A paraffin/polyacrylonitrile intelligent temperature-regulating nanofiber

A technology of polyacrylonitrile and intelligent temperature adjustment, which is applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., and can solve the problems of poor coating effect of phase change fibers, easy loss of phase change materials, and insufficient latent heat of phase change. Excellent and other problems, to achieve excellent mechanical properties, avoid easy loss, and prevent the effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

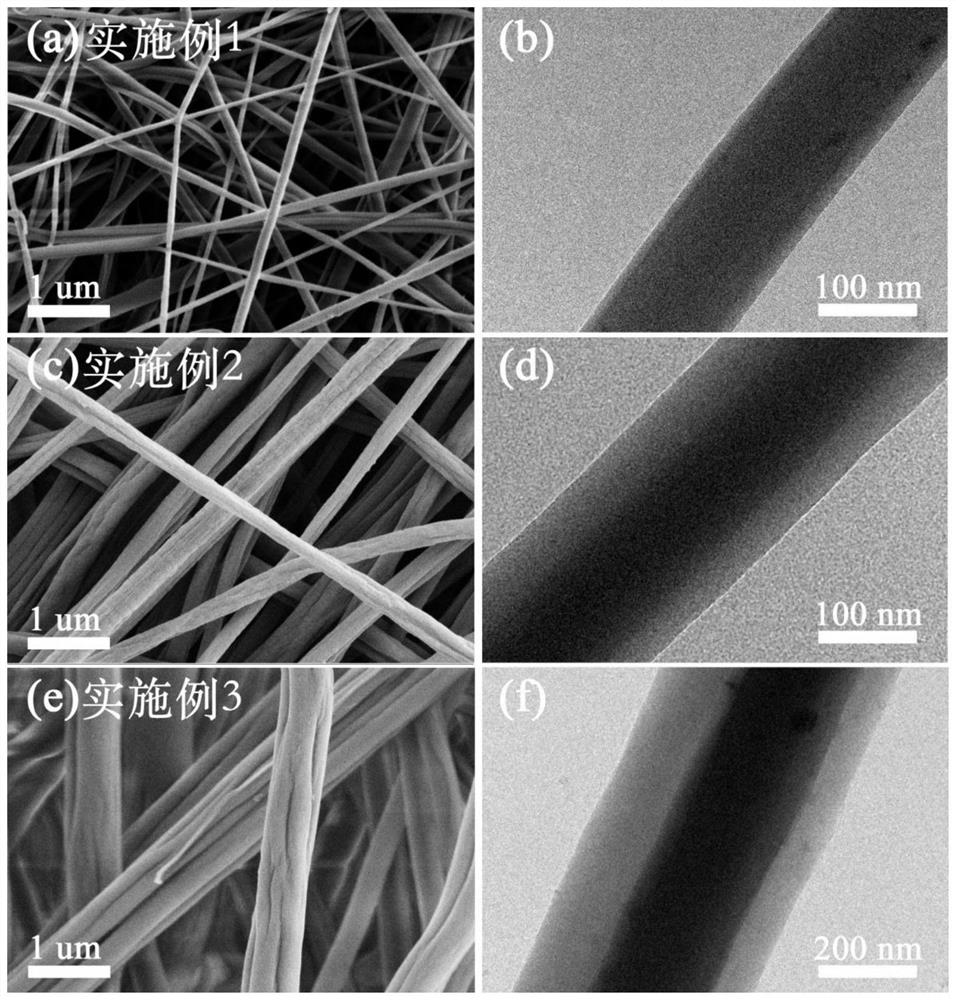

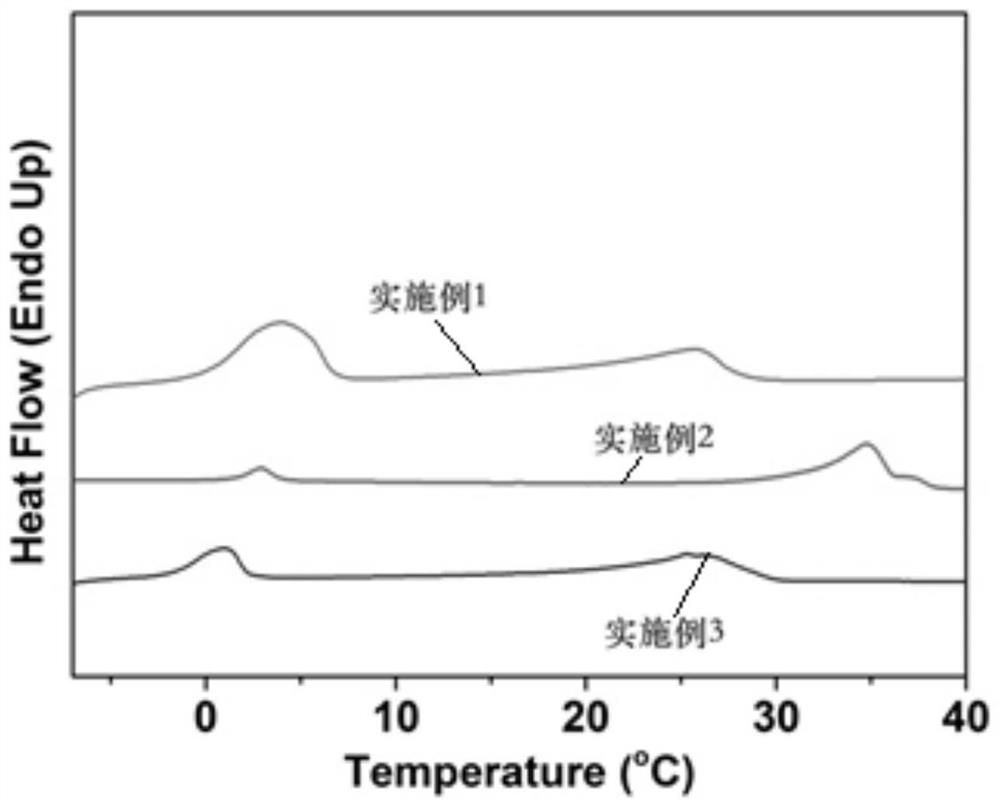

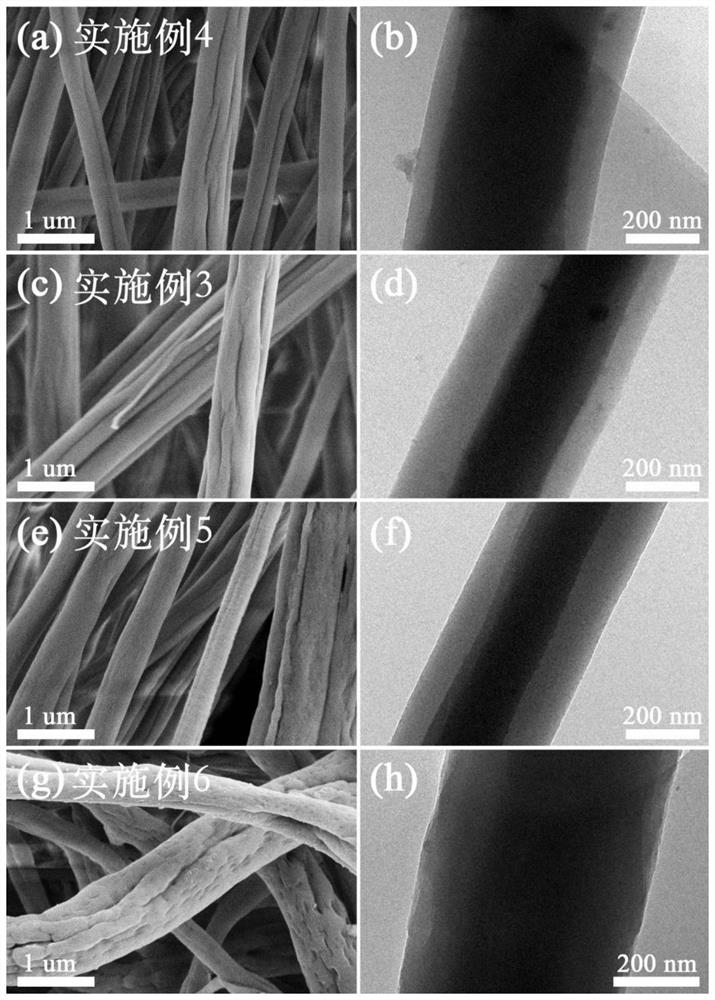

Embodiment 1

[0032] (1) Dissolve the washed PAN in DMF, place it on a magnetic stirrer and stir for 12 hours to prepare a homogeneous electrospinning solution with a mass fraction of PAN of about 10%, which is used as a cortex fiber-forming material for temperature-regulated fibers.

[0033] (2) Eicosane and tetradecane, which is liquid at normal temperature, are miscible with each other, and the mass ratio is 1:5, which is used as the core layer phase change material of the temperature-regulating fiber.

[0034] (3) Use the PAN solution as the outer phase spinning solution, and use the eicosane / tetradecane mixed solution as the inner phase spinning solution, transfer it to the syringe and add it to the coaxial nozzle, and spin in a high-voltage electrostatic field, The nanofibers are received by a drum covered with tinfoil. The external positive and negative voltages of the coaxial nozzle and the receiving drum are 13kV and -1.5kV respectively, the receiving distance is about 15cm, the ou...

Embodiment 2

[0036] (1) Dissolve the washed PAN in DMF, place it on a magnetic stirrer and stir for 12 hours to prepare a homogeneous electrospinning solution with a mass fraction of PAN of about 12%, which is used as the cortex fiber-forming material of the temperature-regulated fiber.

