Porphyra haitanensis processing equipment and using method thereof

A processing device and technology of laver, applied in the field of food processing, can solve the problems of complex operation procedures, influence acceptance, various ingredients, etc., and achieve the effects of reasonable color matching, reducing oil content and improving oil content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

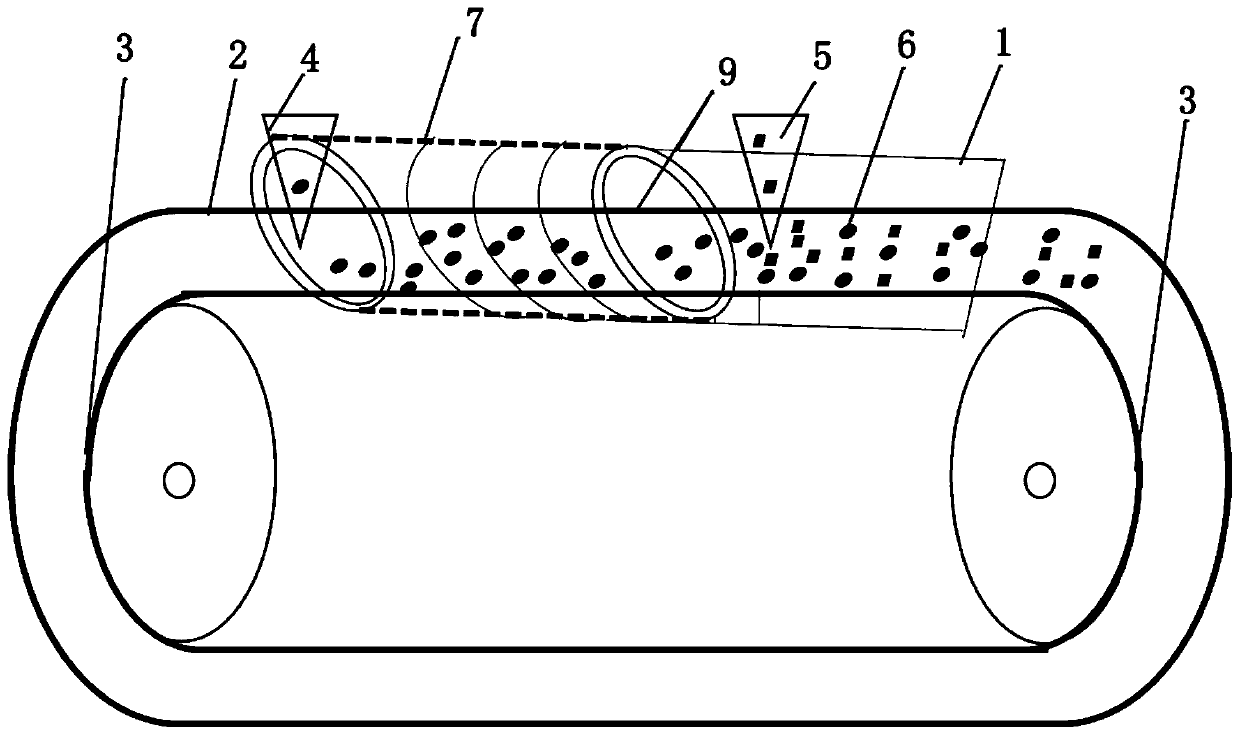

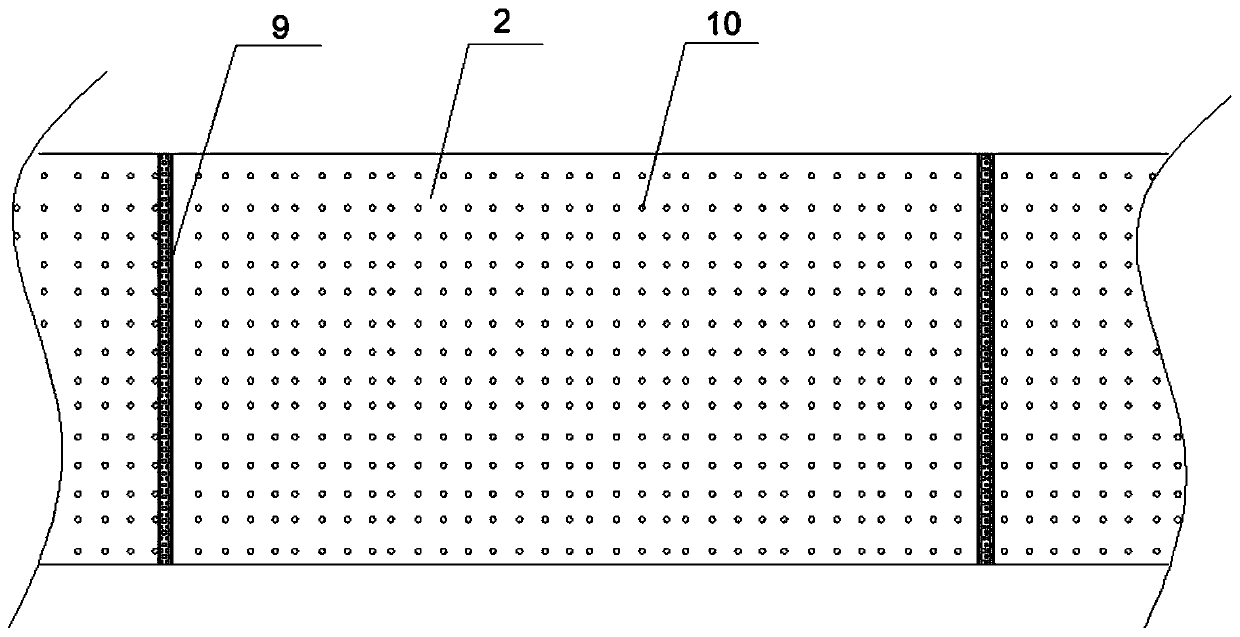

[0036] like Figure 1-3 Shown, a kind of altar laver processing device comprises ripening device, collecting device 1, stainless steel conveyer belt 2 and is positioned at the transmission wheel 3 of stainless steel conveyer belt 2 inner cavity both sides, is connected with the motor that drives it to rotate on the described transmission wheel 3 (Fig. not shown). The ripening device includes a peanut adding device 4, a peanut ripening device, a ripened peanut oil control device, an altar laver adding device 5, and a mixing device 6 for mixing ripened peanuts and altar laver, which are arranged sequentially from front to back along the running direction of the stainless steel conveyor belt 2, The collecting device 1 is located at the rear end of the mixing device 6 .

[0037] The peanut ripening device includes a double-layer stainless steel drum 7. The double-layer stainless steel drum 7 includes a stainless steel inner wall 701 and a stainless steel outer wall 702. There is ...

Embodiment 2

[0042] A kind of altar laver processing method, this method needs the laver peanut processing device of embodiment 1. The method includes the following steps:

[0043] (1) Preparation of peanuts and peanut oil

