Water-cooling single-end-face mechanical sealing structure and working method thereof

A technology of mechanical seals and working methods, which is applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of high temperature of the contact end surface of the moving ring and the static ring, leakage of the liquid delivered by the water pump, and burning of rubber seals, etc., to achieve water cooling Excellent effect and the effect of reducing the risk of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

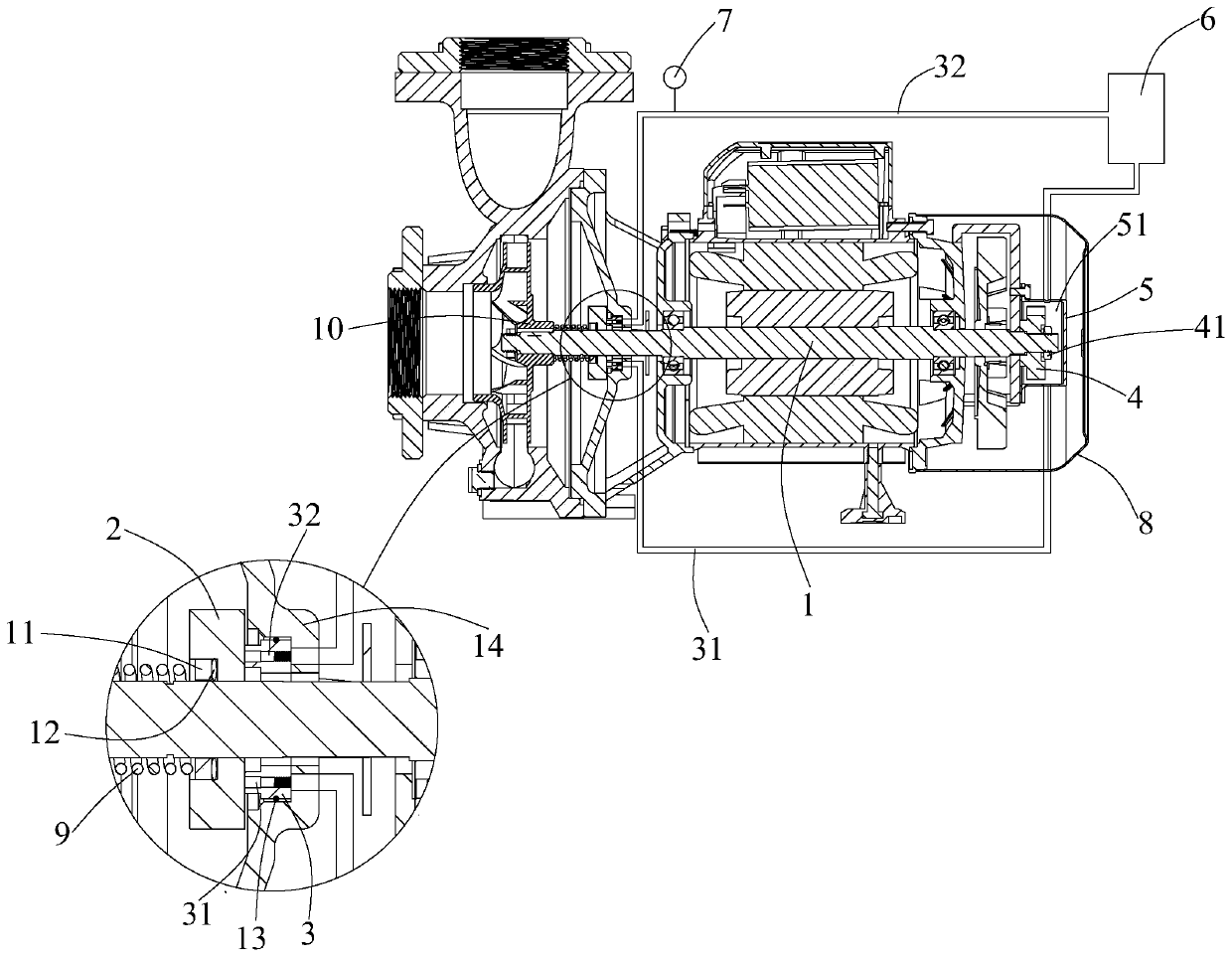

[0045] A water-cooled single-end mechanical seal structure, including a rotating shaft 1, a rotating wheel 10, a spring 9, a gasket 11, a first sealing ring 12, a moving ring 2 and a static ring 3 arranged on the rotating shaft 1 in sequence, wherein the rotating wheel 10 is sleeved and fixed on one end of the rotating shaft 1, and the moving ring 2 can also be fixed on the rotating shaft 1 so that it can rotate synchronously with the rotating shaft 1. At the same time, the moving ring 2 has a concave arc for placing the gasket 11, and the gasket 11 and the A first sealing ring 12 is arranged between the moving rings 2, and the spring 9 is sleeved on the rotating shaft 1 between the runner 10 and the gasket 11. At this time, the spring 9 is in a compressed state, and the gasket 11 can be pressed. Make the first sealing ring 12 play a good sealing effect.

[0046] This application adopts a single-end mechanical seal structure. Compared with the double-end mechanical seal struct...

Embodiment 2

[0065] The single-end mechanical seal structure in the second embodiment has been disclosed in the first embodiment, so it will not be repeated here.

[0066] A water-cooled working method of a single-end mechanical seal structure,

[0067] It includes a rotating shaft 1, a moving ring 2 and a static ring 3 sleeved on the rotating shaft 1; a water inlet pipeline 31 and a water outlet pipeline 32 are arranged between the moving ring 2 and the static ring 3, and the water inlet pipe The channel 31 and the water outlet pipe 32 communicate with each other, wherein coolant is injected from the water inlet pipe 31 and discharged from the water outlet pipe 32 to cool the moving ring 2 and the static ring 3 .

[0068] The water-cooling working method of the single-end mechanical seal structure of the present invention has excellent water-cooling effect and reduces the risk of leakage caused by the temperature rise of the mechanical seal.

[0069] In this embodiment, an impeller 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com