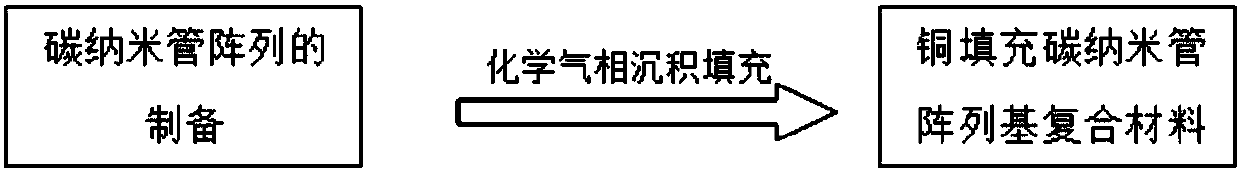

Copper-filled carbon nanotube array-based composite material and preparation method thereof

A carbon nanotube array and composite material technology, applied in the field of nano-micro composite materials, can solve the problems of damaged carbon nanotubes, reduced porosity, unfavorable fillers, etc., to improve thermal conductivity, reduce phonon scattering, and improve thermal performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] As an aspect of the technical solution of the present invention, it relates to a method for preparing a metal-filled carbon nanotube array-based composite material, which includes:

[0042] Provide carbon nanotube arrays;

[0043] Allowing the precursor containing metal elements and the reducing carrier gas to enter the interior of the carbon nanotube array and then react to obtain a plurality of micron metal particles filling the internal pores of the carbon nanotube array;

[0044] Performing high-temperature annealing treatment on the carbon nanotube array filled with micron metal particles, so that the plurality of micron metal particles are fused with each other to obtain a metal-filled carbon nanotube array-based composite material.

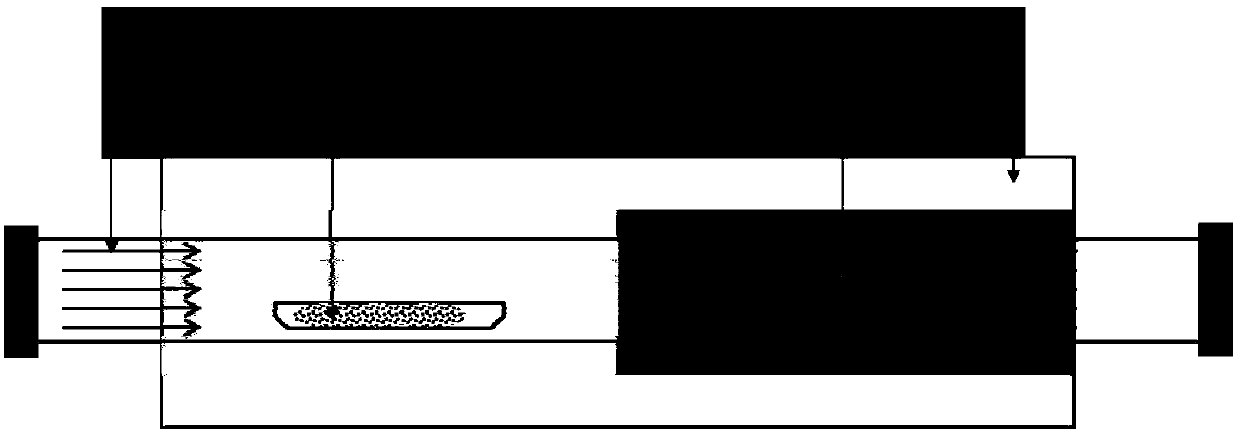

[0045]In some embodiments, the preparation method specifically includes:

[0046] allowing the precursor and the reducing carrier gas to enter the interior of the carbon nanotube array to react to form a plurality of nano metal part...

Embodiment 1

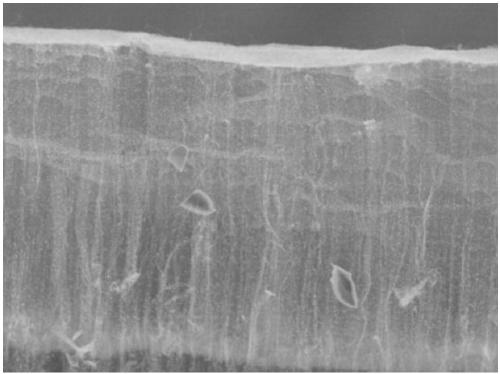

[0083] Put about 200mg of copper sulfate pentahydrate in the quartz boat as a copper-containing precursor, place it in the first temperature zone of the dual-temperature zone tube furnace, and place the carbon nanotubes grown on the silicon substrate in the second temperature zone Array, pass into 50sccm of Ar for 5min, exhaust the air in the device, and pass into 200sccm of H 2 . The temperature of the second temperature zone was first raised to 800°C, and after the temperature was stabilized, the temperature of the first temperature zone was raised to 200°C, and then reacted for 4 hours. After the reaction is over, let the device cool down to room temperature naturally, and then use 500 sccm of Ar to remove the H in the device. 2 Drain clean and remove the sample. Cut the sample from the middle, and its SEM picture is the same as Figure 4a Figure 4c Similarly, it can be seen that copper exists mainly in the form of particles on its surface, where the size of the micron...

Embodiment 2

[0085] About 360mg of copper acetate monohydrate is placed in the quartz boat as a copper-containing precursor, and it is placed in the first temperature zone of the dual temperature zone tube furnace, and the carbon grown on the silicon dioxide substrate is placed in the second temperature zone. For the nanotube array, 500 sccm of Ar was introduced for 5 minutes, the air in the device was exhausted, and then 200 sccm of Ar and H were respectively introduced. 2 . First raise the temperature of the second temperature zone to 1000°C, and after the temperature stabilizes, then raise the temperature of the first temperature zone to 300°C, and then react for 6 hours. After the reaction is over, let the device cool down to room temperature naturally, and then use 500 sccm of Ar to remove the H in the device. 2 Drain clean and remove the sample. Cut the sample from the middle, and its SEM picture is as follows Figure 3a and Figure 3b As shown, the size of the micron copper part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thermal diffusivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com