Production process of soft package instant fish block based on microwave fast sterilization technology

A production process and flexible packaging technology, which is applied in the production process field of flexible packaging ready-to-eat fish pieces, can solve the problems of destroying the nutritional components of fish meat, reducing water activity, increasing osmotic pressure, etc., and achieves elimination of uneven effect, strong sterilization effect, and cooling fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

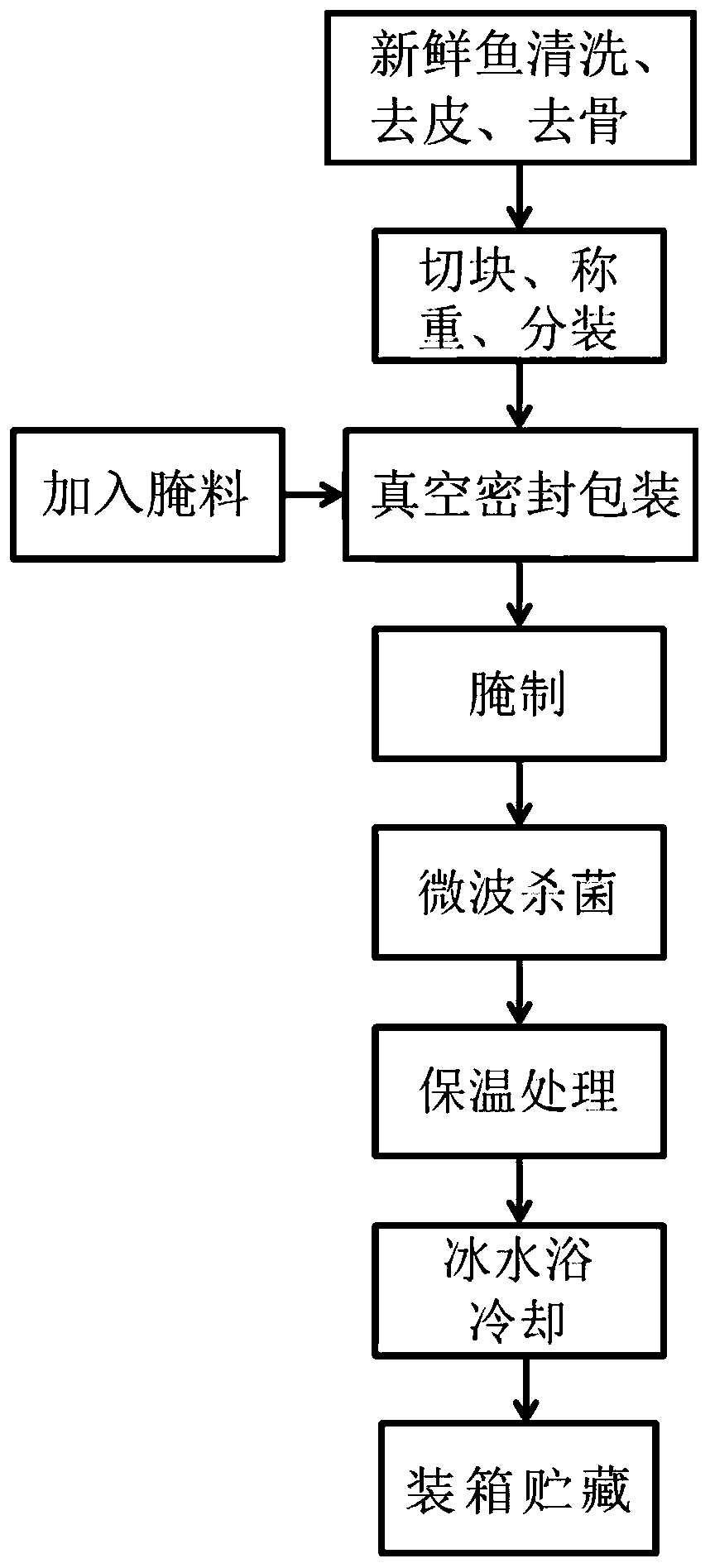

[0040] Such as figure 1 As shown, it is a flow chart of the production technology of the soft-packed ready-to-eat salmon that adopts the technical solution of the present invention, and the salmon is Atlantic salmon produced in Chile, including the following steps:

[0041] (1) Raw material pretreatment: fresh salmon is washed, peeled and boned;

[0042] (2), subpackage: cut the fish meat into small pieces of 100*60*16mm3, weigh them, and put them into retort bags;

[0043] (3) Preparation of marinade: white wine 1.5%, sesame oil 0.5%, chicken essence 0.8%, salt-reduced soy sauce 0.6%, ginger powder 8%, garlic powder 8%, fennel powder 1.5%, onion powder 1.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com