Cutting process of PVA (polyvinyl alcohol) composite

A technology of polyvinyl alcohol and composite materials, which is applied in the field of medical supplies, can solve the problems of falling off, being easily torn apart, and the decline of mechanical properties, so as to achieve low production costs, reduce the falling of broken fibers, and reduce the generation of debris Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

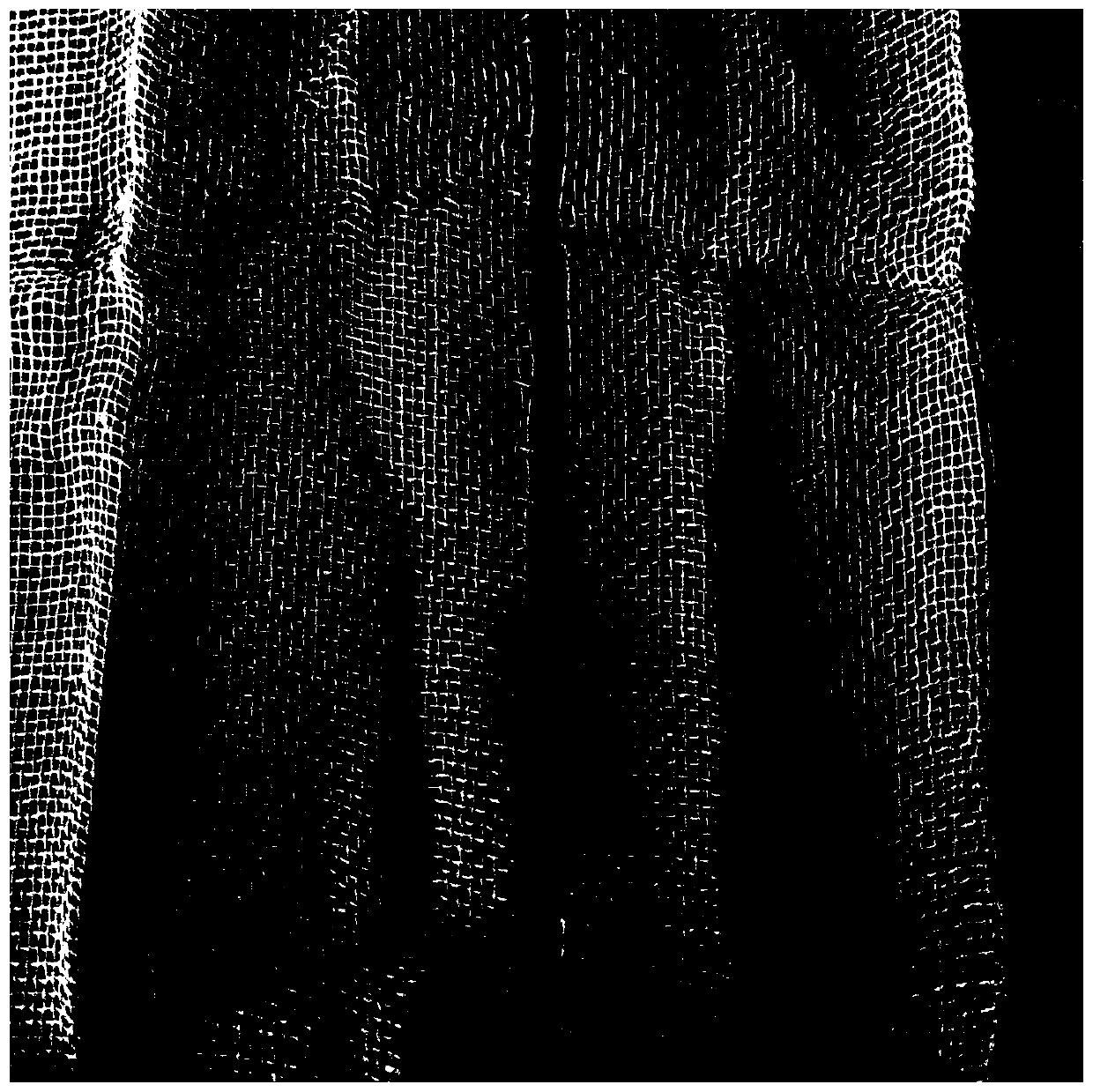

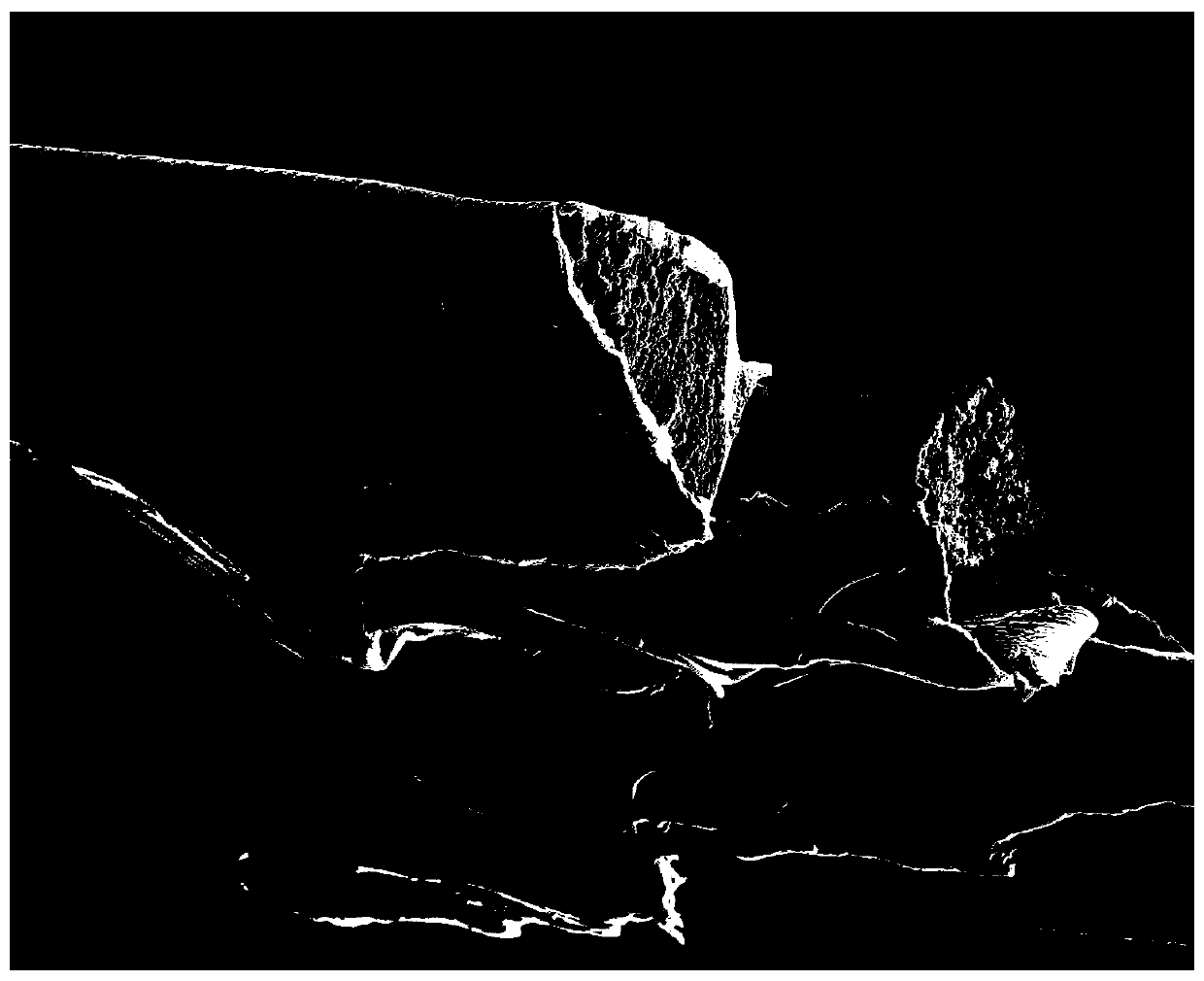

Image

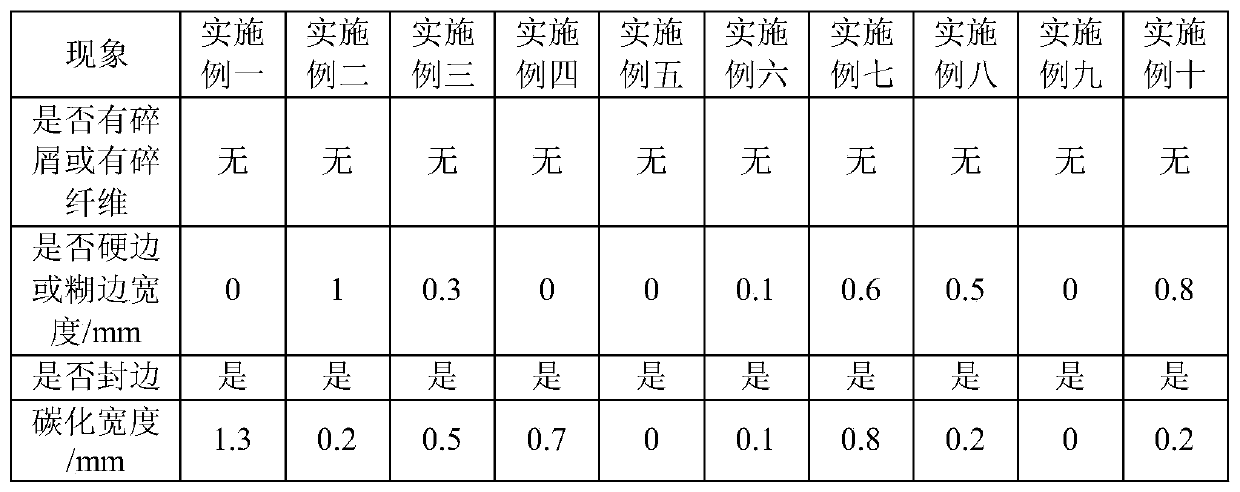

Examples

Embodiment 1

[0033] A kind of cutting process of polyvinyl alcohol composite material, spread the 75wt% polyvinyl alcohol and 25wt% cotton yarn blended woven fabric on the cutting table, and then use the heating knife at 230 ℃ along the predetermined cutting line to weave the polyvinyl alcohol composite fabric Cutting is carried out to separate the corresponding part of the polyvinyl alcohol composite woven fabric.

[0034] Here, the alcohol alkalinity of polyvinyl alcohol is 90%, the degree of polymerization is 1700, and the cutting position is always under the protection of argon during the cutting process.

Embodiment 2

[0036] A cutting process of polyvinyl alcohol composite materials, laying the non-woven fabric co-made of 75wt% polyvinyl alcohol and 25wt% PP on the cutting table, and then using a heating knife at 330°C along the predetermined cutting line on the polyvinyl alcohol composite non-woven fabric Cutting is performed to separate the corresponding portion of the polyvinyl alcohol composite non-woven fabric.

[0037] Here, the alcohol alkalinity of polyvinyl alcohol is 95%, the degree of polymerization is 2400, and the cut is always under the protection of neon gas during the cutting process.

Embodiment 3

[0039] A cutting process of polyvinyl alcohol composite materials, laying 85wt% polyvinyl alcohol, 7wt% PP and 8wt% cotton yarn film on the cutting table, and then using a 420°C heating knife along the predetermined cutting line to compound polyvinyl alcohol Cutting is performed on the film to separate the corresponding portion of the polyvinyl alcohol composite film.

[0040] Here, the alcohol alkalinity of polyvinyl alcohol is 100%, the degree of polymerization is 2600, and the cut is always under the protection of helium during the cutting process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com