Prefabricated lattice beam for slope reinforcement, and manufacturing and construction method thereof

A lattice beam and prefabricated lattice technology, applied in manufacturing tools, infrastructure engineering, excavation, etc., can solve the problems of unguaranteed quality of cast-in-place concrete lattice beams, low overall mechanization, and reduced stiffness of components, etc. The effect of improving material utilization, reducing risk, and improving cross-sectional properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

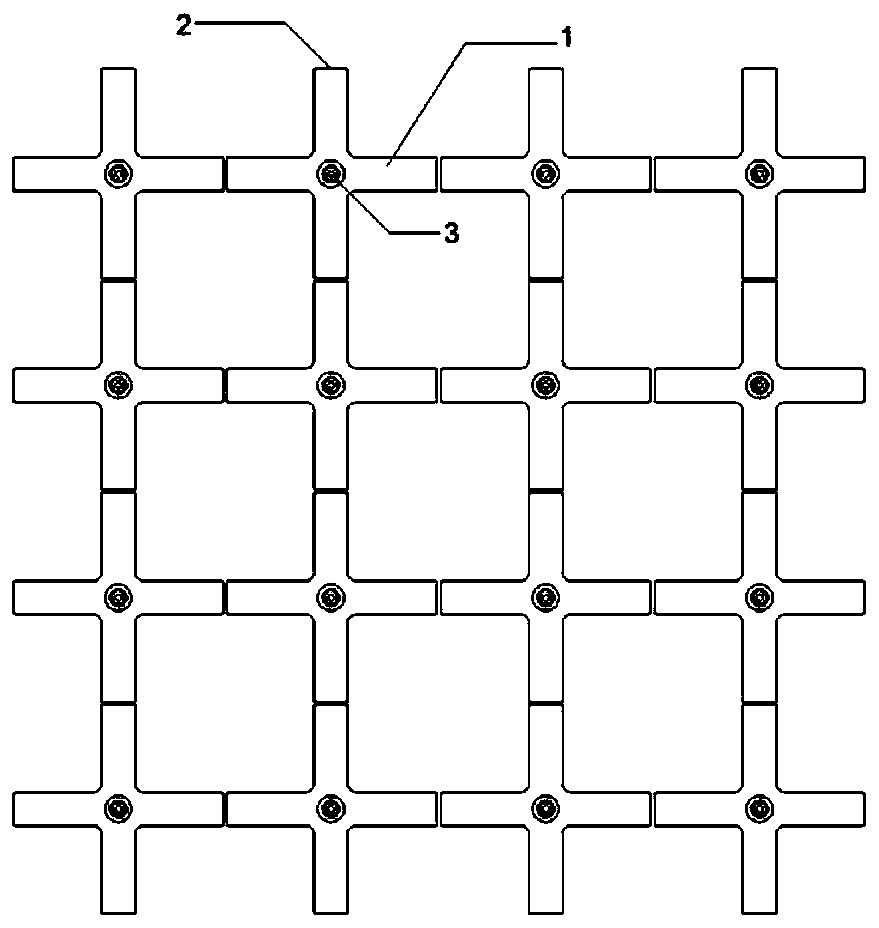

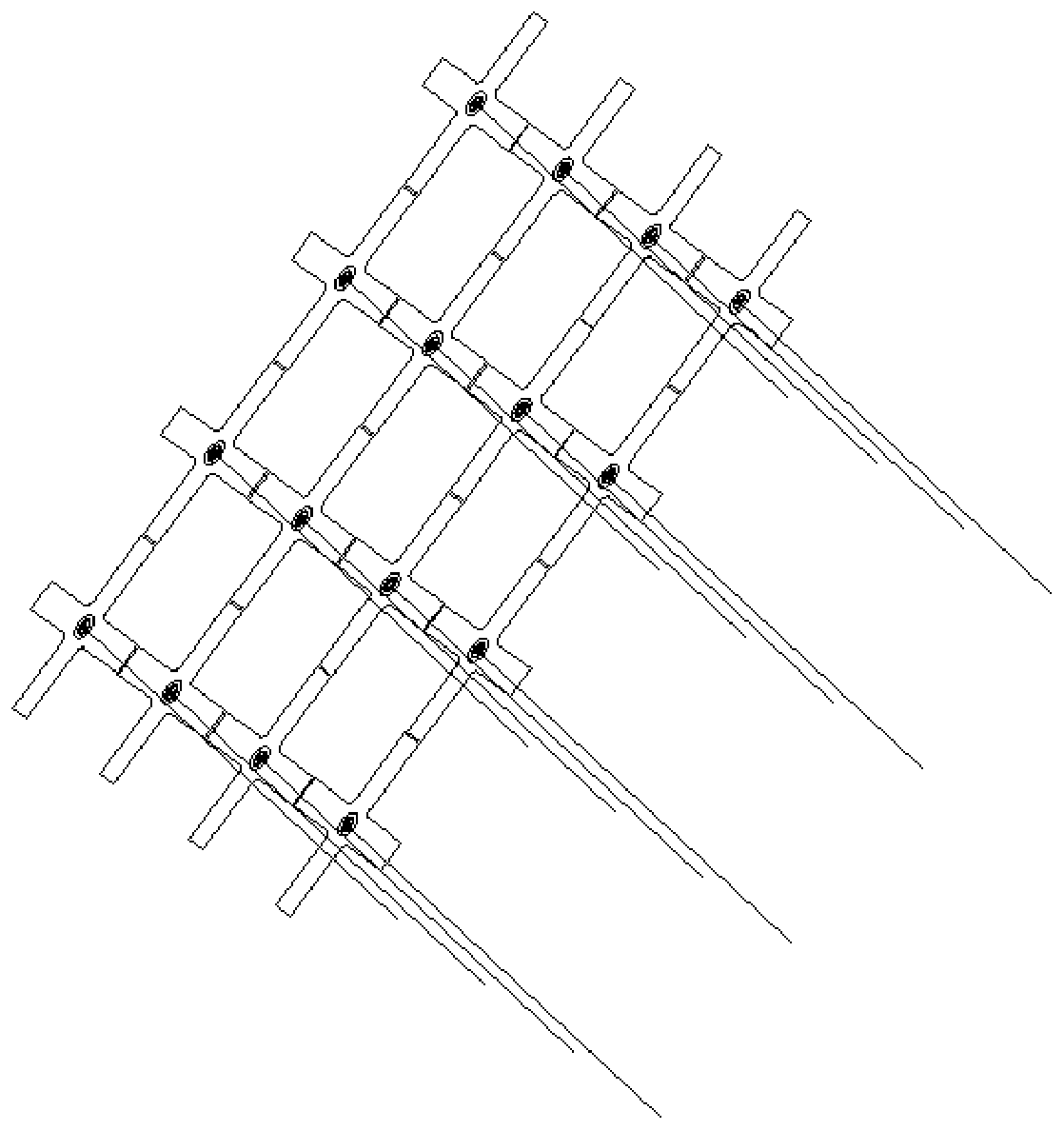

[0060] Such as Figure 1-13 As shown, the present invention relates to a prefabricated lattice beam for slope reinforcement, the prefabricated lattice beam is formed by laying and lapping a plurality of prefabricated cross-shaped beam units (1) in a matrix;

[0061] The prefabricated cross-shaped beam unit (1) is formed by cross beams (4) and longitudinal beams (5); an anchor head (7) ( Or called anchor cup); the corner (6) of the cross joint at the junction of the beam (4) and the longitudinal beam (5) is arc-shaped, so that the cross joint has better force-bearing performance;

[0062] The anchor head (7) includes a groove (8) and a backing plate (10) placed on the groove (8); the groove (8) and the backing plate (10) are provided with a Anchor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com