[0037] (2) Eicosane and tetradecane, which is liquid at normal temperature, are miscible with each other, and the mass ratio is 1:5, which is used as the core layer phase change material of the temperature-regulating fiber.

[0038] (3) Use the PAN solution as the outer phase spinning solution, and use the eicosane / tetradecane mixed solution as the inner phase spinning solution, transfer it to the syringe and add it to the coaxial nozzle, and spin in a high-voltage electrostatic field. The nanofibers are received by a drum covered with tinfoil. The external positive and negative voltages of the coaxial nozzle and the receiving drum are 13kV and -1.5kV respectively, the receiving distance is about 15cm, th...

Embodiment 3

[0040] (1) Dissolve the washed PAN in DMF, place it on a magnetic stirrer and stir for 12 hours to prepare a homogeneous electrospinning solution with a mass fraction of PAN of about 15%, which is used as the cortex fiber-forming material of the temperature-regulated fiber.

[0041] (2) Eicosane and tetradecane, which is liquid at normal temperature, are miscible with each other, and the mass ratio is 1:5, which is used as the core layer phase change material of the temperature-regulating fiber.

[0042](3) Use the PAN solution as the outer phase spinning solution, and use the eicosane / tetradecane mixed solution as the inner phase spinning solution, transfer it to the syringe and add it to the coaxial nozzle, and spin in a high-voltage electrostatic field, The nanofibers are received by a drum covered with tinfoil. The external positive and negative voltages of the coaxial nozzle and the receiving drum are 13kV and -1.5kV respectively, the receiving distance is about 15cm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com