Hole transport material and preparation method thereof, application of hole transport material, and perovskite solar cell containing hole transport material

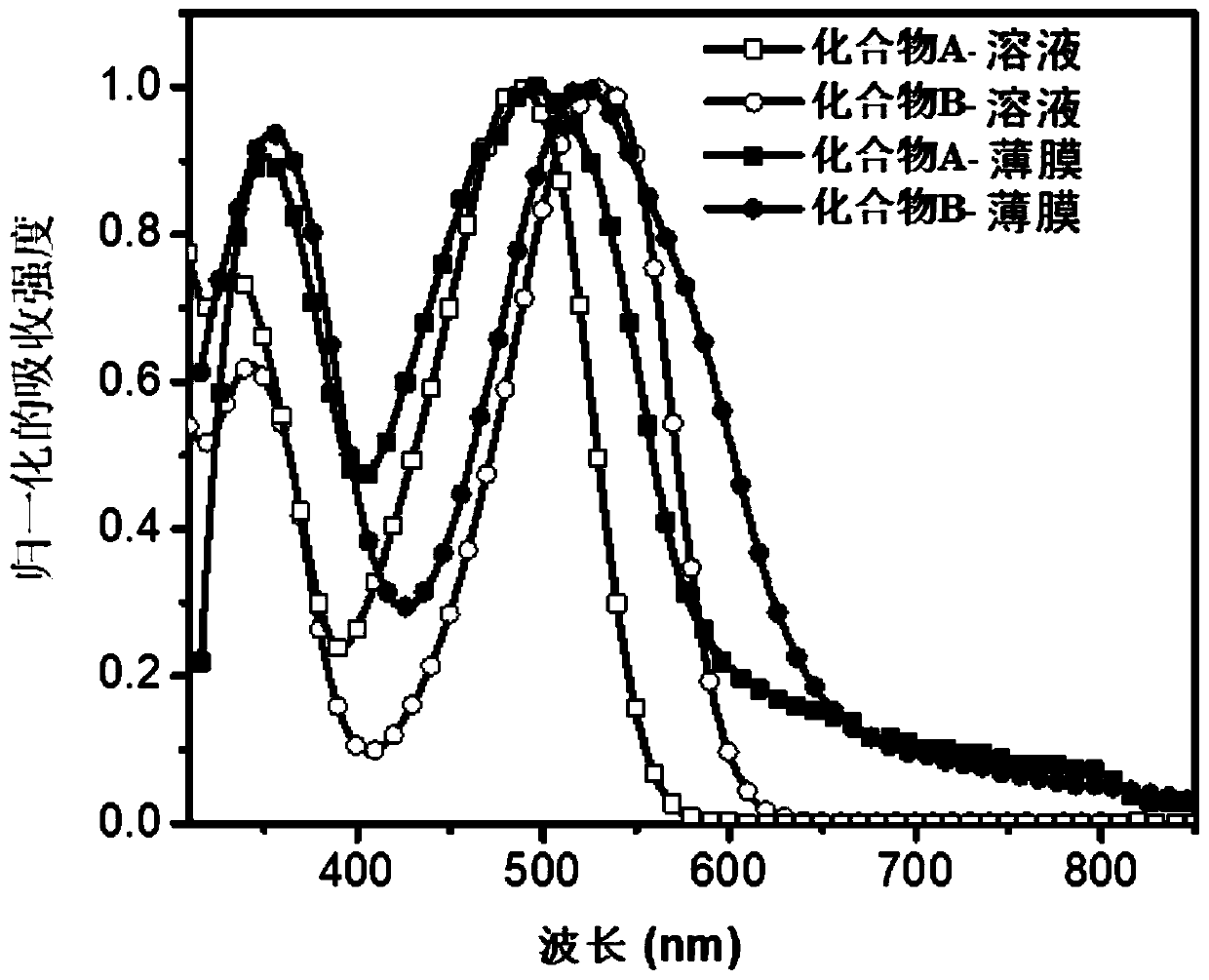

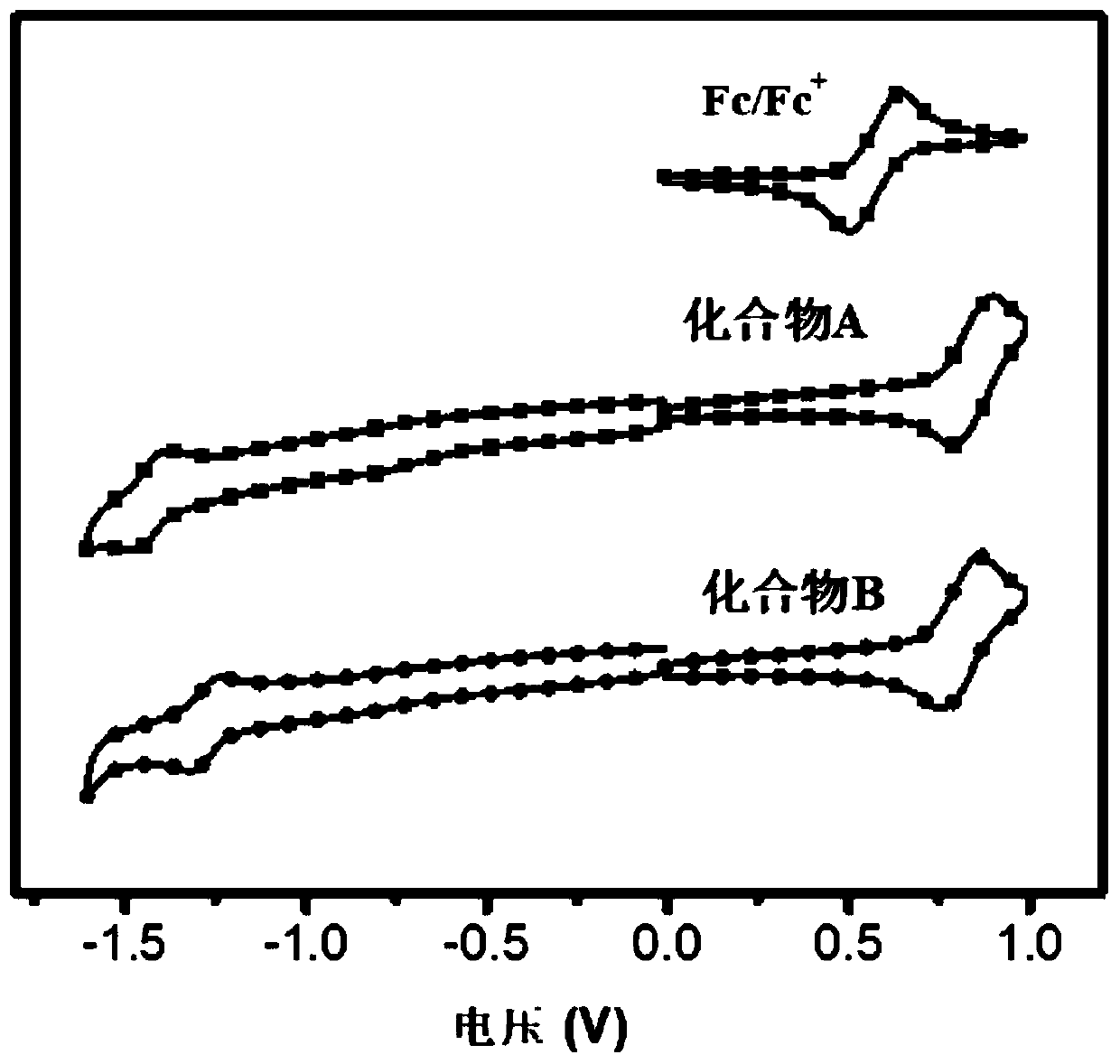

