Green light thermally activated delayed fluorescent material and its preparation method, organic electroluminescent device

A technology of thermally activated delayed and fluorescent materials, used in luminescent materials, electric solid devices, chemical instruments and methods, etc., can solve the problem of lack of heavy metal Ir complexes, achieve fast crossing constant, increase luminous efficiency, low single or triple line The effect of energy level difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

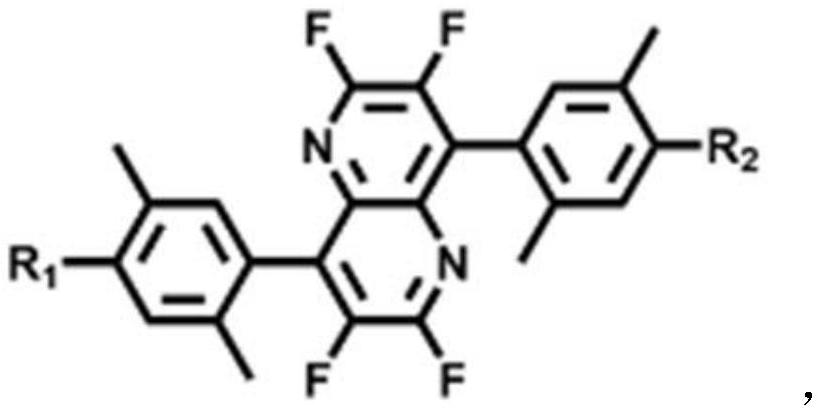

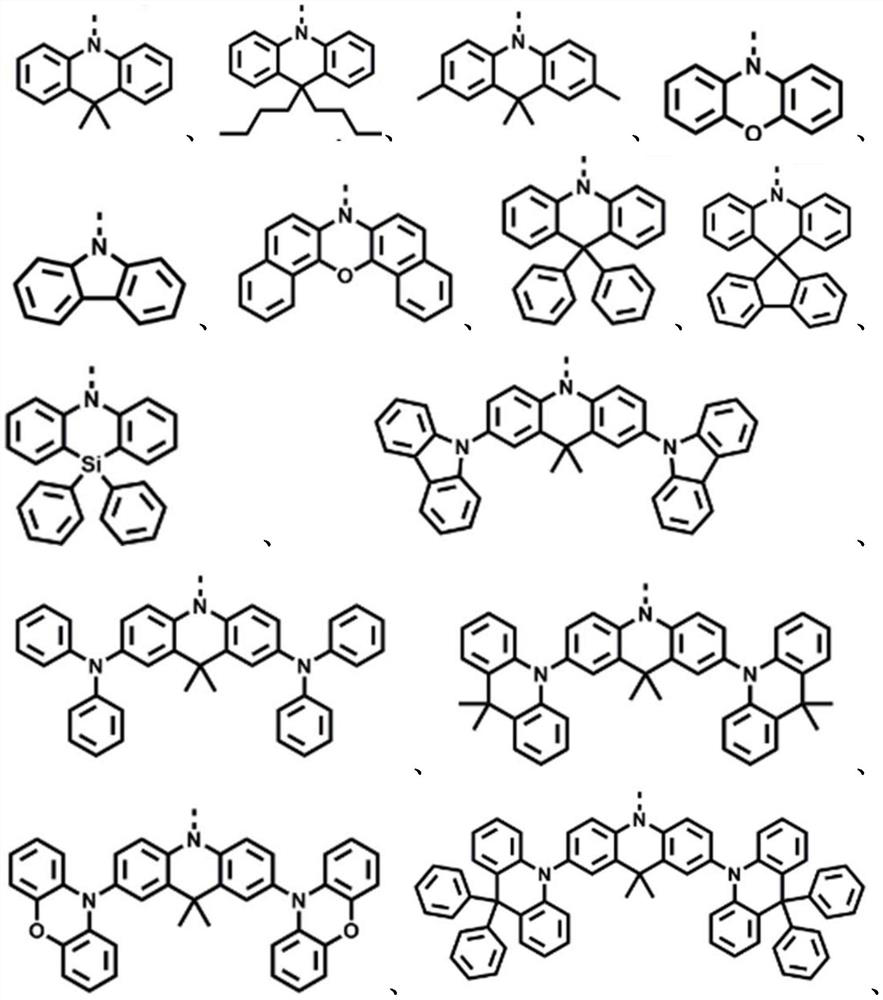

[0038] Embodiment 1 provides a method for preparing a green-light thermally activated delayed fluorescent material, comprising the following steps: putting a compound containing a bispyridine group, a nitrogen-containing aromatic compound, and a catalyst into a reaction vessel to form a first mixed solution, At least one fluorine atom is connected to the bispyridine group; the reaction vessel is evacuated with argon, and an alcohol compound and a first solvent are added to the reaction vessel to obtain a second mixed solution; the The second mixed solution was heated to 120° C. and reacted for 24 hours, then cooled to form a third mixed solution; the third mixed solution was poured into the second solvent to form a fourth mixed solution; dichloromethane was used to prepare the fourth mixed solution performing three extractions and merging the organic phases to obtain a target compound solution; performing column chromatography separation and purification on the target compound ...

Embodiment 2

[0044] Embodiment 2 provides a preparation method of a green light heat-activated delayed fluorescent material. The difference from Embodiment 1 is that the compound of the bispyridine group is 4,8-bis(4-bromo-2,5- Dimethylphenyl)-2,3,6,7-tetrafluoro-1,5-naphthyridine, the nitrogen-containing aromatic compound is phenoxazine (2.20 g, 12 mmol).

[0045] Through the preparation method of Example 2, 2.3 g of green powder was finally obtained, with a yield of 60%. The specific chemical reaction equation is as follows:

[0046]

Embodiment 3

[0049] Embodiment 3 provides a preparation method of a green-light heat-activated delayed fluorescent material. The difference from Embodiment 1 is that the compound of the bispyridine group is 4,8-bis(4-bromo-2,5- Dimethylphenyl)-2,3,6,7-tetrafluoro-1,5-naphthyridine; the nitrogen-containing aromatic compound is 9,9'-dimethylacridine (2.51g, 12mmol) .

[0050] Through the preparation method of Example 3, 2.5 g of green powder was finally obtained, with a yield of 61%. The specific chemical reaction equation is as follows:

[0051]

[0052] By preparing the green light thermally activated delayed fluorescent molecular material through the synthesis method provided by the invention, the green light thermally activated delayed fluorescent molecular material can be effectively synthesized, and at the same time, the synthesis efficiency can be improved. Wherein, embodiment 3 is the best embodiment, and productive rate is the highest.

[0053] In order to verify whether the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com