Wind bell type friction nano-generator and manufacturing method thereof

A technology of nano generators and manufacturing methods, applied in the direction of friction generators, etc., can solve the problems of small wind energy, limited use scenarios, and inability to collect, and achieve the effects of easy portability, extensive collection, avoiding service life and using sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

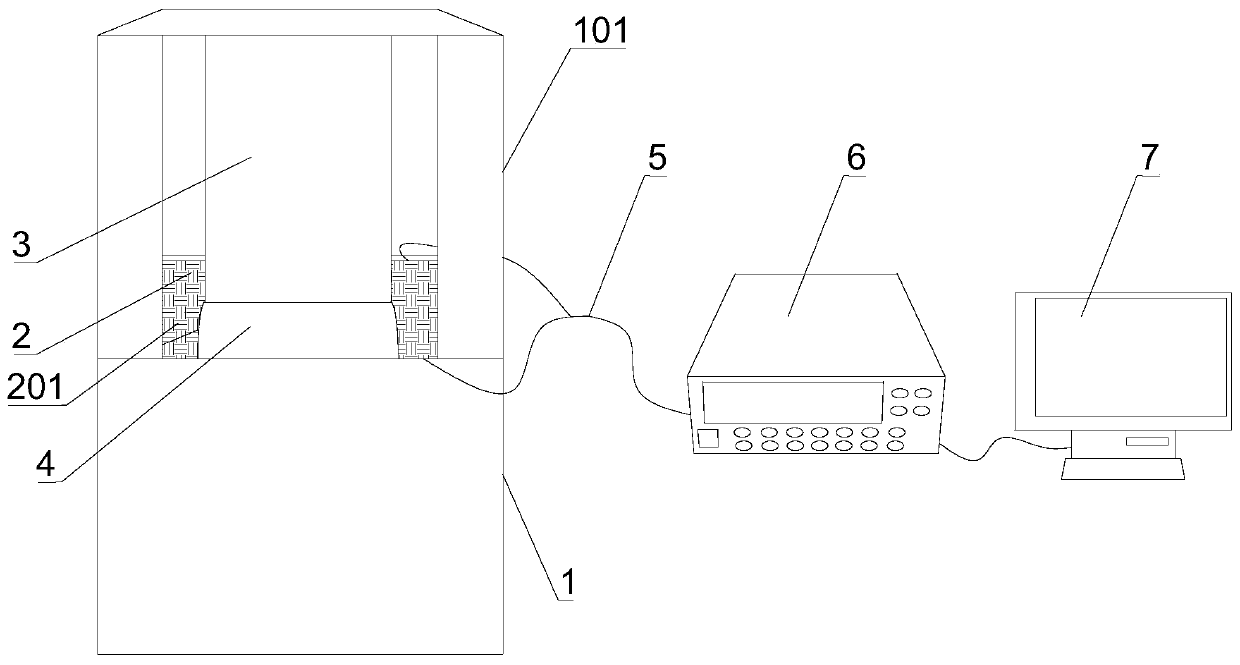

[0056] A preferred embodiment of the present invention provides a wind chime type friction nanogenerator, comprising a packaging cavity 1 and a swing unit arranged in the packaging cavity 1;

