A pipeline reactor that can fully react and has self-cleaning function

A pipeline reactor and full reaction technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of occupying a large land area, not being able to clean, Inconvenient use and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

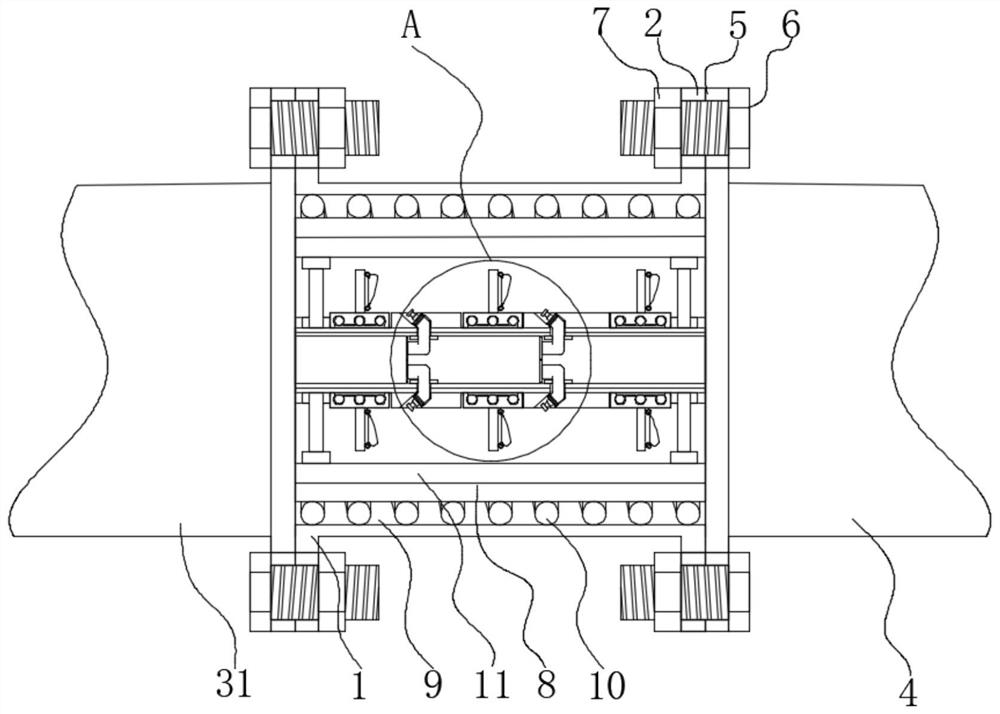

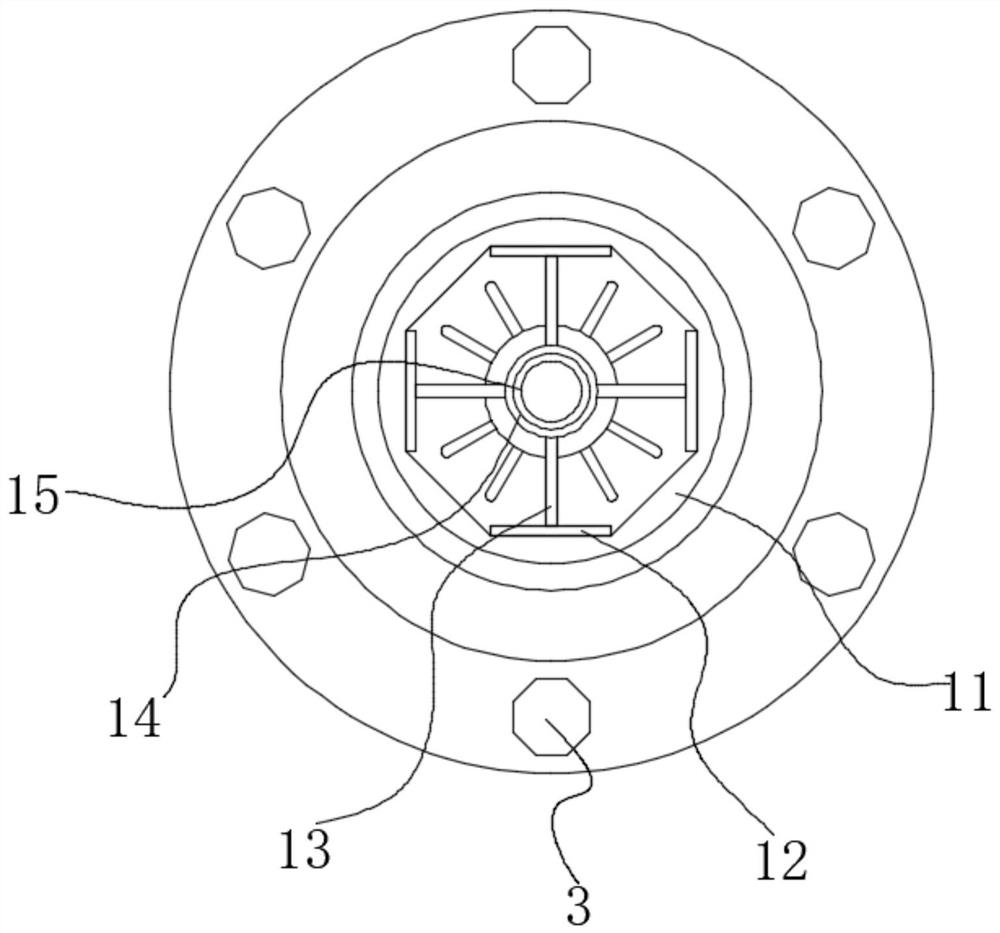

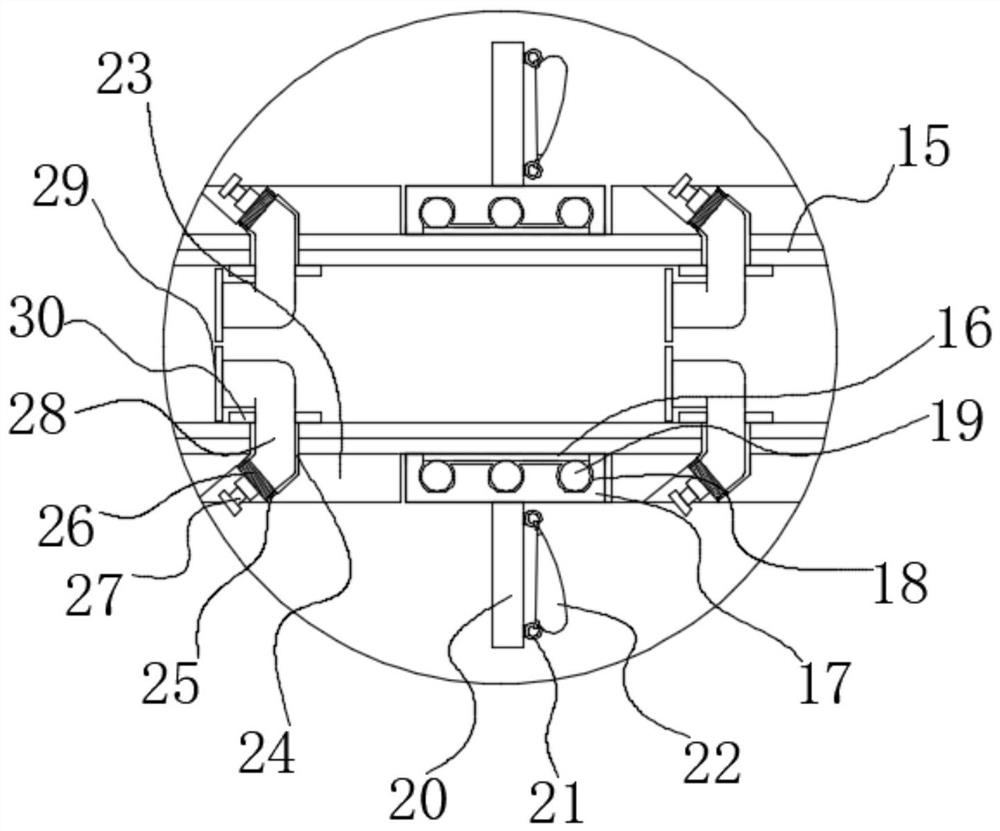

[0023] like Figure 1-3 As shown, the embodiment of the present invention provides a pipeline reactor capable of fully reacting and having a self-cleaning function, including a main pipeline 1, and the inside of the main pipeline 1 includes an auxiliary pipeline 8, a heating tank 9, a heating ring 10, and a diamond-shaped liner 11. Jacket 14 and inner tube 15, the outer side of inner tube 15 includes rolling sleeve 16 and rotating sleeve 17, the inner side of rotating sleeve 17 includes rolling groove 18, ball 19, connecting ring 21 and auxiliary paddle 22, inner tube 15 The inner side of the nozzle includes a nozzle 27, a guide pipe 28 and a water inlet funnel 29. The heating tank 9 is located on the inner side of the main pipeline 1, and the main pipeline 1 is flexibly connected with the heating ring 10 through the heating tank 9. The main pipeline 1 includes a first The flange side 2, and the first flange side 2 is welded to both ends of the main pipe 1, the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com