A method for flip-chip bonding of ultra-thin wafer substrate chips with gold balls

A flip-chip welding and wafer technology, applied in the manufacturing of semiconductor devices, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problem that the packaging technology cannot meet the requirements of high density, and achieve simple design, high efficiency, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

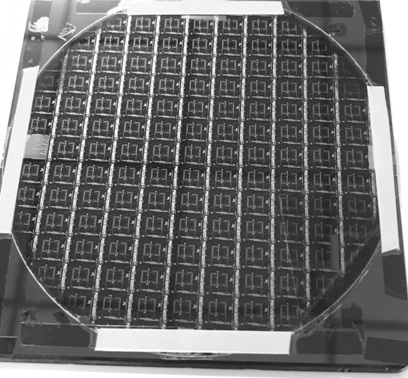

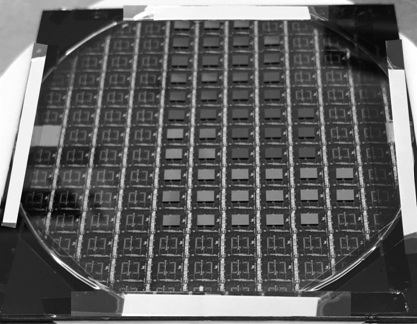

[0037] Chip gold ball flip-chip bonding test on a 4-inch GaAs wafer substrate with a thickness of 60 μm:

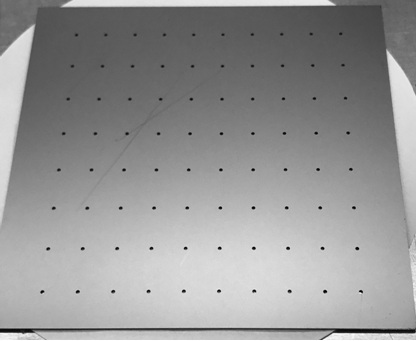

[0038] (1) Clean the 4-inch GaAs wafer substrate with a thickness of 60 μm with absolute ethanol, dry it in a 55°C oven for 10 minutes, and use hydrogen-argon plasma bombardment and inspection; clean the tooling carrier with absolute ethanol, and dry it in a 55°C oven 10min drying treatment;

[0039] (2) Place the 4-inch GaAs wafer substrate in (1) on the tooling carrier;

[0040] (3) Use high-temperature tape to paste along the four sides parallel to the tooling carrier, fasten the wafer substrate on the tooling carrier with high-temperature tape, and paste all the through holes in the tooling carrier with high-temperature tape;

[0041] (4) Use an automatic flip-chip mounter to flip-chip-bond the chip with the gold ball on the ultra-thin wafer substrate;

[0042] (5) The ultra-thin wafer substrate in (4) is diced by an automatic dicing machine.

[0043] It can be see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com