

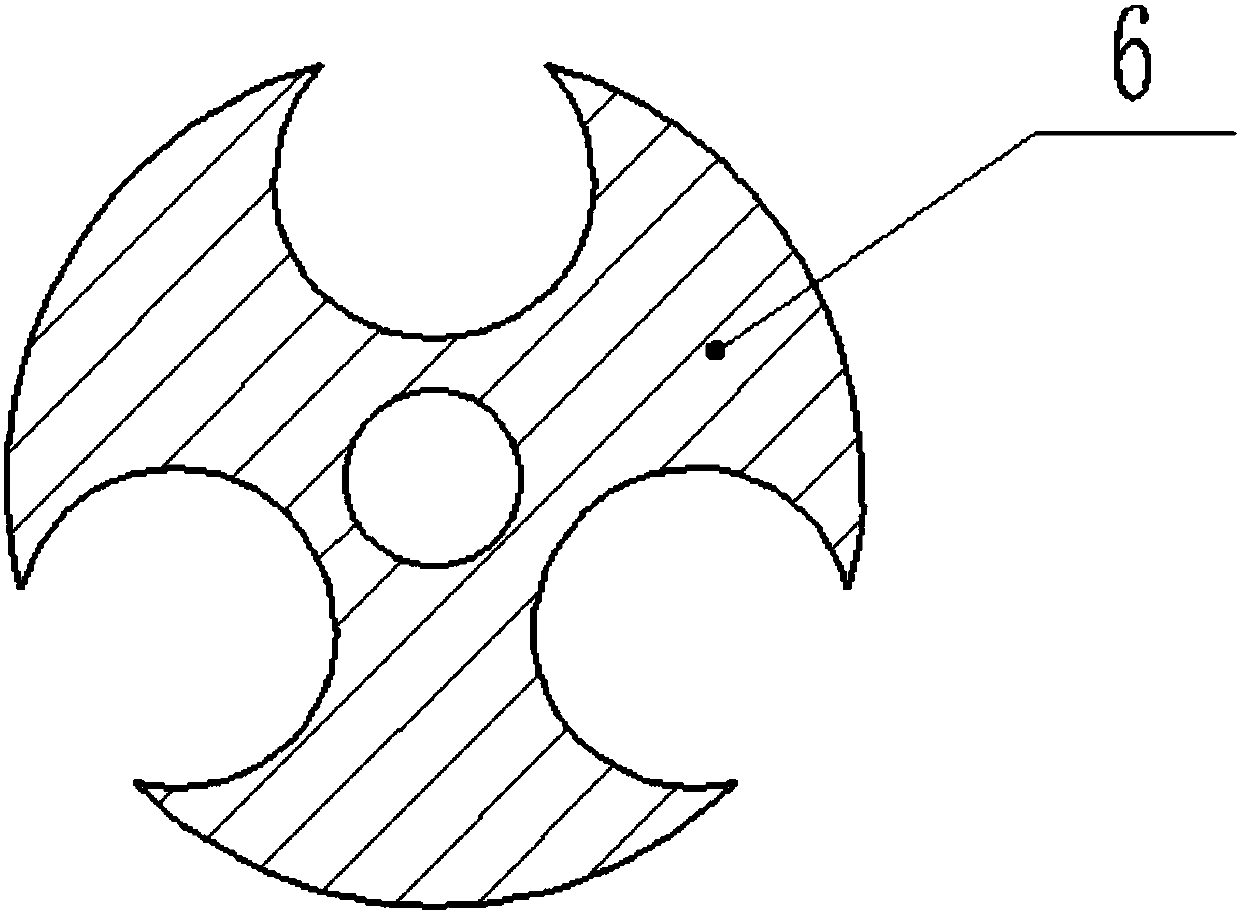

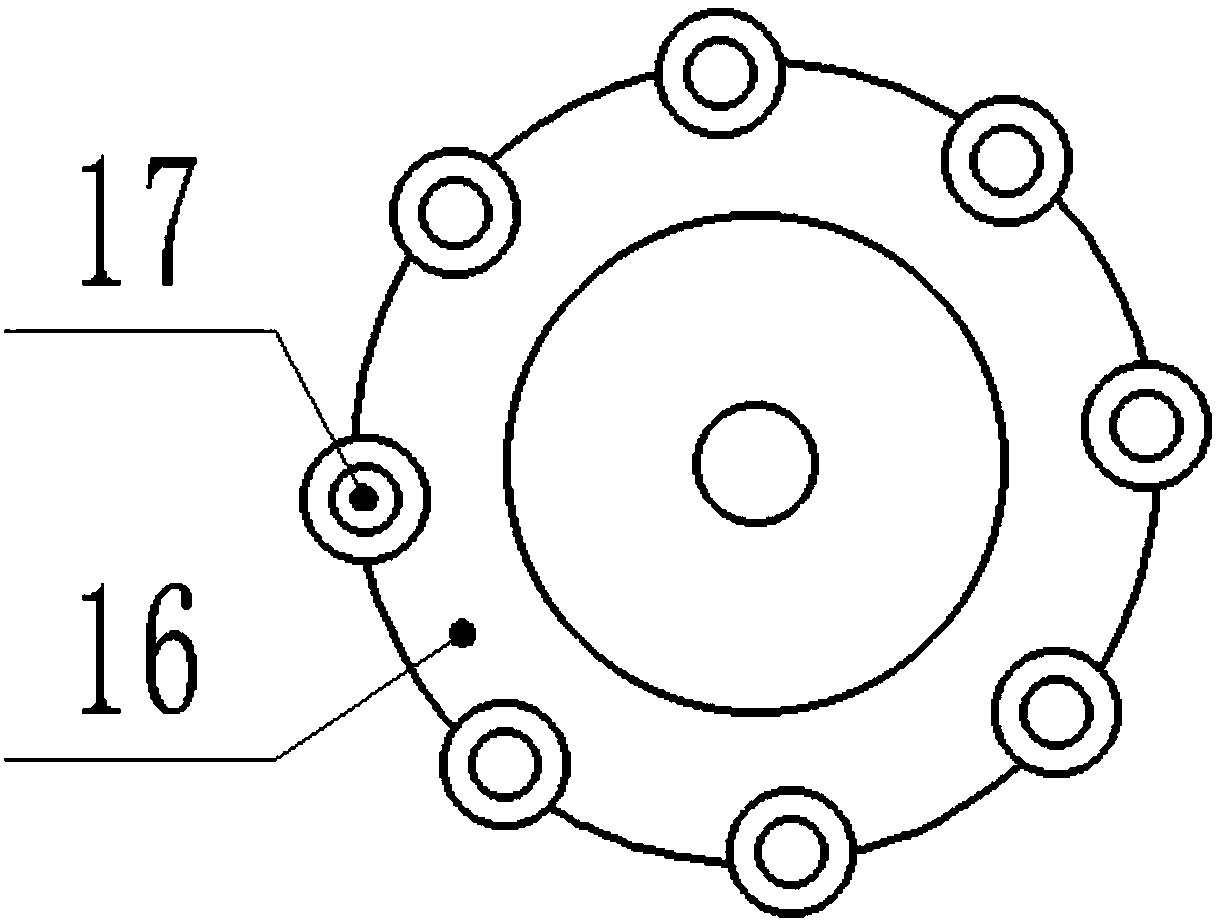

[0021] see Figure 1-3 , an energy-saving type PVC new material processing roller fine crushing device, including a base 1, a crushing box 2, a material distribution device 3, a drive motor 18 and a screening tank 23, the base 1 is provided with a crushing box 2, crushing The boxes 2 and 1 are fixedly connected by bolts, the top left side of the crushing box 2 is provided with a material distribution device 3, and the upper side of the material distribution device 3 is connected with a material storage box 4, and the inside of the material distribution device 3 is a circular cavity and The rear side of the material distribution device 3 is fixedly equipped with a material distribution motor 5, the output shaft of the material distribution motor 5 is forward and the output shaft of the material distribution motor 5 stretches into the material distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com