Preparation method for breathable bacteriostatic tree-protecting film

A technology for protective film and trees, applied in the field of landscaping, can solve the problems of waterproof, antibacterial, and unsatisfactory air permeability, and achieve the effect of enhanced bactericidal and antibacterial effect and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

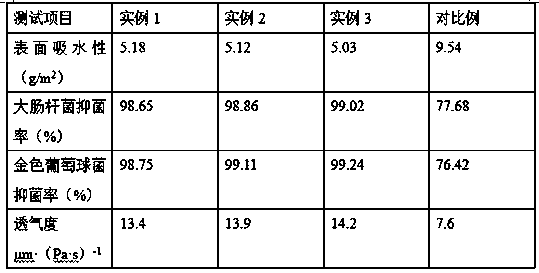

Examples

example 1

[0032] Put the corn cob into the pulverizer and grind for 30 minutes to get the corn cob crushed product, mix the corn cob crushed product with 20% sodium hydroxide solution at a mass ratio of 1:8, pour it into the reaction kettle, and heat it up to 70°C, stir and react for 20 minutes, filter, remove the filtrate, and collect the filter residue; mix the above filter residue with the malic acid solution with a mass fraction of 20% at a mass ratio of 1:5, put it into a high-temperature and high-pressure cooking tank, and set the high-temperature and high-pressure The temperature in the cooking tank is 180°C and the pressure is 1.8MPa. Under the above conditions, high temperature and high pressure cooking for 5h, discharging, filtration and separation to obtain a filter cake; the above filter cake, phenol, and 5% sodium hydroxide solution by mass fraction The mass ratio is 2:1:4, and then put into the vacuum distillation device after mixing. Set the temperature in the vacuum disti...

example 2

[0034] Put the corn cob into the pulverizer and grind for 35 minutes to get the corn cob crushed product, mix the corn cob crushed product with 20% sodium hydroxide solution at a mass ratio of 1:8, pour it into the reaction kettle, and heat it up to 75°C, stir and react for 25 minutes, filter, remove the filtrate, and collect the filter residue; mix the above filter residue with the malic acid solution with a mass fraction of 20% at a mass ratio of 1:5, put it into a high-temperature and high-pressure cooking tank, and set the high-temperature and high-pressure The temperature in the cooking tank is 190°C and the pressure is 1.9MPa. Under the above conditions, high temperature and high pressure cooking for 6h, discharging, filtration and separation to obtain a filter cake; the above filter cake, phenol, and 5% sodium hydroxide solution by mass fraction The mass ratio is 2:1:4, and then put into the vacuum distillation device, set the temperature in the vacuum distillation devic...

example 3

[0036] Put the corn cob into the pulverizer to grind for 40 minutes to get the corn cob crushed product, mix the corn cob crushed product with 20% sodium hydroxide solution at a mass ratio of 1:8, pour it into the reaction kettle, and heat it up to 80°C, stirred and reacted for 30 minutes, filtered, removed the filtrate, and collected the filter residue; mixed the above filter residue with the malic acid solution with a mass fraction of 20% at a mass ratio of 1:5, put it into a high-temperature and high-pressure cooking tank, and set the high-temperature and high-pressure The temperature in the cooking tank is 200°C and the pressure is 2.0MPa. Under the above conditions, high temperature and high pressure cooking for 7 hours, discharge, filtration and separation to obtain a filter cake; the above filter cake, phenol, and 5% sodium hydroxide solution by mass fraction The mass ratio is 2:1:4, and then put into the vacuum distillation device after mixing. Set the temperature in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com