3D bio-printer head control device and material changing control method of head

A bio-printer and control device technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of printing material pollution, blockage, and viscous material accumulation nozzles, etc., to improve printing efficiency, disassembly and assembly. The effect of convenient use and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

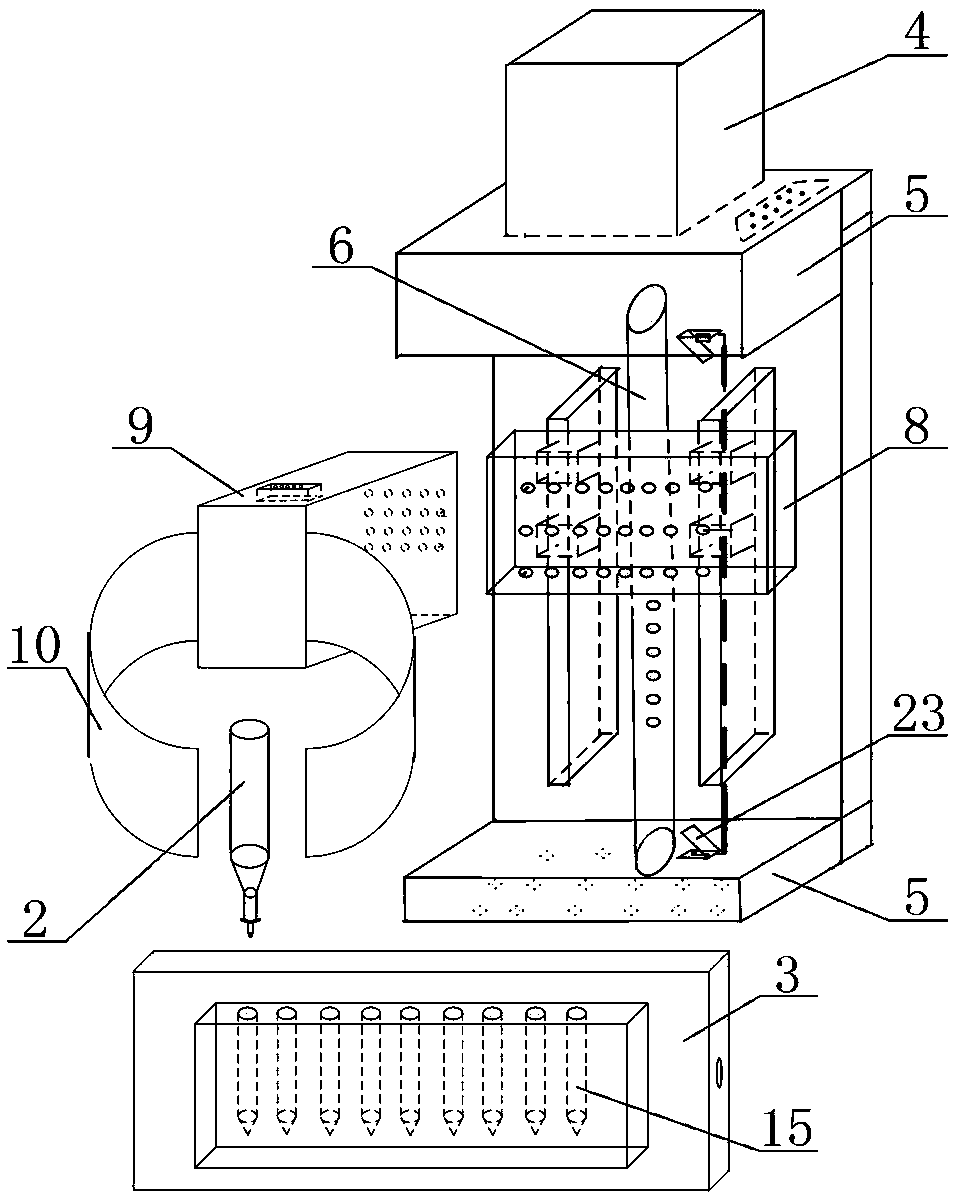

[0035] Such as Figure 1 to Figure 5 As shown, a 3D bioprinter nozzle control device of the present invention includes a motor control frame (1), a printing nozzle (2) and a refueling device (3), and the motor control frame (1) is set on the top of the 3D bioprinter , one side of the motor control frame (1) is provided with a stepping motor (4), and the two ends of the motor control frame (1) are extended outward with fixed beams (5), and the fixed beams (5) A threaded shaft (6) is provided on the top, and the threaded shaft (6) drives the movement of the printing device (7) on the Y-axis printing plane through the stepping motor (4);

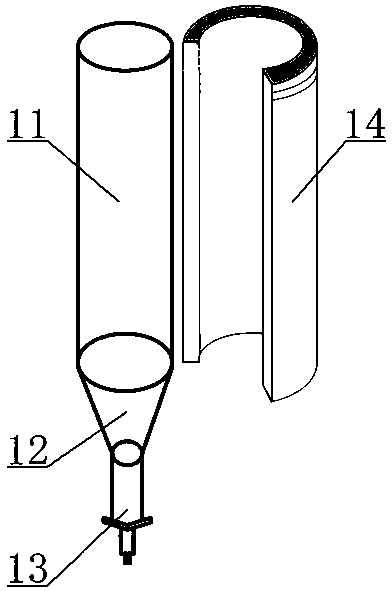

[0036] The printing device (7) includes a connecting end (8) and a fixed end (9), the connecting end (8) and the fixed end (9) are fixed by bolts, and the connecting end (8) and the threaded shaft (6 ) transmission connection, the extension end of the fixed end (9) is provided with a fixing clip (10), and the fixing clip (10) is used to clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com