Sewage treatment equipment fault monitoring system based on cloud computing

A sewage treatment equipment and fault monitoring technology, applied in computer control, general control system, control/regulation system, etc., can solve the problems of failing to find faults in time, failing to monitor hydraulic system faults, and failing to meet the stability needs of large sewage treatment plants and other issues, to achieve the effect of reducing data transmission energy consumption, saving physical space, and simple and convenient erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the following application scenarios.

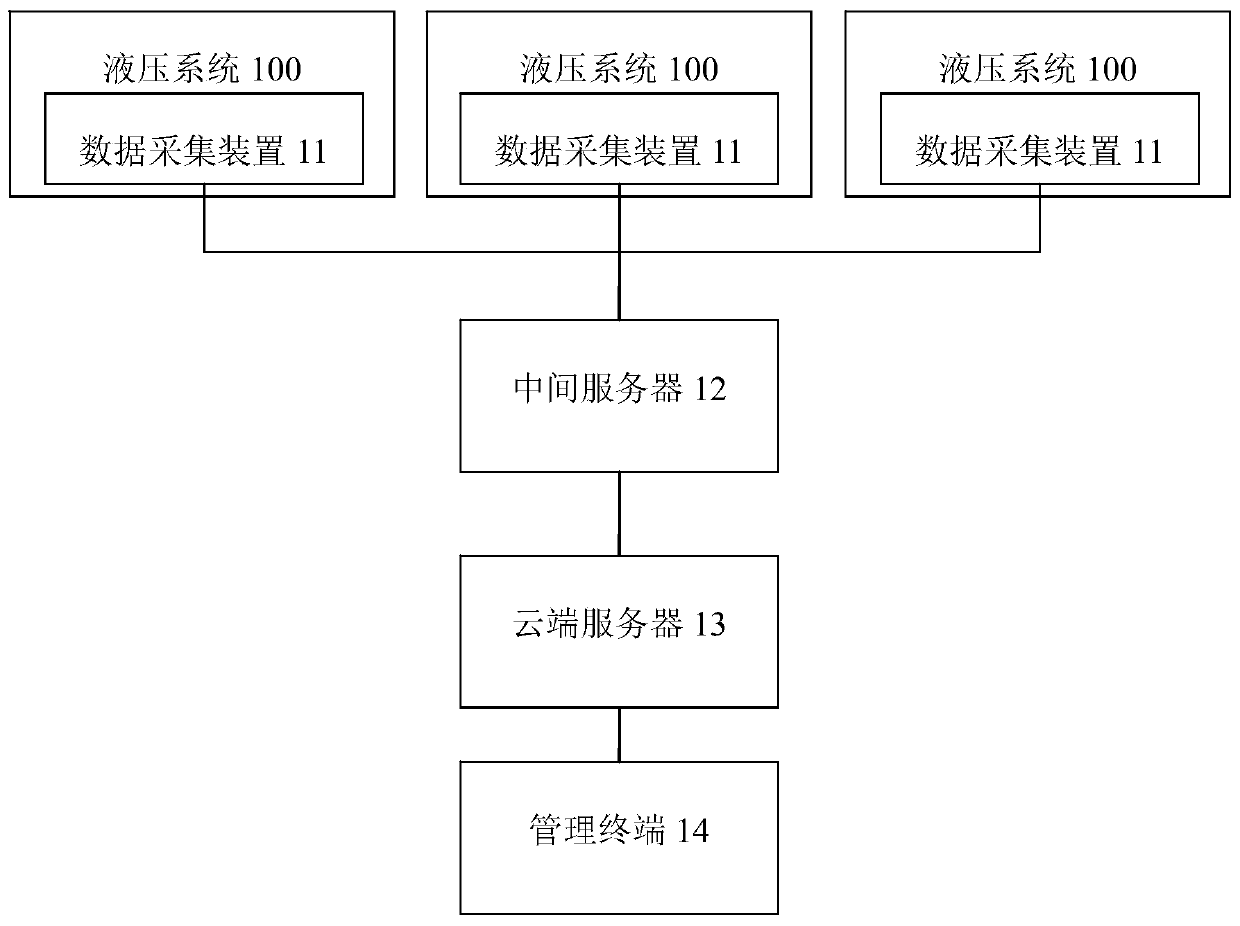

[0021] see figure 1 , which shows a sewage treatment equipment failure monitoring system based on cloud computing, wherein the sewage treatment equipment includes a hydraulic system 100, including: a data acquisition device 11, which is set in the hydraulic system 100 and used to collect the operation of the hydraulic system 100 status data, and the running status data is sent to the intermediate server 12; wherein the running status data includes pressure data, flow data and vibration data;

