Automatic adjustment device for rotating knife parallel to outer bamboo wall, bamboo shaping and rotary cutting machine, and method for parallel bamboo wall rotary cutting

An automatic adjustment and angle adjustment technology, which is applied in mechanical equipment, sugarcane machining, wood processing appliances, etc., can solve the problems of inability to rotate bamboo veneer, poor surface quality of bamboo veneer, small friction torque, etc. The knife is parallel to the bamboo section and the outer bamboo wall is accurate, with high continuity and low resistance to rotary cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

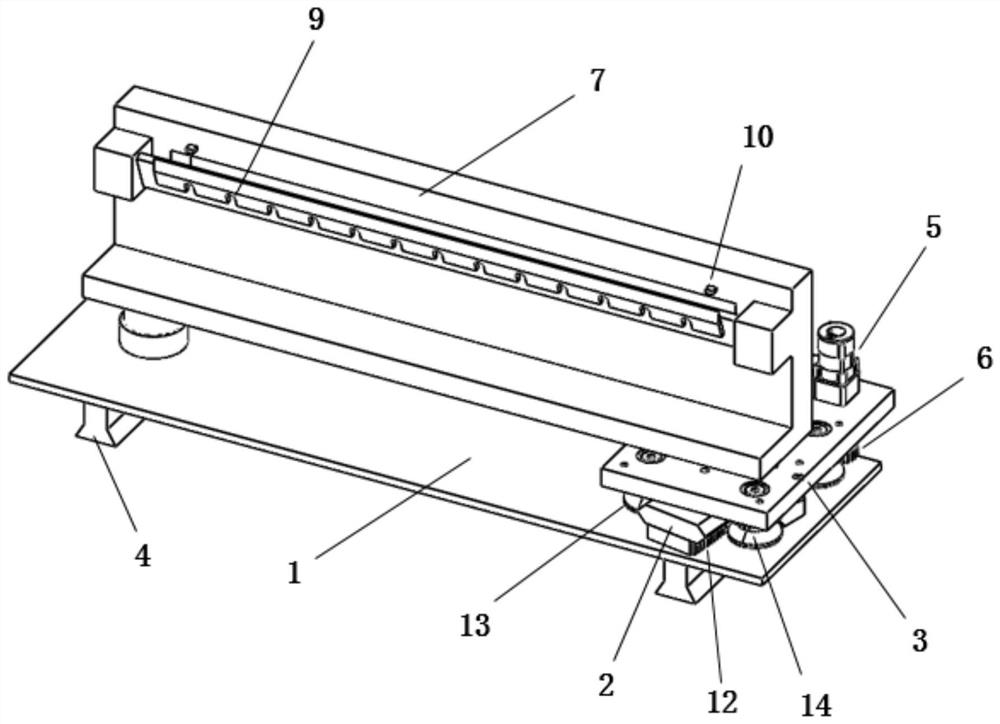

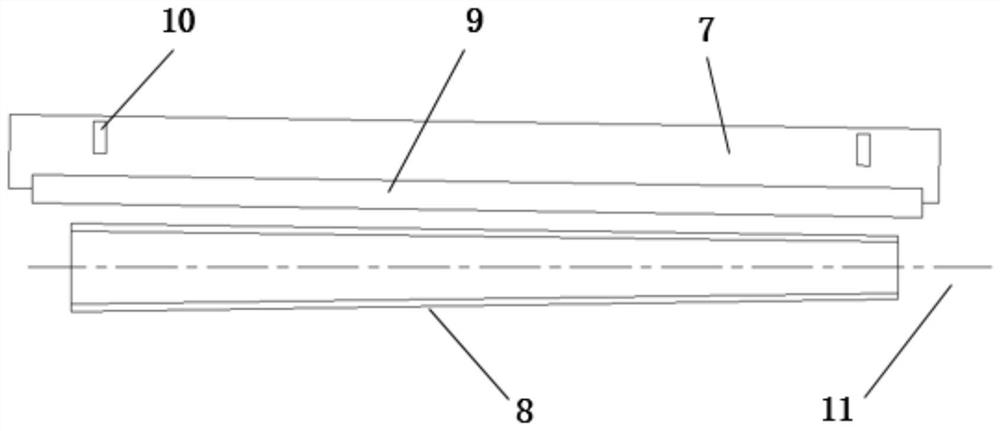

[0038] Such as Figure 1-3 As shown, the invention provides a kind of rotary knife parallel outer bamboo wall automatic adjustment device, comprising:

[0039] Knife rest 7, rotary cutter 9 is installed on the knife rest 7, and one end of knife rest 7 is a hinged end;

[0040] Angle adjustment seat, the other end of knife rest 7 is arranged on the angle adjustment seat, and described angle adjustment seat comprises brake stepper motor 5, makes knife rest 7 rotate around hinged end by brake stepper motor 5;

[0041] The rotary knife parallel adjustment control system is used to control the rotational movement of the brake stepper motor 5 so that the rotary knife 9 is parallel to the outer bamboo wall 8.

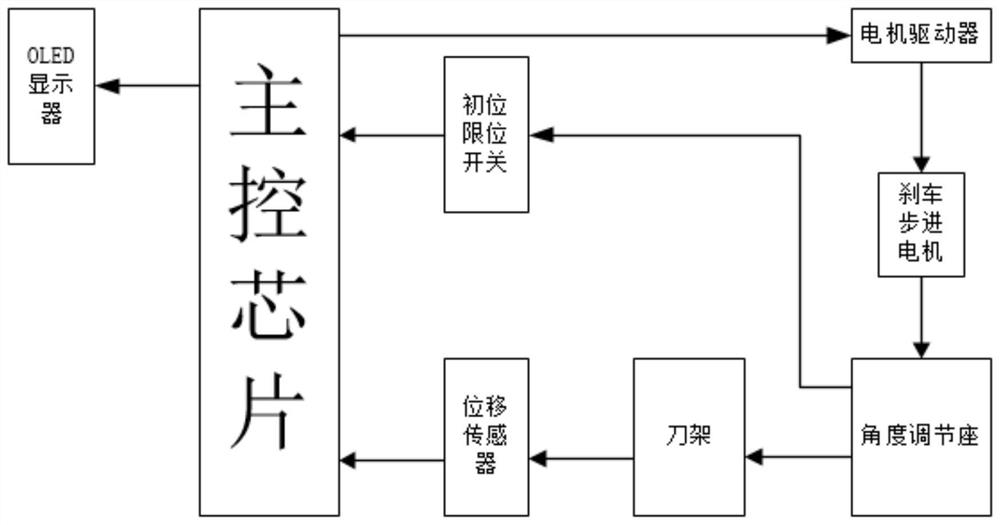

[0042] Such as figure 1 , 3 As shown, the rotary knife parallel adjustment control system includes a displacement sensor 10, a main control chip, a motor driver and an initial position limit switch; the displacement sensor 10 is installed on the tool holder 7, and there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com