Multi-channel composite electromagnetic filter dust-removing device

A technology of filtering and dust removal device and composite electromagnetic, which is applied in the direction of combination device, dispersed particle separation, chemical instrument and method, etc., can solve the problems of affecting gas passage, clogging of smoke and dust, difficult environmental treatment, etc., so as to prolong the service life and reduce the Effects of stress loss and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

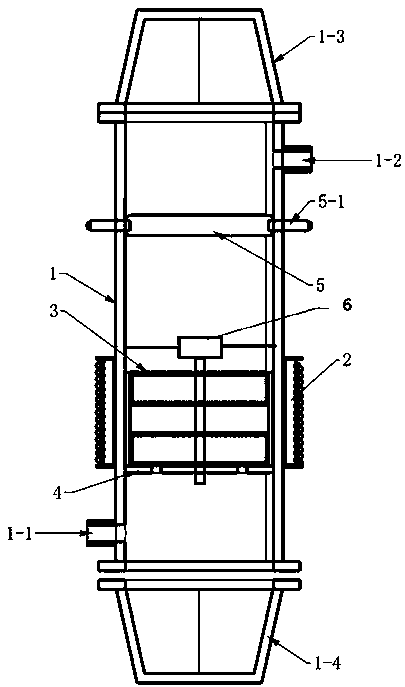

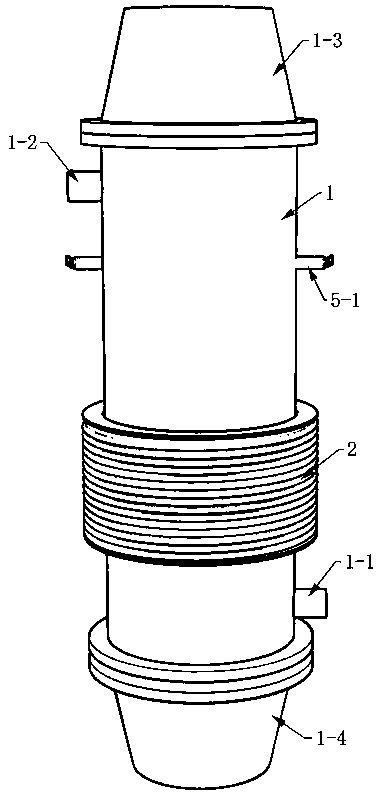

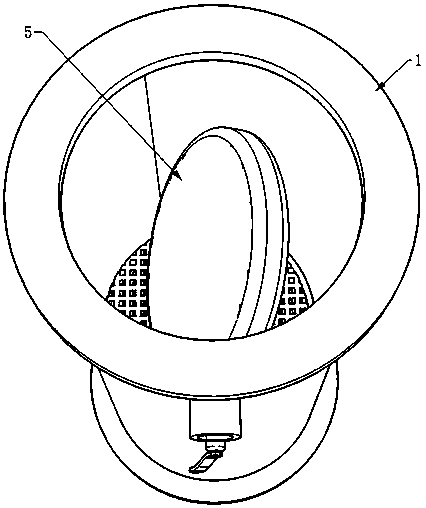

[0031] A multi-channel composite electromagnetic filter and dust removal device mainly includes a dust collector cylinder 1, a coil 2, and a filter layer structure 3, wherein the dust collector cylinder 1 is a cylindrical structure with no top and bottom, and the dust collector cylinder 1 There is a filter layer structure 3 in the internal clearance fit, and a porous filter 4 is detachably installed on the dust collector cylinder 1 close to the bottom of the filter layer. Specifically, four gaps can be processed evenly and symmetrically on the porous filter 4 (not shown in the figure), and four protrusions (not shown in the figure) are uniformly and symmetrically fixed (can be welded) on the inner wall of the dust collector cylinder 1. When installing the porous filter 4, put the porous filter 4 on the Align the four notches on the four protrusions on the inner wall of the dust collector cylinder 1, push upwards to make it higher than the four protrusions, and then rotate sligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com