[0044] Collect naturally dried peanut kernels, with a long diameter of 0.8-1.5 cm, a transverse diameter of 0.5-1 cm, and a moisture content of 20-25%. Peanut oil source products sold on the market, as a carrier for peanut ripening, fill the gaps of peanuts, which is conducive to achieving uniform and efficient ripening. The water content of the cooked peanuts is 7%-15%, and the lipids are reduced to 37%-40%.

[0045] (2) Preparation of altar seaweed

[0046] Fresh altar laver is washed and dried as a raw material, or dried altar laver products currently on the market are selected. The water content is 8-15%, cut into flakes or granules with a size of 0.5-1.5 cm, and set aside. After frying, the moisture can be reduced to 3-7%, and the lipid content can be increas...

Embodiment 3

[0056] A kind of altar laver processing method, this method does not need by the processing device of embodiment 1. The method includes the following steps:

[0057] (1) Preparation of peanuts and peanut oil

[0058] Naturally dried peanut kernels are collected, and the peanut oil source is sold on the market.

[0059] (2) Preparation of altar seaweed

[0060] Choose dried altar laver products currently on the market. The water content is 15%, cut into flakes, the size is 0.5-1.5 cm.

[0061] (3) Peanut ripening

[0062] In an ordinary iron pot, put peanuts and oil, the oil is peanut oil sold in the market, the mass ratio is 100:10. Ignite and heat up, the temperature is controlled at 135-145°C, stirring is required, and the moisture content is about 20%. Fry for 4 minutes, which is related to the firepower and the amount of peanuts and oil. When there is an obvious smell of peanuts, it indicates that the ripening has been completed. If there is a lot of oil, you can con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com