A vacuum drum type polyester solid phase polymerization device

A technology of solid-phase polymerization and vacuum drum, which is applied in the field of solid-phase polymerization, can solve the problems of inconvenient single-person use, complicated use, complex device structure and process, etc., and achieve the effect of improving efficiency, simple operation, and improving fusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

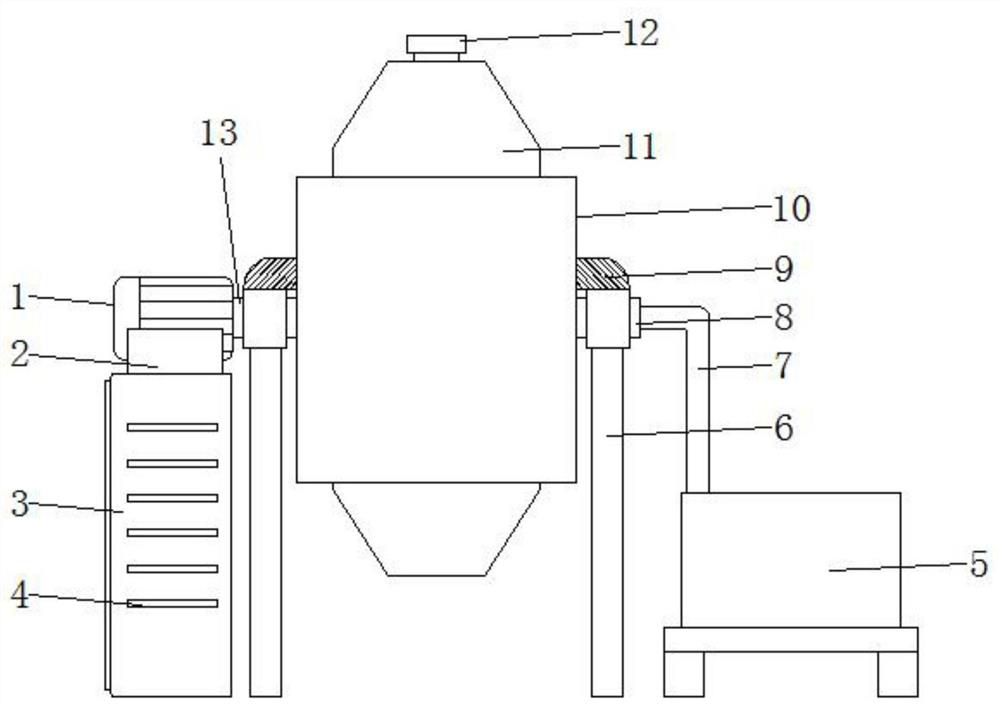

[0022] First implementation: see Figure 1 to Figure 4 , an embodiment provided by the present invention: a vacuum drum type polyester solid-phase polymerization device, including a control cabinet 3, a vacuum pump 5, a support 6, a heating layer 10 and a solid-phase polymerization kettle 11, and the solid-phase polymerization kettle 11 A first sealing cover 12 is threadedly installed on the feed pipe, and a hollow shaft 8 and an output shaft 13 are respectively fixed in the middle of both sides of the solid-phase polymerization kettle 11, and the solid-phase polymerization kettle 11 is installed on the Between the two brackets 6 , the end of the output shaft 13 away from the solid-phase polymerization kettle 11 is rotatably mounted on the motor 1 , and the length of the output shaft 13 is the same as that of the hollow shaft 8 .

[0023] The control cabinet 3 is located on one side of the bracket 6, and both sides of the control cabinet 3 are equidistantly provided with cooli...

no. 2 approach

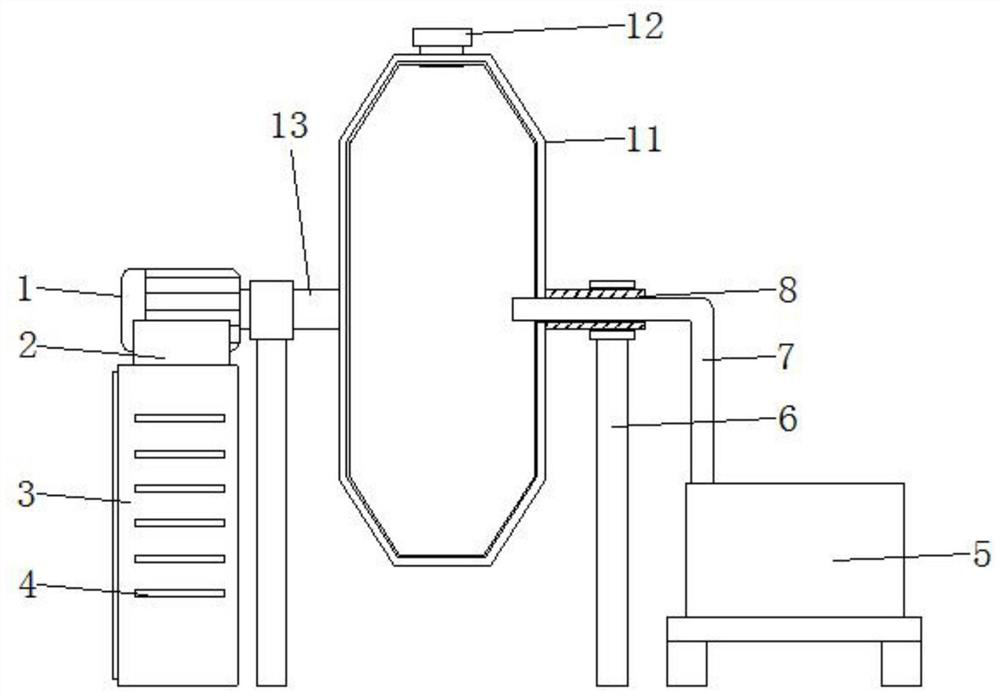

[0025] The second embodiment: a vacuum drum type polyester solid-phase polymerization device, including a control cabinet 3, a vacuum pump 5, a support 6, a heating layer 10 and a solid-phase polymerization kettle 11, the top of the solid-phase polymerization kettle 11 is fed The tube is provided with an insertion groove 14 with a first sealing cover 12 installed, and a hollow shaft 8 and an output shaft 13 are respectively fixed in the middle of both sides of the solid-phase polymerization kettle 11, and the solid-phase polymerization kettle 11 passes through the hollow shaft 8 and the output shaft 13 are rotatably installed between two brackets 6, the control cabinet 3 is located on one side of the bracket 6, and both sides of the control cabinet 3 are equidistantly provided with cooling outlets 4, and the upper part of the control cabinet 3 A buckle 2 is fixed in the middle of the end face, and a motor 1 is fixed inside the buckle 2. The vacuum pump 5 is located on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com