Lily bulb core-breaking and segment-splitting equipment

A technology of splitting and lily, which is applied in the field of lily core breaking and splitting equipment, can solve the problems of mechanical damage of lily, achieve the effects of small mechanical damage, high splitting efficiency, improved mechanization and effective processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

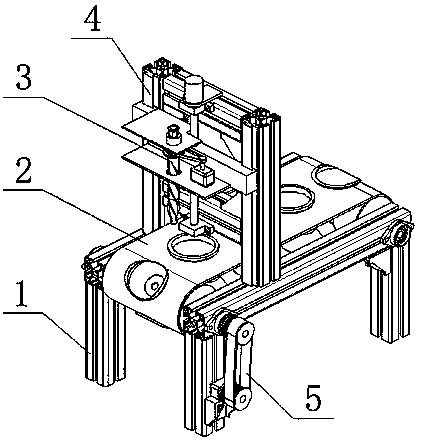

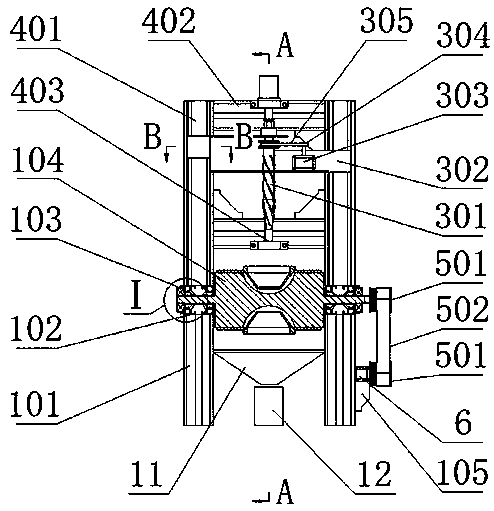

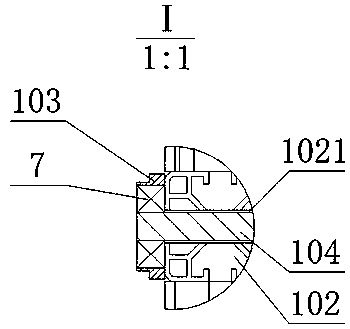

[0029] like figure 1 As shown, a lily core breaking and splitting device of the present invention includes a support 1 , a conveying device 2 , a splitting device 3 , a lifting device 4 and a power device 5 . like figure 2 As shown, the bracket 1 includes a support leg 101 and a crossbeam 102, two crossbeams 102 are provided, and the two crossbeams 102 are arranged in parallel, each crossbeam 102 is connected to two support legs 101, and the support legs 101 are provided with 4 pieces in total. ; Each beam 102 is provided with two shaft holes 1021, and the two shaft holes 1021 are respectively arranged at both ends of the beam 102; Figure 4 As shown, the transmission shaft 104 includes a shaft portion 1041, a connecting portion 1042 and a groove 1043, and the connecting portion 1042 is provided with two; as image 3 As shown, two connecting parts 1042 are respectively arranged at both ends of the shaft part 1041, a groove 1043 is arranged at the center of the shaft part 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com