Fabrication method of automobile brake disc

A technology of automobile brakes and prefabricated bodies, applied in chemical instruments and methods, mechanical equipment, friction linings, etc., can solve the problems of inability to quickly prepare medium-sized and large-scale structural parts, cumbersome process steps, and brake pad bonding, etc., to achieve optimization Effects of friction performance and mechanical strength, reduction of production cost, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

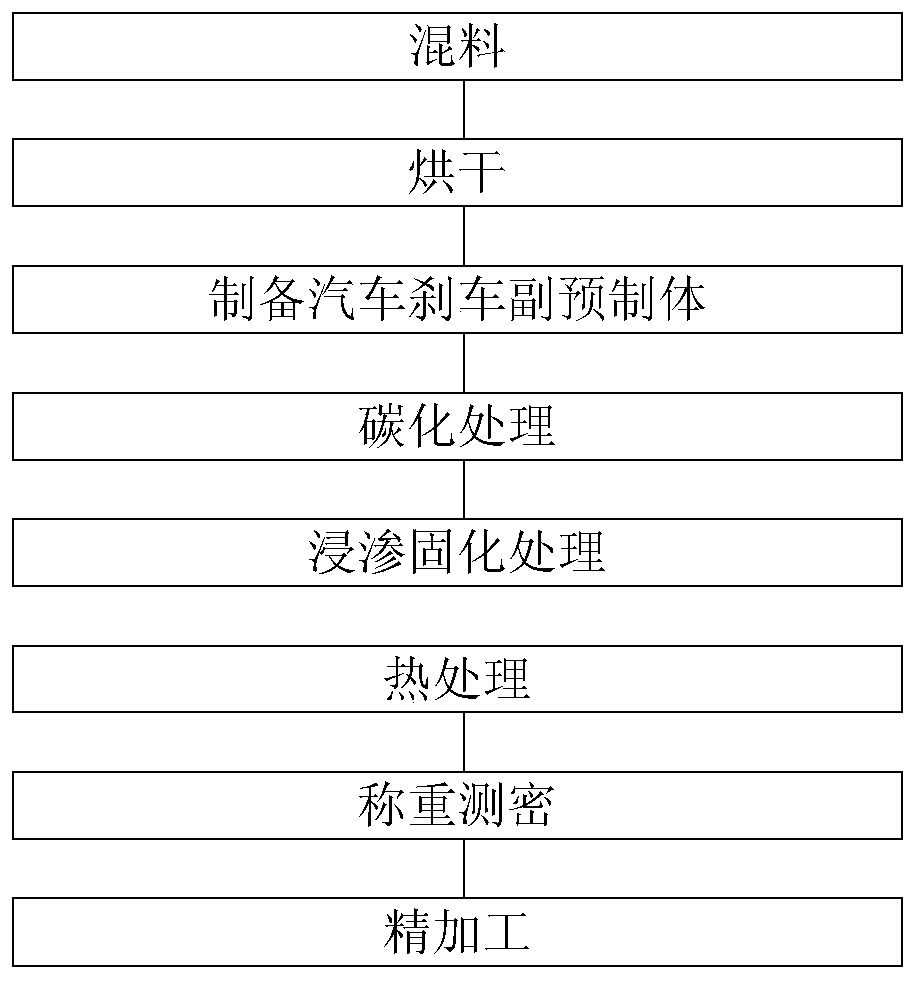

[0058] The invention is a method for preparing an automobile brake disc, and its specific technical scheme is described in detail through three embodiments. The specific process of each embodiment is the same.

[0059] Concrete process of the present invention is:

[0060] Step 1, mixing ingredients.

[0061] A mixture of chopped carbon fiber and modified aminophenolic resin is used as a prepreg, and the mass ratio of chopped carbon fiber to resin is 50%:50%; the ratio is a mass percentage.

[0062] The length of the chopped carbon fiber in the prepreg is divided into two types: 15mm and 30mm, and they are mixed in a ratio of 1:1.

[0063] Step 2, drying.

[0064] Evenly disperse the mixed prepreg on the tray for drying, the drying temperature is 65-75°C, and the drying time is 1-2h.

[0065] Step 3, prepare the prefabricated body of the automobile brake pair

[0066] The automobile brake pair prefabricated body is prepared by adopting the method of pre-compression-compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com