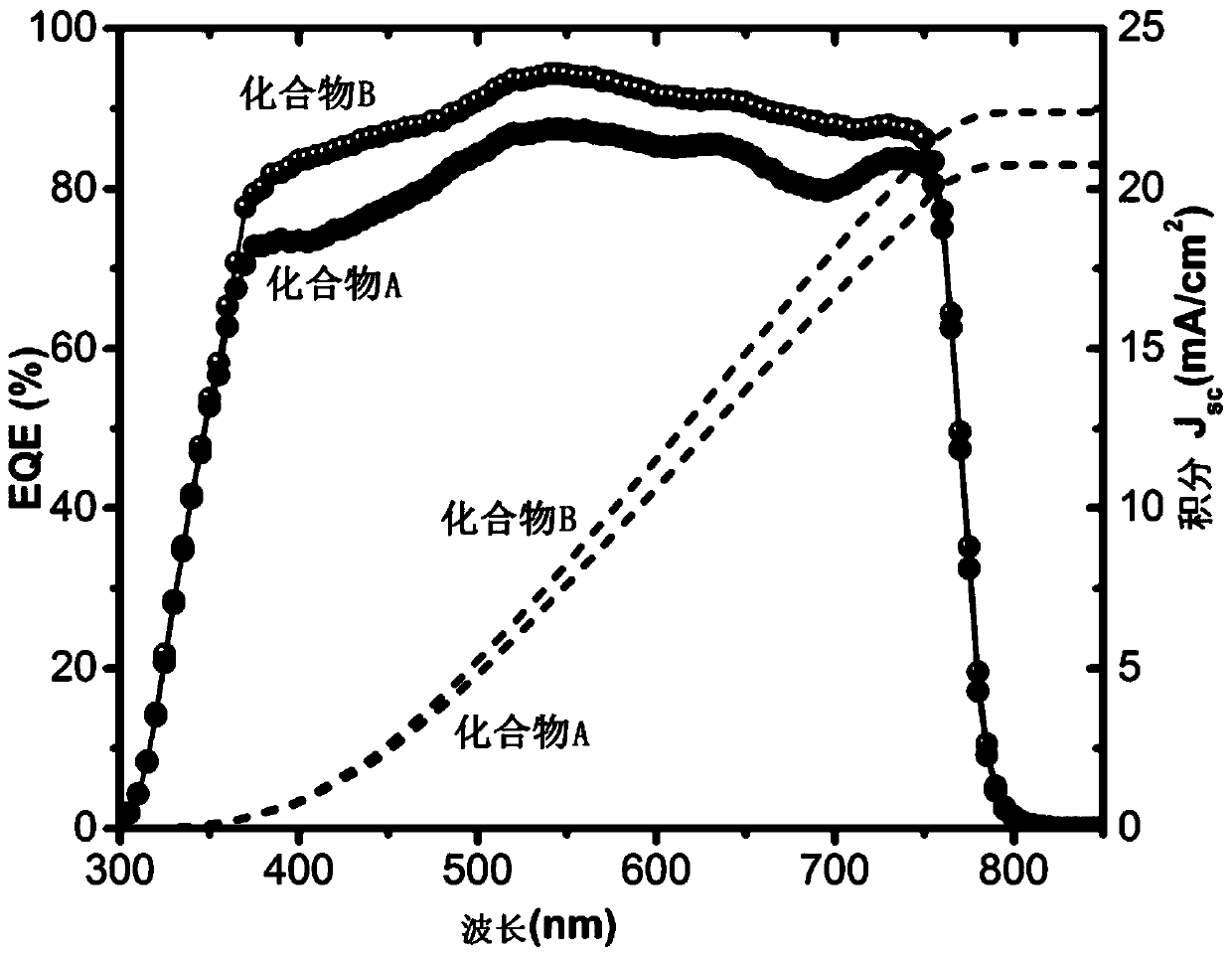

A technology for hole transport materials and solar cells, applied in the field of solar cells, can solve the problems of poor solubility of hole transport materials, reduce stability, raise the HOMO energy level of polymers, etc., and achieve controllable optoelectronic properties and good film morphology. , the effect of high photoelectric conversion efficiency and external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0077] A hole transport material has the following structure:

