Three-phase three-dimensional non-circular transformer body structure

A non-circular, transformer technology, applied in the field of transformers, can solve the problems of reducing no-load current and third harmonic, increasing no-load loss of iron core materials, increasing the weight of coil wire materials, etc., to achieve low no-load loss and manufacturing costs. Low, energy-efficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

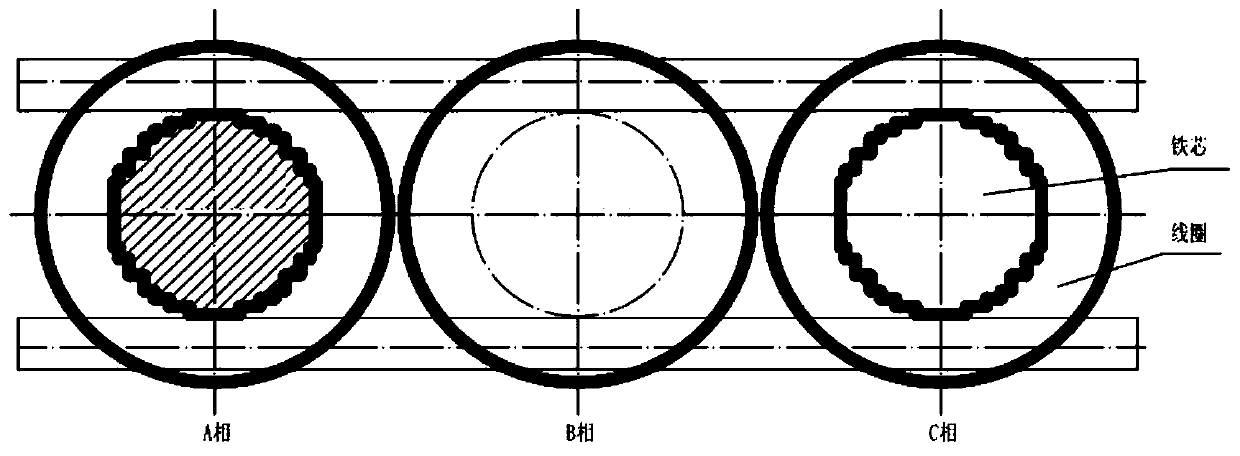

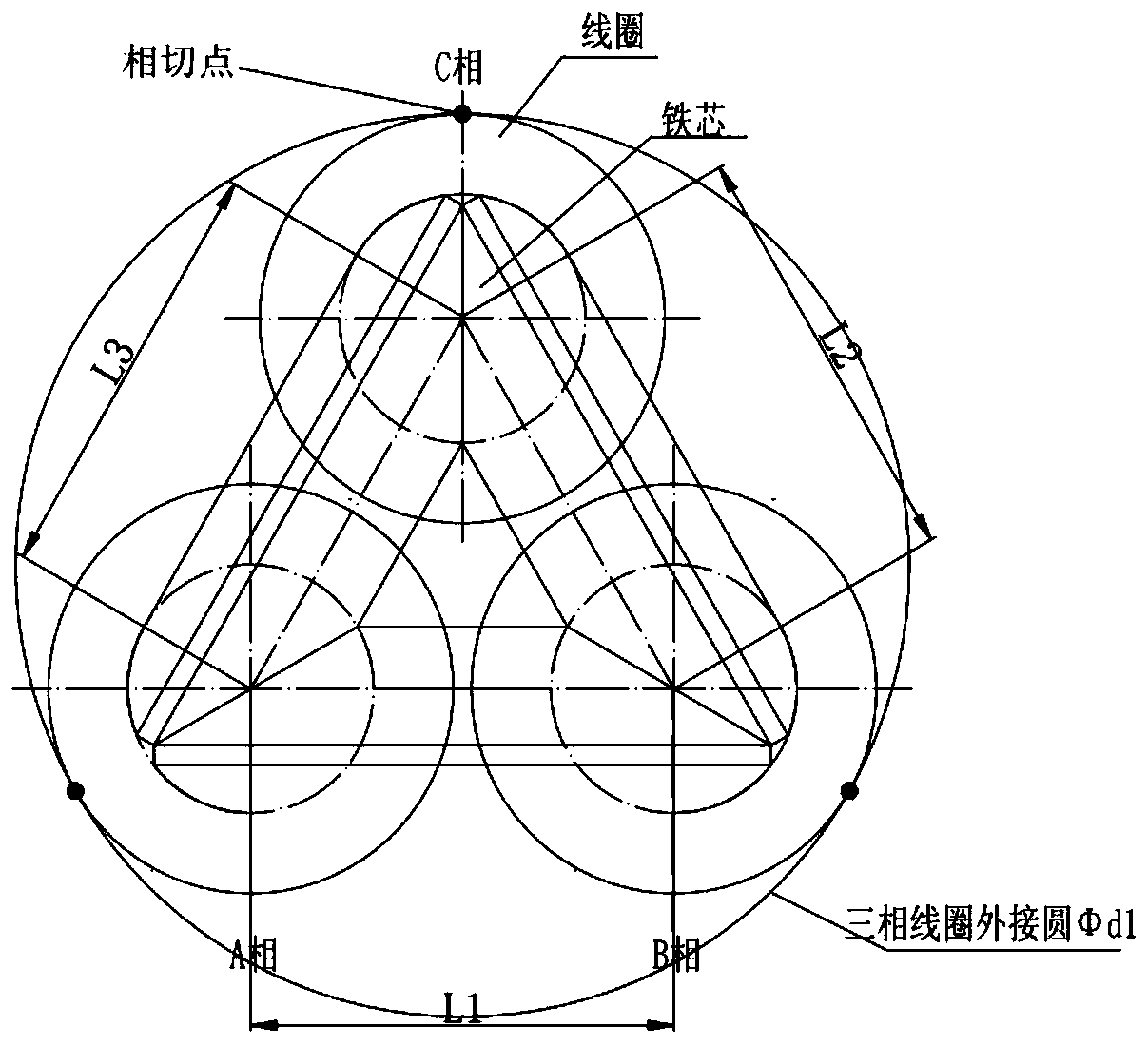

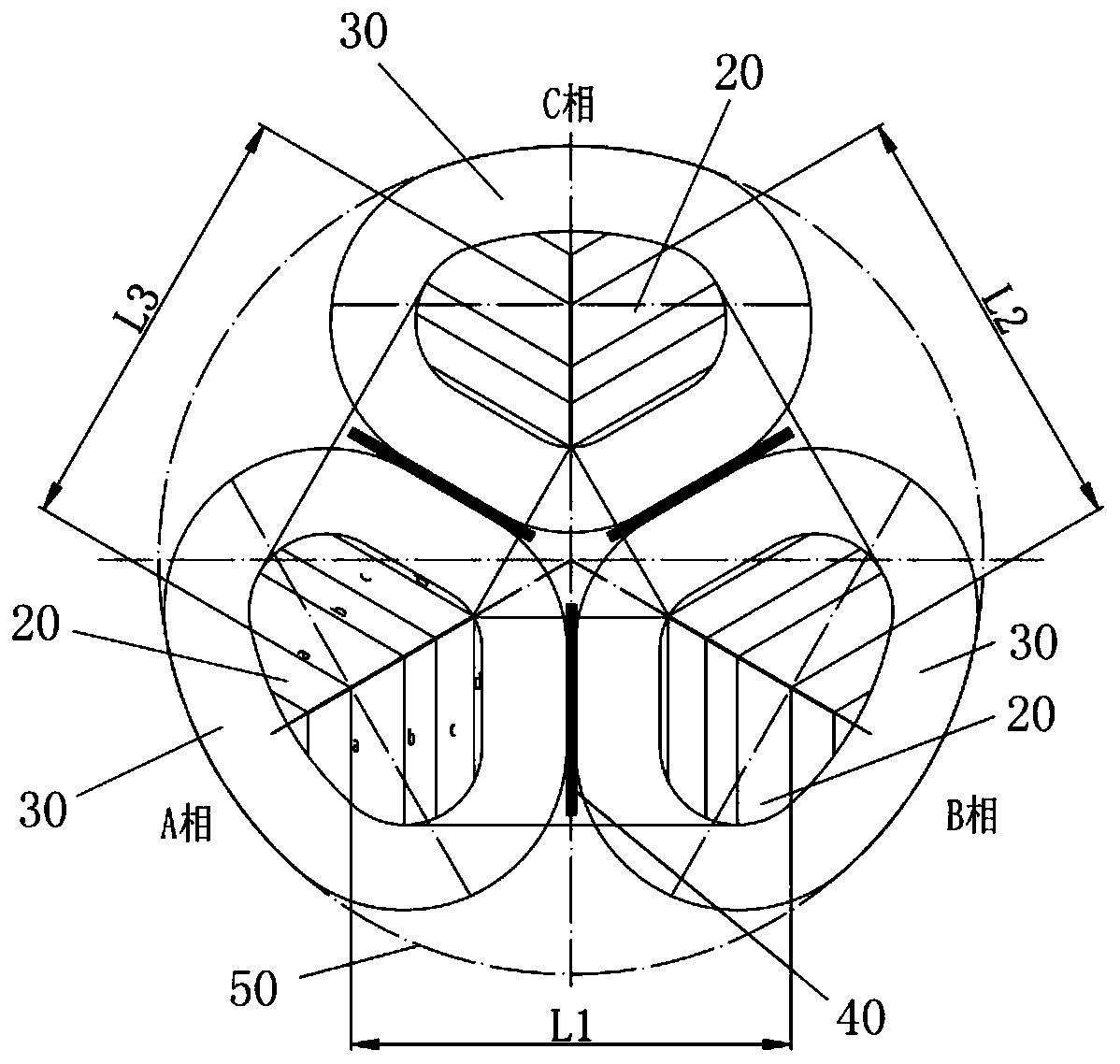

[0026] As shown in 3, a three-phase three-dimensional non-circular transformer body structure of the present invention includes an iron core and a coil group, the iron core includes three iron core columns 20, and the three iron core columns 20 have the same structural size, and The three core columns 20 are arranged perpendicular to the horizontal plane and parallel to each other. The horizontal sections of the three core columns 20 are all non-circular in shape. The horizontal sections of the three core columns 20 all have an arc edge. The coil set includes three coils 30 , and the three coils 30 respectively surround the three core legs 20 , and the three coils 30 are arranged perpendicular to the horizontal plane and parallel to each other. The shape and size of the three coils 30 are the same, and the horizontal cross-sections of the three coils 30 are all non-circular shapes, and the horizontal cross-sections of the three coils 30 all have an arc-shaped side. Three par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com