[0022] The intermediate server 12 is used to accept the running status data sent by the data acquisition device 11, and send the running status data to the cloud server 13 for fault monitoring processing;

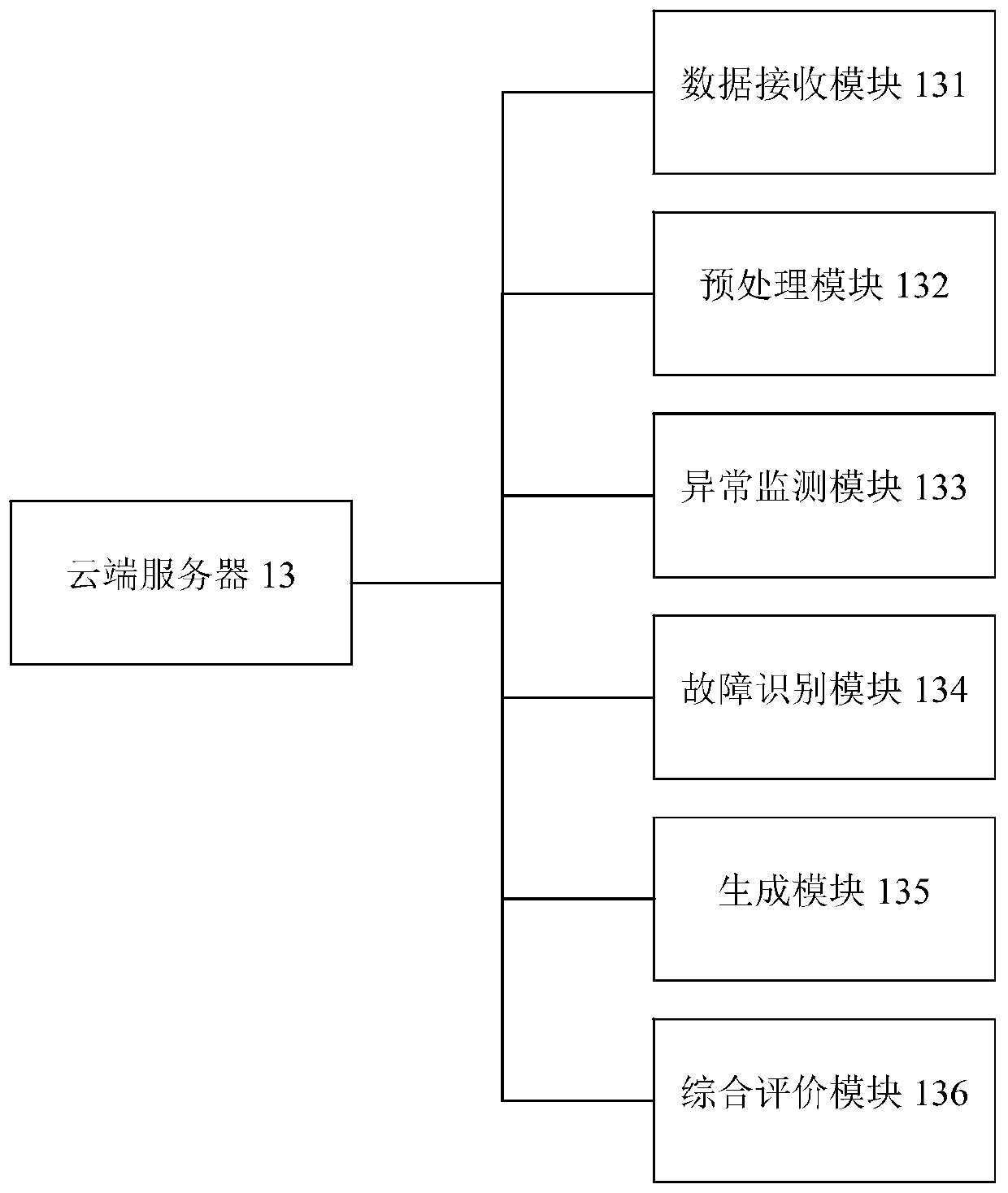

[0023] The cloud server 13 is used to monitor the faults of the running status data. When abnormalities are detected in the running status data, the running status data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com