Extractive preparation method of sinomenine hydrochloride in orienavine

A technology of sinomenine hydrochloride and Qingfengteng, which is applied in the field of extraction and preparation of sinomenine hydrochloride from Qingfengteng, can solve the problems of increasing impurities, large consumption of hydrochloric acid, and large amount of alkali, so as to reduce environmental pollution and reduce The effect of reducing production cost and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a method for extracting and preparing sinomenine hydrochloride from Caulis chinensis, comprising the following steps:

[0037] (1) Take Qingfengteng and add it at a concentration of 1.0×10 -4 ~0.3mol.L -1 Wetting with hydrochloric acid converts the sinomenine in Qingfengteng into sinomenine hydrochloride; the main function of hydrochloric acid wetting is to convert the sinomenine in Qingfengteng into sinomenine hydrochloride; the water solubility of sinomenine is poor , need to use organic solvents, such as: benzene, to be dissolved from Qingfengteng; while sinomenine hydrochloride is very water-soluble and can be directly dissolved in water, so the sinomenine in Qingfengteng is converted into sinomenine hydrochloride After alkali, it can improve its water solubility to a large extent, so that only pure water can be used to extract sinomenine hydrochloride from Qingfengteng. Also because of this principle, in the hydrochloric acid wetting stage ...

experiment example 1

[0049] 1. Purpose of the experiment

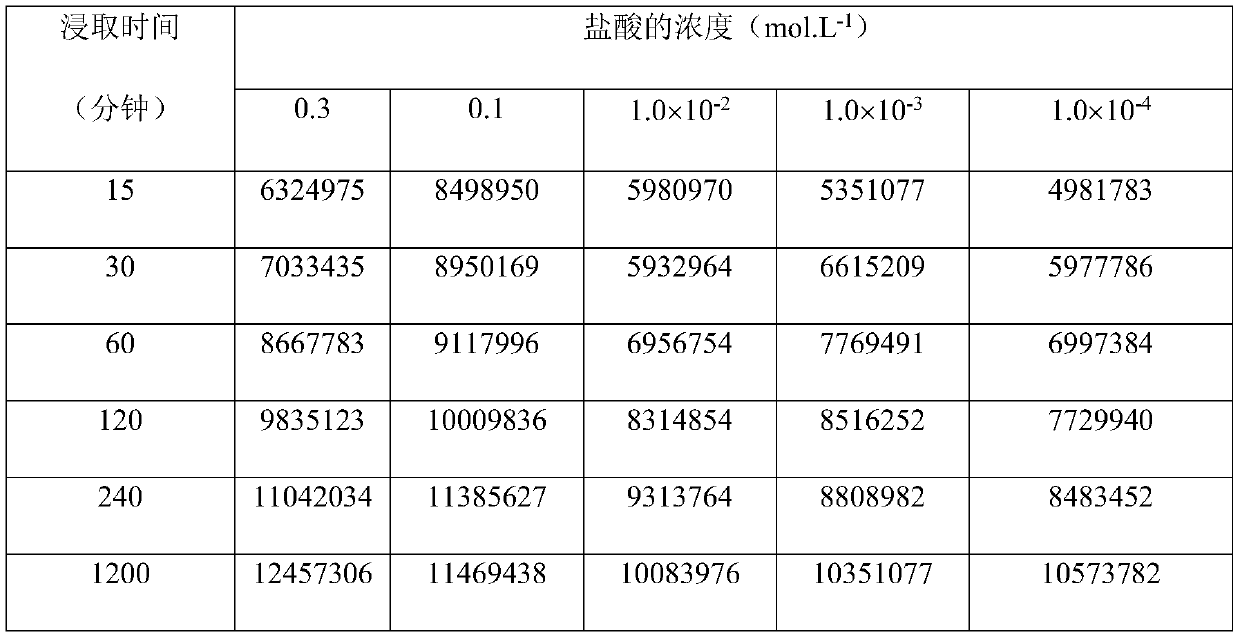

[0050] In this experiment, after the initial processing of C. chinensis, in the environment of normal temperature (water bath control constant temperature 30 ℃), by using different concentrations of hydrochloric acid, the powder of C. chinensis was leached, and the conversion of sinomenine under static conditions was investigated. Sinomenine hydrochloride and its dissolution from Qingfengteng.

[0051] 2. Experimental materials and instruments

[0052] 2.1 Materials

[0053] Qingfengteng: Purchased in Baoji, Shaanxi Province

[0054] 2.2 Chemical reagents

[0055] Hydrochloric acid (analytical pure): Chengdu Jinshan Chemical Reagent Co., Ltd.

[0056] Pure water is water obtained through secondary reverse osmosis treatment.

[0057] 2.3 Experimental Instruments

[0058] HH-21-4 constant temperature water bath box: Jincheng Guosheng Experimental Instrument Factory, Jintan City, Jiangsu Province

[0059] LC-15C High Performance Liquid...

experiment example 2

[0077] 1. Purpose of the experiment

[0078] In this experiment, the pre-processed Caulis chinensis was crushed to pass through No. 1 pharmacopoeia sieve (10 mesh). Under the environment of normal temperature (water bath control constant temperature 30 ℃), by using different concentrations of hydrochloric acid, the Qingfengteng powder is impregnated, and the crushing fineness is investigated. Under static conditions, the conversion of sinomenine in Qingfengteng Alkali, and the dissolution from Qingfengteng.

[0079] 2. Experimental materials and instruments

[0080] 2.1 Materials

[0081] Qingfengteng: Purchased in Baoji, Shaanxi Province

[0082] 2.2 Chemical reagents

[0083] Hydrochloric acid (analytical pure): Chengdu Jinshan Chemical Reagent Co., Ltd.

[0084] Pure water is water obtained through secondary reverse osmosis treatment.

[0085] 2.3 Experimental Instruments

[0086] Chinese medicine grinder

[0087] HH-21-4 constant temperature water bath box: Jinchen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com