Fluorescent tracing method of Alpha-tricalcium phosphate hydration process

A tricalcium phosphate and fluorescent tracer technology, which is applied in the application field of bioactive fluorescent tracer technology, can solve problems such as inability to realize in-situ dynamic monitoring, affect clinical effects, and poor water resistance, and achieve continuous and stable luminescence performance, no Good biotoxicity and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

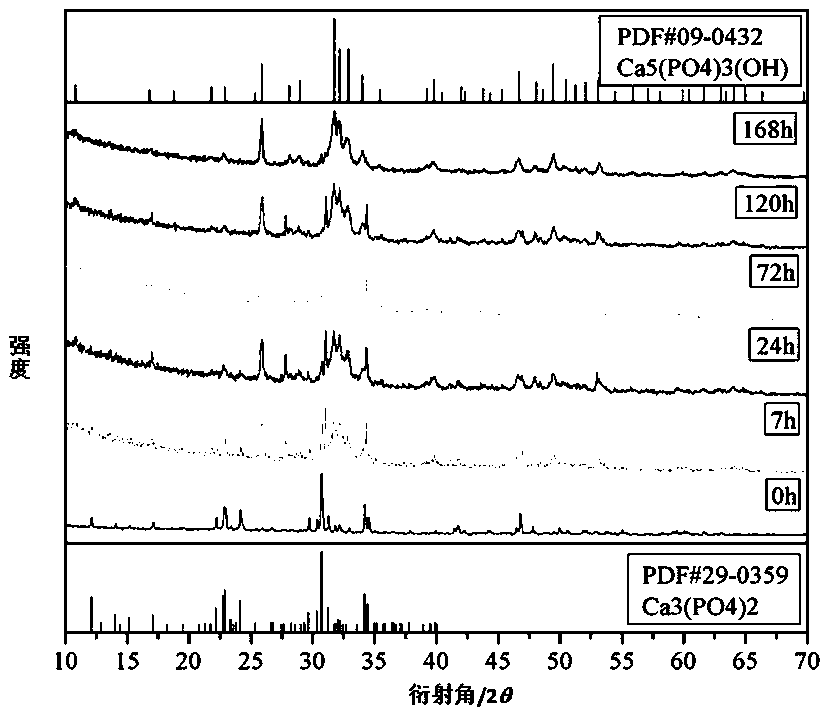

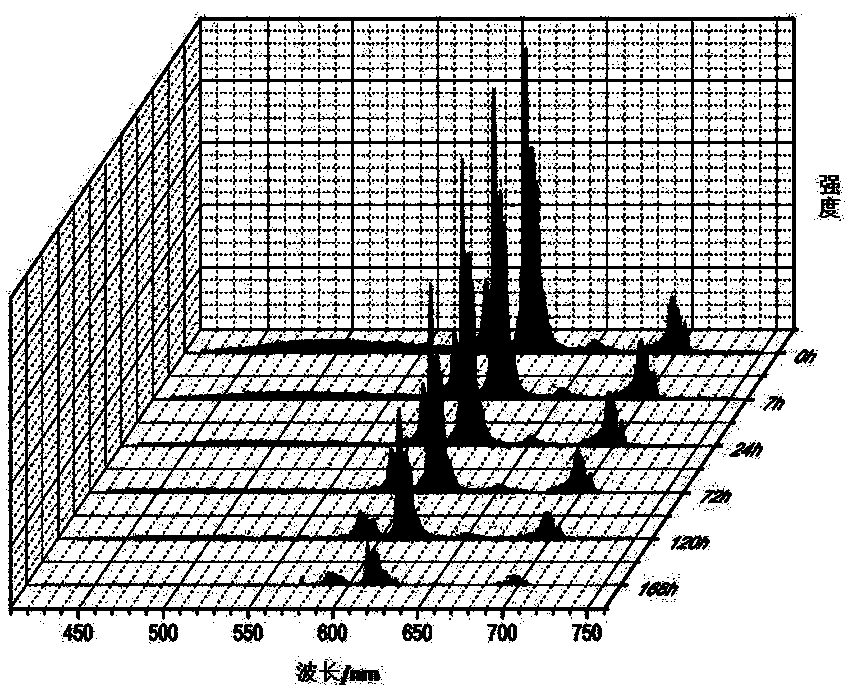

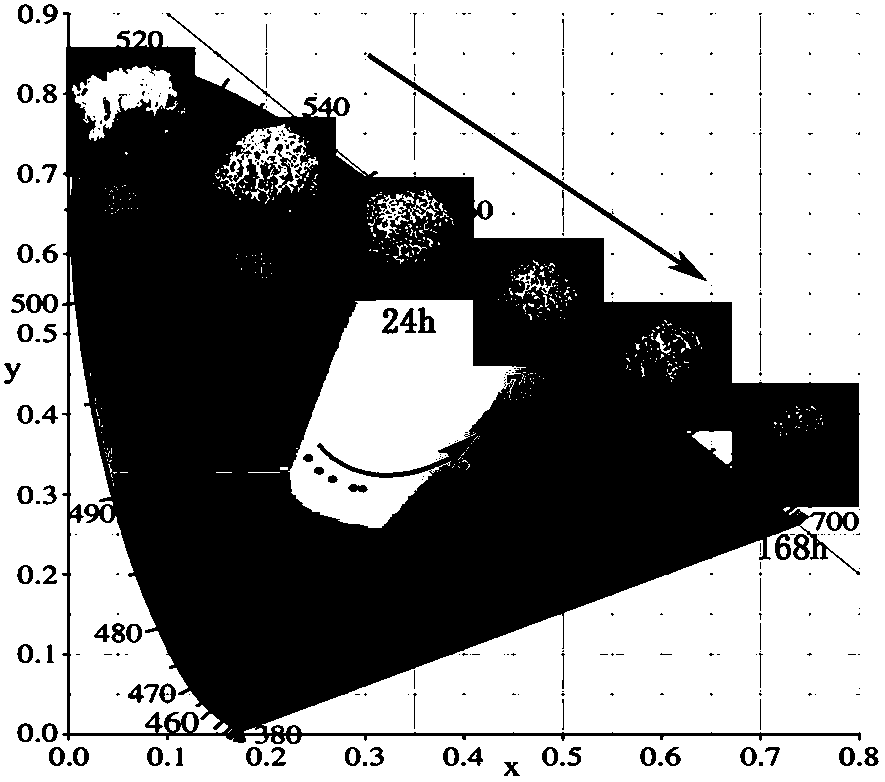

[0029] Take 1 gram of alpha-Ca 2.97 Eu 0.03 (PO 4 ) 2 Powder immersed in 100ml 0.25M K 2 HPO 4 Hydrate in the buffer solution, the pH value of the buffer solution is 7.4, the temperature is 37±2°C, and the hydration time is 0~168h. α-Ca that will be hydrated for different times 2.97 Eu 0.03 (PO 4 ) 2 The powder was taken out from the buffer solution, washed three times with deionized water, and then dried in a constant temperature box at 70°C for 12 hours. Finally, the content of hydroxyapatite in the hydrate was analyzed by XRD, and the excitation spectrum was detected by PL. , calculate the CIE color coordinates of its spectrum or / and take photos of fluorescence excited by 365nm ultraviolet light.

[0030] See attached figure 1 , which is the α-Ca prepared according to the technical scheme of this embodiment 2.97 Eu 0.03 (PO 4 ) 2 Comparison of X-ray powder diffraction pattern after hydration with standard cards PDF#290359 and PDF#090432.