[0078]

[0079] The preparation method is as follows:

[0080]

[0081] (1) Synthesis of compound 1: 4,4'-dimethoxydiphenylamine (458mg, 2.0mmol), p-bromoiodobenzene (848mg, 3.0mmol), Pd 2 (dba) 3 (92mg, 0.1mmol), dppf (54mg, 0.085mmol), sodium tert-butoxide (952mg, 10mmol), placed in a two-necked bottle; after pumping argon three times, add anhydrous toluene 20mL; react under argon protection After heating to reflux for 24 hours, the reaction system was cooled to room temperature, the solvent was spun out, and the initial product was further purified through a column to obtain compound 1 with a mass of 380 mg and a yield of 50%.

[0082] 1 H NMR (400MHz, CDCl 3 )δ: 7.26(d, J=8.9Hz, 2H), 7.05(d, J=8.9Hz, 4H), 6.84(d, J=8.9Hz, 4H), 6.81(d, J=8.9Hz, 2H) ,3.81(s,6H).

[0083] (2) Synthesis of Compound 2: Compound 1 (3.84g, 10mmol), bis(pinacolate) diboron (3.81g, 15mmol), Pd(dppf)Cl 2 (365mg, 0.5mmol), p...

preparation example 2

[0095] A hole transport material has the following structure:

[0096]

[0097] The preparation method is as follows:

[0098]

[0099] (1) Synthesis of compound 8: the synthetic steps refer to compound 4, and the yield is 82%.

[0100] 1 H NMR (400MHz, CDCl 3 ): δ7.63(d, J=5.3Hz, 2H), 7.30(d, J=5.4Hz, 2H), 4.43-4.36(m, 2H), 1.85-1.78(m, 2H), 1.51-1.28( m,18H),0.90(t,J=6.8Hz,3H).

[0101] (2) Synthesis of Compound 9: Compound 8 (200mg, 0.38mmol), N-bromosuccinimide (208mg, 1.16mmol) were placed in a two-necked flask; 7mL of anhydrous chloroform and anhydrous N were added, N'-dimethylformamide 2mL; After reacting at room temperature for 12 hours, pour it into water, extract with chloroform, combine the organic phases, dry with anhydrous sodium sulfate, spin out the solvent, and the initial product is further purified by column to obtain compound 9, mass It was 204 mg, and the yield was 80%.

[0102] 1 H NMR (400MHz, CDCl 3):δ7.22(s,2H),4.32-4.29(m,2H),1.80-1.72(m,...

preparation example 3

[0109] A hole transport material has the following structure:

[0110]

[0111] The preparation method is as follows:

[0112]

[0113] (1) Compound 12 was synthesized according to the method for compound 1 in Preparation Example 1, and the yield was 50%.

[0114] 1 H NMR (400MHz, CD 2 Cl 2 ):δ7.29-6.87(m,28H),3.81(s,12H).

[0115] (2) Compound 13 was synthesized according to the method for synthesizing Compound 2 in Preparation Example 1, with a yield of 61%.

[0116] 1 H NMR (400MHz, CDCl 3 ):δ7.64(br,2H),7.08-7.06(m,8H),6.97(br,6H),6.88-6.83(m,12H),3.81(s,12H),1.34(s,12H).

[0117] (3) Compound C was synthesized according to the method for compound A in Preparation Example 1, and the yield was 70%.

[0118] 1 H NMR (400MHz, CDCl 3 ): δ7.83(s, 2H), 7.45(d, J=8.7Hz, 4H), 7.09(d, J=8.9Hz, 16H), 7.03-6.99(m, 12H), 6.90(d, J= 8.9Hz,8H),6.86(d,J=8.9Hz,16H),4.26-4.22(m,2H),3.82(s,24H),1.76-1.72(m,2H),1.45-1.30(m,18H ), (t,J=7.0Hz,3H).

[0119] 13 C NMR (400MHz,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com