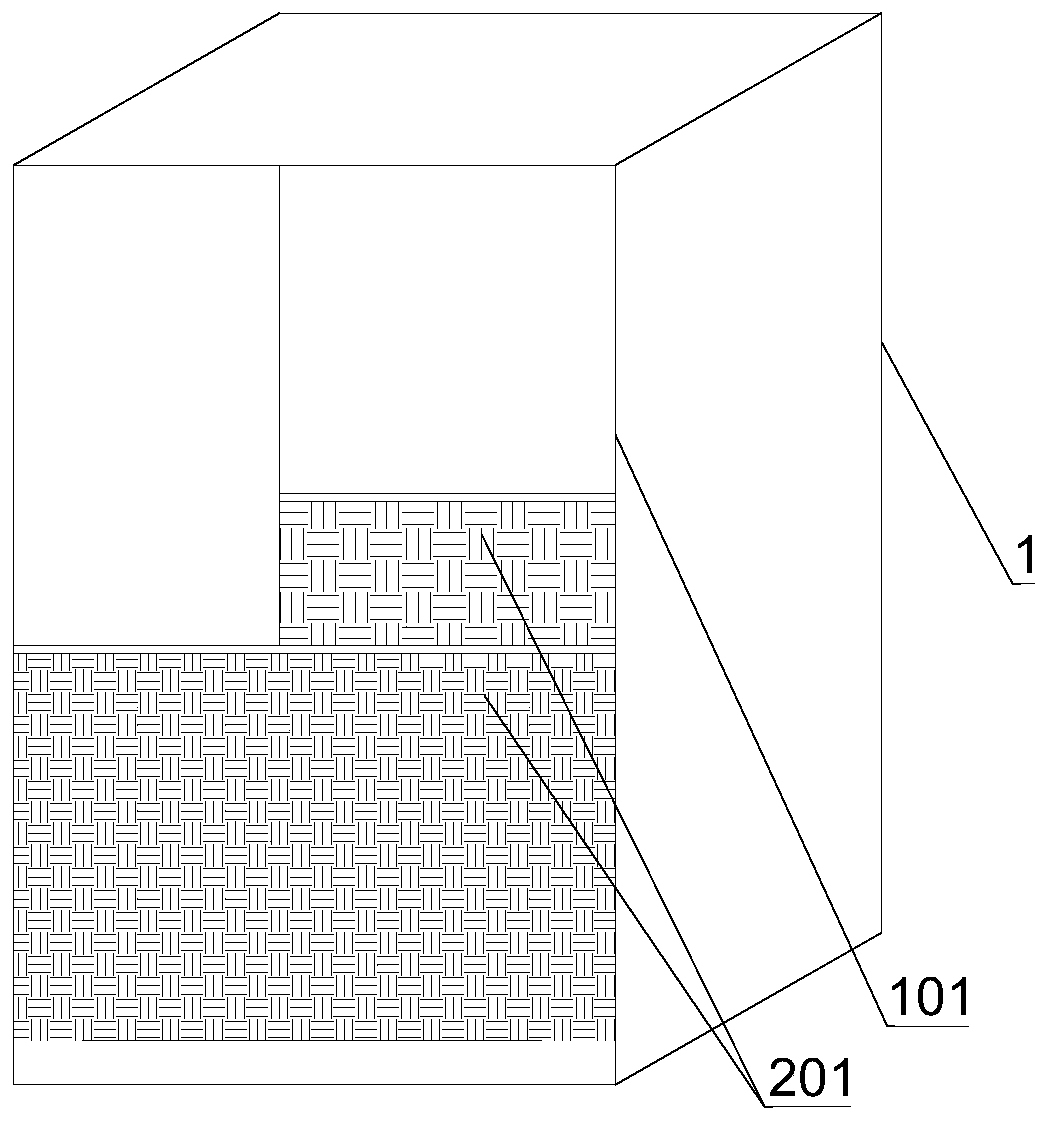

[0057] The encapsulation cavity 1 is provided with a vent 101, and an electrode 2 is provided inside, and the electrode 2 includes an electrode layer 201 disposed oppositely on the two inner surfaces of the encapsulation cavity 1;

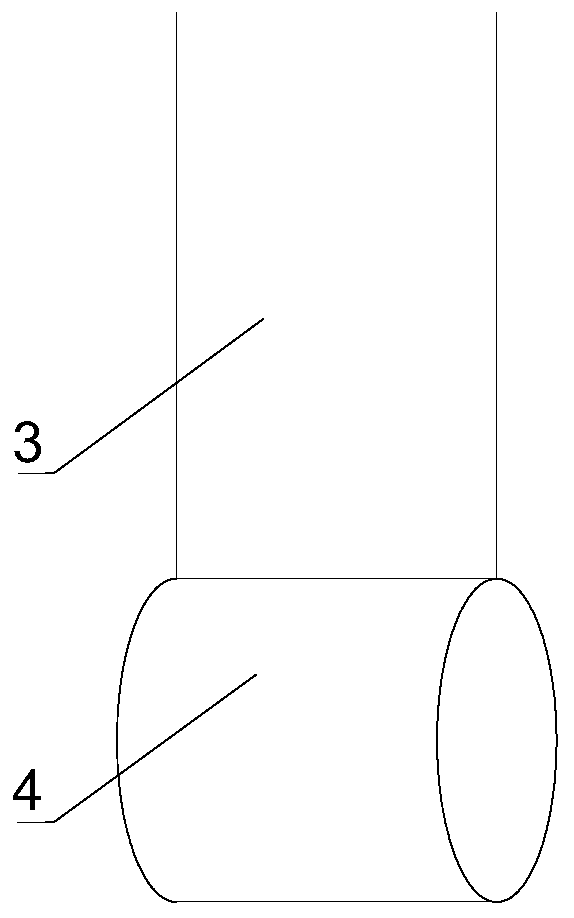

[0058] The swing unit includes a swing film 3 and a friction film. One end of the swing film 3 is connected to the top of the packaging cavity 1, and the other end is connected to the friction film to drive the friction film to swing. The friction film can be in contact with the electrode layer 2 during the swing process. .

[0059] Further, the friction film is a hollow cylinder friction film 4, the hollow cylinder friction film 4 is a cylinder formed by curling a rectangular film, and the material is a flexible organic polymer film material with friction ne...

Embodiment 2

[0079] In this embodiment, on the basis of Embodiment 1, further, a circular film 401 of PTFE material with a diameter of 2.5 cm is provided at the bottom circle of the hollow cylindrical friction film 4, facing the left side and the left side of the packaging cavity 1. Right.

[0080] Furthermore, the electrode 2 also includes electrode sheets 202 arranged on the other two inner surfaces of the packaging cavity 1, specifically arranged on both sides perpendicular to the axial direction of the hollow cylindrical friction film 4, and the height is the same as that of the circular film (401), etc. High, the electrode sheet 202 is a circular aluminum foil electrode with a diameter of 2.5 cm, located on the left and right sides of the packaging cavity 1, and two are arranged on one side, such as Figure 4 , Figure 5 shown.

[0081] Furthermore, the step 1 also includes sticking a circular film 401 of PTFE material with a diameter of 2.5 cm on the two bottom circles of the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com