[0031] See attached...

Embodiment 2

[0034] Take 1 gram of alpha-Ca 2.94 Eu 0.06 (PO 4 ) 2 Powder immersed in 100ml 0.25M K 2 HPO 4 Hydrate in the buffer solution, the pH value of the buffer solution is 7.4, the temperature is 37±2°C, and the hydration time is 0~168h. Ca that will be hydrated for different times 2.94 Eu 0.06 (PO 4 ) 2 The powder was taken out from the buffer solution, washed three times with deionized water, and then dried in a constant temperature box at 70°C for 12 hours. Finally, the content of hydroxyapatite in the hydrate was analyzed by XRD, and the excitation spectrum was detected by PL. , calculate the CIE color coordinates of its spectrum or / and take photos of fluorescence excited by 365nm ultraviolet light.

Embodiment 3

[0036] Take 1 gram of alpha-Ca 2.91 Eu 0.09 (PO 4 ) 2 Powder immersed in 100ml 0.25M K 2 HPO 4 Hydrate in the buffer solution, the pH value of the buffer solution is 7.4, the temperature is 37±2°C, and the hydration time is 0~168h. Ca that will be hydrated for different times 2.91 Eu 0.09 (PO 4 ) 2 The powder was taken out from the buffer solution, washed three times with deionized water, and then dried in a constant temperature box at 70°C for 12 hours. Finally, the content of hydroxyapatite in the hydrate was analyzed by XRD, and the excitation spectrum was detected by PL. , calculate the CIE color coordinates of its spectrum or / and take photos of fluorescence excited by 365nm ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com