Magnetic attraction type hot compress electrode patch

An electrode patch, magnetic suction technology, applied in the directions of heating appliances for treatment, cooling appliances for treatment, contraceptives, etc., can solve problems such as cumbersome operation, and achieve convenient connection operation, easy processing, and easy connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

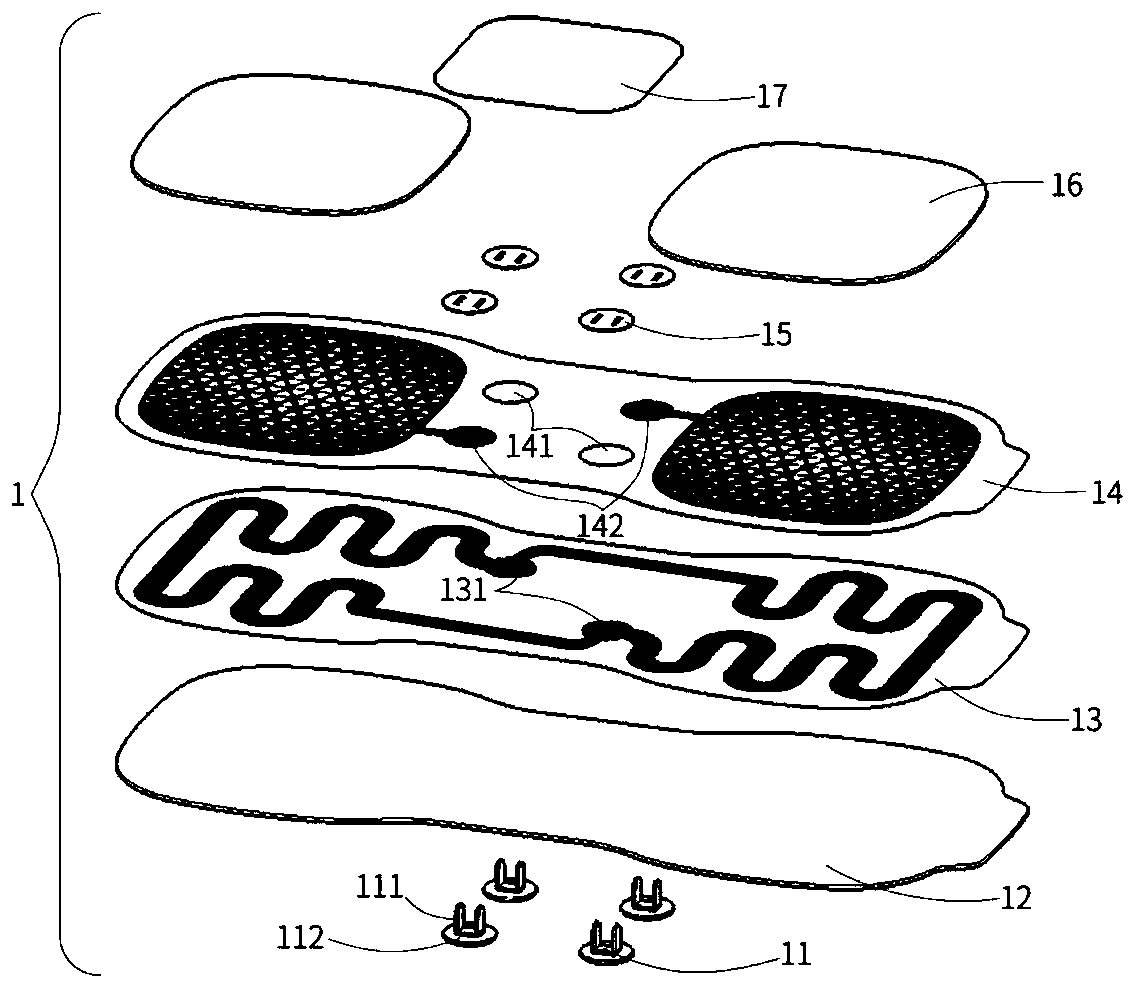

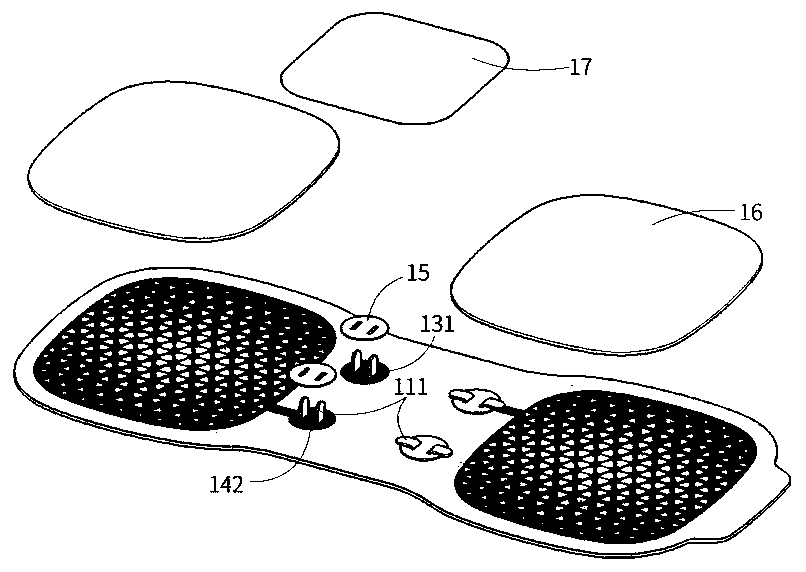

[0025] Example 1 of a magnetic suction type hot compress electrode patch, such as figure 1 and 2 As shown, it includes a flexible leather sheet 12, a flexible heating sheet 13, a flexible conductive sheet 14, a metal gasket 15, a self-adhesive hydrogel 16, an insulating patch 17 and a conductive magnetic button 11. The flexible leather sheet 12, the flexible heating sheet substrate, the flexible conductive sheet substrate and the insulating patch 17 are all insulating materials.

[0026] The flexible leather sheet 12, the flexible heating sheet 13, and the flexible conductive sheet 14 are arranged from bottom to top, and the edges of the flexible leather sheet 12, the flexible heating sheet 13, and the flexible conductive sheet 14 are aligned; the contact surface of the flexible heating sheet base material and the flexible conductive sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com